The Enduring Popularity of Polyester: Textile Fiber Lecture #16 (in a Series on Textile Fibers)

Welcome back to our textile fiber lecture series! Today, we turn our attention to Polyester, a synthetic fiber that has become ubiquitous in the textile world. From the clothes we wear to the furnishings in our homes, polyester’s affordability, resilience, and adaptability have made it a dominant force in the industry. In this lecture, we will explore the history, preparation, and chemical structure of this enduringly popular fiber.

A Story of Innovation and Mass Adoption:

The research that led to the development of polyester dates back to the 1930s in both the United Kingdom and the United States. In the UK, John Rex Whinfield and James Tennant Dickson at Calico Printers’ Association patented polyethylene terephthalate (PET) in 1941. Meanwhile, Wallace Carothers and his team at DuPont, who had previously given us nylon, also conducted significant research into polyester polymers.

However, it was DuPont that truly brought polyester to commercial success in the 1950s under the brand name Dacron. Its wrinkle resistance and durability were heavily marketed, making it a popular choice for blending with natural fibers like cotton to improve their performance. Over time, various forms of polyester have been developed, each with slightly different properties, further expanding its applications.

Today, polyester is one of the most widely produced synthetic fibers globally, prized for its cost-effectiveness, ease of care, and versatility in mimicking the look and feel of various natural fibers.

Building Blocks of Resilience: Preparation and Chemical Structure

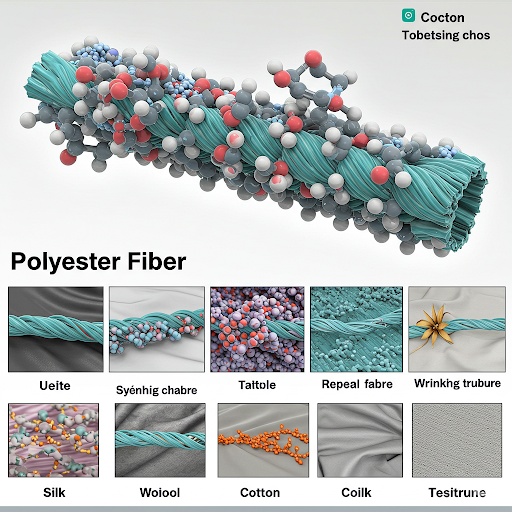

Polyester, in the context of textiles, most commonly refers to polyethylene terephthalate (PET). It is a synthetic polymer belonging to the polyester family, which is characterized by the presence of the ester functional group (-COO-) in its main chain.

Preparation of Polyester (PET):

PET is primarily produced through a process called esterification, involving the reaction of a dicarboxylic acid with a diol (an alcohol with two hydroxyl groups). There are two main routes for this process:

- Direct Esterification: This involves the direct reaction of terephthalic acid (TPA) with ethylene glycol (EG).

- Terephthalic acid: An aromatic dicarboxylic acid with the chemical formula C<0xE2><0x82><0x88>H₆O₄.

- Ethylene glycol: A diol with the chemical formula C₂H₆O₂ (HO-CH₂-CH₂-OH).

n HOOC-C₆H₄-COOH + n HO-CH₂-CH₂-OH → [-OC-C₆H₄-CO-O-CH₂-CH₂-O-]n + 2n H₂O - Ester Interchange (Transesterification): This older method involves the reaction of dimethyl terephthalate (DMT) with ethylene glycol.

- Dimethyl terephthalate: A dimethyl ester of terephthalic acid with the chemical formula C₁₀H₁₀O₄.

n CH₃OOC-C₆H₄-COOCH₃ + n HO-CH₂-CH₂-OH → n HO-CH₂-CH₂-OOC-C₆H₄-COOCH₃ + n CH₃OH n HO-CH₂-CH₂-OOC-C₆H₄-COOCH₃ → [-O-CH₂-CH₂-O-CO-C₆H₄-CO-]n + n CH₃OH

Chemical Structure of Polyester (PET):

The repeating unit of PET consists of an aromatic ring (benzene ring) derived from terephthalic acid and an ethylene glycol residue linked by ester linkages (-COO-).

The repeating unit’s structure can be visualized as:

O O

// //

-C - C₆H₄ - C - O - CH₂ - CH₂ - O -

\\ \\

Key Structural Features of Polyester:

- Polyester Chains: The long polymer chains are characterized by the presence of ester functional groups in the backbone.

- Aromatic Ring: The benzene ring in the terephthalic acid component contributes to the stiffness and thermal stability of the polymer.

- Polar Ester Groups: The polar ester groups allow for intermolecular interactions, contributing to the fiber’s strength and resilience, although these interactions are generally weaker than the hydrogen bonds found in nylon.

- Crystalline and Amorphous Regions: Similar to nylon, the arrangement of polyester polymer chains can result in both crystalline and amorphous regions. The degree of crystallinity significantly influences the fiber’s properties. Drawing (stretching) the fibers during manufacturing increases the alignment of the polymer chains, leading to higher strength and orientation.

In our next lecture, we will delve into the key properties of polyester fibers, exploring how this chemical structure translates into the characteristics that make it so widely used in the textile industry. We will discuss its strength, wrinkle resistance, hydrophobic nature, and other important attributes.

Thank you for your attention.