Textile Pretreatment: Lecture #8 – Optical Brightening Agents (OBAs)

Welcome back to our series on Textile Pretreatment! We’ve systematically worked our way through all the major physical and chemical cleaning and preparation steps: greige fabric inspection, singeing, desizing, scouring, bleaching, and heat setting. Our final stop in pretreatment, before we move onto dyeing, is a process that enhances the visual appeal of textiles: the application of Optical Brightening Agents (OBAs).

1. Introduction to Optical Brightening Agents (OBAs)

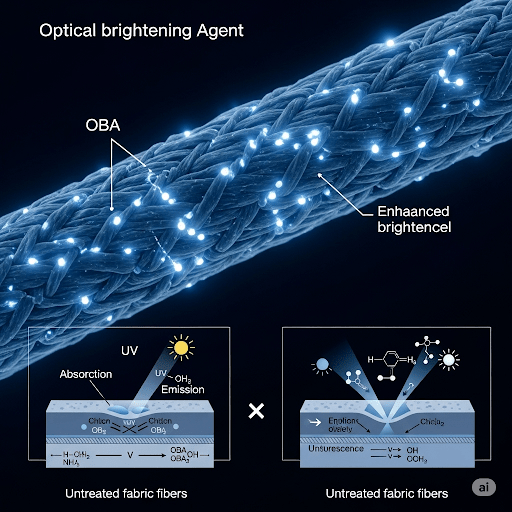

Optical Brightening Agents (OBAs), also known as Fluorescent Whitening Agents (FWAs), are colorless or faintly colored organic compounds that absorb ultraviolet (UV) light and re-emit it as visible blue-violet fluorescent light. They are not bleaches, but rather function by converting invisible UV radiation into visible light, making textiles appear whiter and brighter.

Why are OBAs Used?

Even after thorough bleaching, textile fibers often retain a slight yellowish tint due to residual natural pigments or degradation products. This yellowing subtracts from the perceived whiteness and brightness. OBAs counteract this yellowing:

- Enhance Whiteness: By emitting blue light, OBAs optically compensate for the yellow cast in the fabric, making it appear significantly whiter and brighter to the human eye. This is especially crucial for white goods (e.g., shirts, bed linens, towels) where a dazzling white is desired.

- Improve Color Brilliance: For pastel shades, OBAs provide a “whiter” base, making the pastel colors appear cleaner, clearer, and more vibrant.

- Counteract Yellowing Over Time: Some fabrics tend to yellow slightly with age or exposure to light; OBAs can help maintain their brightness.

- Cost-Effective Brightness: Can be a more economical way to achieve high apparent whiteness compared to aggressive bleaching methods.

2. The Science Behind OBAs

The magic of OBAs lies in their unique photophysical properties:

- Fluorescence: OBAs contain conjugated double-bond systems (chromophores) that allow them to absorb energy. Specifically, they absorb light in the ultraviolet (UV) region (around 340-380 nm).

- Energy Re-emission: Instead of simply absorbing the UV light and converting it into heat (like regular dyes), OBAs quickly re-emit this absorbed energy as visible blue-violet light (around 420-470 nm). This process is called fluorescence.

- Color Perception:

- The human eye perceives a textile with a yellowish tint because it reflects more yellow light and absorbs some blue light.

- When an OBA is present, it adds blue light to the light reflected from the fabric.

- This added blue light cancels out the yellow tint, making the fabric appear whiter and brighter than it actually is. It’s an optical illusion – the fabric isn’t chemically whiter, but it looks whiter.

- The total amount of light reflected from the fabric (including the emitted blue light) can even exceed 100% in the visible spectrum, leading to a “super-white” or “dazzling” effect.

3. Chemical Structure of OBAs

Most commercial OBAs are derivatives of:

- Stilbene: The most common class, providing strong blue fluorescence. They are derivatives of 4,4′-diaminostilbene-2,2′-disulfonic acid.

- Coumarin: Produce greenish-blue fluorescence.

- Pyrazoline:

- Naphthalimides:

- Benzoxazoles and Benzimidazoles: Often used for synthetic fibers.

OBAs are often sulfonated to make them water-soluble or dispersible, allowing them to be applied from an aqueous bath.

4. Application Methods of OBAs

OBAs can be applied at various stages of textile processing, often during bleaching or the final rinse. The specific method depends on the fiber type, the OBA’s chemical properties, and the desired effect.

- Exhaust Method: Fabric is immersed in a bath containing the OBA, and the OBA is adsorbed onto the fiber. Similar to dyeing, but no chemical reaction with the fiber in most cases; it’s a physical adsorption. Temperature and pH are controlled to optimize uptake.

- Padding Method: Fabric is run through a trough containing the OBA solution and then squeezed through rollers to ensure uniform impregnation. This is a continuous, high-speed method.

- Bleaching-cum-Brightening: OBAs are often applied directly in the hydrogen peroxide bleaching bath, combining two steps into one. This is efficient but requires careful selection of OBA to ensure stability in high pH and temperature.

- During Finishing: Can be applied in the final finishing bath for added flexibility.

- Detergent Formulation: Many household laundry detergents contain OBAs to make clothes appear brighter after washing.

5. Factors Influencing OBA Efficiency

- OBA Concentration: Too little, and the effect is minimal; too much, and it can lead to a greenish or dull white effect (“quenching” or “over-brightening”).

- Fiber Type: Different OBAs are specific to different fiber types (e.g., cellulosic, polyester, nylon).

- pH of Application: Each OBA has an optimal pH range for solubility, stability, and affinity for the fiber.

- Temperature: Influences the rate of OBA uptake.

- Presence of Residual Chemicals: Leftover bleaching chemicals or metal ions can interfere with OBA performance (e.g., cause dulling). Thorough washing before OBA application is important.

- Dyeing/Shade: For colored fabrics, the OBA can interact with the dye, affecting the final shade. For pastel shades, specific OBAs are chosen to avoid undesirable color shifts.

- Light Source: The apparent whiteness is highly dependent on the light source. Fabrics treated with OBAs look significantly whiter under UV-rich light (e.g., daylight) than under light sources lacking UV (e.g., some incandescent bulbs).

6. Fastness Properties

- Washfastness: Generally good to very good, depending on the OBA and fiber type. The OBA should remain on the fiber through multiple washes.

- Lightfastness: Can vary. Exposure to intense UV light over time can cause some OBAs to degrade, leading to yellowing of the fabric.

- Wet Fastness (e.g., perspiration): Good, but can be influenced by the OBA’s solubility and affinity.

7. Environmental and Safety Considerations

- Biodegradability: While generally considered safe for use, the environmental fate and biodegradability of various OBA types are continually studied.

- Aquatic Toxicity: Concerns exist regarding their impact on aquatic life, particularly for those that are highly water-soluble and not readily biodegradable.

- Regulatory Scrutiny: Some OBAs are subject to environmental regulations regarding their discharge into wastewater.

Optical brightening agents are a fascinating example of how optics and chemistry combine to enhance the aesthetic appeal of textiles. They are a common and effective tool in the textile industry for achieving dazzling whites and vibrant pastels.