Textile Pretreatment: Lecture #4 – Scouring

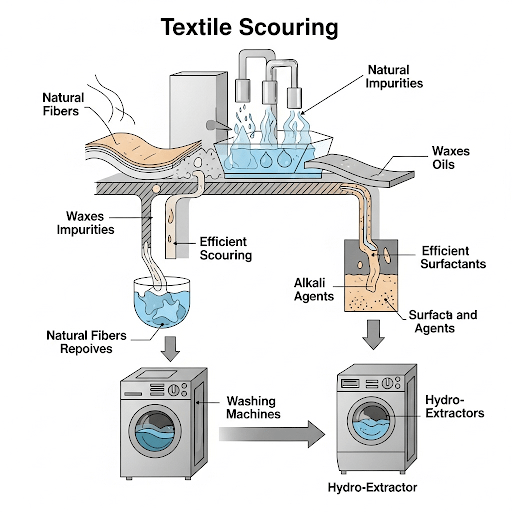

Welcome back to our series on Textile Pretreatment! We’ve covered the initial greige fabric inspection and the critical first wet process, singeing (for fuzz removal), followed by desizing (for size removal). Now, we move on to Scouring, a fundamental cleaning process aimed at removing the bulk of the natural and adventitious impurities that remain on the fabric.

1. Introduction to Scouring

Scouring is a severe washing process, typically performed in an alkaline solution at high temperatures. Its primary objective is to remove the non-cellulosic impurities from natural fibers (especially cotton), and oils, greases, and dirt picked up during manufacturing.

Why is Scouring Essential?

Even after singeing and desizing, cellulosic fibers like cotton still contain significant amounts of natural impurities that make them non-absorbent and unsuitable for dyeing.

- Residual Natural Impurities (especially for cotton):

- Waxes and Fats: These are the primary culprits for cotton’s natural water repellency. Scouring emulsifies and saponifies (converts to soap) these fatty substances.

- Pectins: Gummy, sticky substances that contribute to fabric stiffness and reduce absorbency.

- Proteins: Can cause yellowness and reduce whiteness.

- Mineral Matter: Ash and soil particles.

- Natural Coloring Matter: Although some is removed in bleaching, scouring helps.

- Adventitious Impurities:

- Oils and Greases: Lubricants from knitting/weaving machinery, human oils, etc.

- Dirt and Soil: Picked up during handling and storage.

- Improved Absorbency/Wettability: Scouring is the key process that renders the fabric uniformly hydrophilic (water-loving) and highly absorbent. This is paramount for even penetration of dyes and other chemicals.

- Enhanced Whiteness: By removing colored impurities, scouring improves the fabric’s initial whiteness, preparing it for effective bleaching.

- Better Hand Feel: Removing waxes and pectins results in a softer, more desirable fabric feel.

- Prevention of Dyeing Defects: Ensures consistent dye uptake, preventing unlevelness, streaking, and dull shades.

2. The Scouring Process and Chemistry (for Cotton)

Scouring is typically carried out in a continuous range or in batch machines, often in conjunction with bleaching for efficiency.

Key Chemicals Used in Cotton Scouring:

- Caustic Soda (Sodium Hydroxide, NaOH): The primary scouring agent. It’s a strong alkali that:

- Saponifies Fats and Oils: Converts fatty acids (components of fats and waxes) into water-soluble soaps. Fat+NaOH→Glycerol+Soap (Sodium Salt of Fatty Acid)

- Hydrolyzes Pectins and Proteins: Breaks down these polymeric impurities into smaller, soluble fragments.

- Dissolves Hemicelluloses and Natural Pigments: Helps remove other non-cellulosic components.

- Wetting Agents (Surfactants): Crucial for:

- Improving Wettability: Reducing the surface tension of the water, allowing the alkaline solution to penetrate the fabric and fibers more easily.

- Emulsifying Oils and Greases: Helping to disperse non-saponifiable oils and greases into fine droplets, preventing their redeposition on the fabric.

- Dispersing Solid Particles: Keeping dirt and other insoluble impurities suspended in the bath, preventing redeposition.

- Common examples include non-ionic or anionic surfactants.

- Sequestering Agents (Chelating Agents): These are complexing agents that bind with undesirable metal ions (e.g., calcium, magnesium, iron) present in hard water or picked up from the fabric itself.

- Why use them? Metal ions can:

- Form insoluble precipitates with soaps (scum), leading to dulling or spots on the fabric.

- Catalyze the decomposition of hydrogen peroxide during bleaching (if done simultaneously or subsequently), leading to fiber damage.

- Cause catalytic tendering (damage) of the fiber itself.

- Examples: EDTA (Ethylenediaminetetraacetic acid), DTPA, NTA.

- Why use them? Metal ions can:

- Anti-creasing Agents (Optional): Sometimes added to prevent the formation of permanent creases, especially in continuous processing of delicate fabrics.

Process Conditions:

- Temperature: High temperatures are essential, typically 95−100∘C (atmospheric boil) or even higher (110−130∘C) in pressurized vessels for faster processing.

- Time: Dwell time can range from minutes (continuous) to hours (batch).

- Concentration: Typically 2-4% NaOH (on weight of fabric), along with 0.5-1.0% wetting agent and sequestering agent.

- Equipment: Can be done in batch machines (jiggers, jets) or, more commonly for large volumes, in continuous open-width scouring ranges that involve padding, steaming, and extensive washing.

3. Scouring of Other Fibers

- Synthetic Fibers (e.g., Polyester, Nylon): These fibers do not contain natural impurities like cotton. Their “scouring” is mainly a milder wash process to remove oils, greases, and dirt picked up during spinning, knitting, or weaving. It usually involves a neutral or mildly alkaline wash with surfactants.

- Wool: Scouring of wool (raw wool) is a much more complex process aimed at removing grease (lanolin), suint (dried perspiration), dirt, and vegetable matter. It’s done with mild alkalis (e.g., soda ash, ammonia) and non-ionic detergents to avoid damaging the sensitive protein fiber. This is usually done to raw wool before yarn or fabric formation. For woven wool fabric, a milder washing or “crabbing” process might be used.

4. Testing for Complete Scouring

The effectiveness of scouring is assessed by evaluating the fabric’s absorbency/wettability and whiteness.

- Absorbency Test (Drop Test): A drop of water is placed on the fabric surface.

- Good Scouring: The water drop is absorbed almost instantaneously (within 1-2 seconds).

- Incomplete Scouring: The water drop sits on the surface or spreads very slowly.

- Whiteness Assessment: Visual comparison against a standard or instrumental measurement using a spectrophotometer (whiteness index).

5. Environmental Considerations

- High BOD/COD: Scouring effluent contains high levels of dissolved organic matter (impurities from the fiber, saponified fats), leading to high Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

- Alkaline Effluent: The high pH of the effluent requires neutralization.

- Chemical Consumption: Significant consumption of water, energy, and chemicals.

- Recovery: Efforts are made to recover heat and sometimes chemicals from the scouring liquor.

Scouring is a crucial and intensive cleaning step that ensures the fabric is free of water-repelling impurities and possesses uniform and high absorbency, laying the groundwork for subsequent successful bleaching and dyeing processes.