Textile Dyeing and Dyes: Lecture #2 – The Diverse World of Dyes: Classification by Chemical Structure and Application

Welcome back to our series on Textile Dyeing and Dyes! In our first lecture, we introduced the fundamental concepts and the historical journey of textile dyeing. Today, we will begin to unravel the complexities of the colorants themselves by exploring the two major systems used to classify dyes: classification by chemical structure and classification by application method.

Understanding these classifications is crucial for comprehending how different dyes interact with various textile fibers and the processes involved in achieving successful and colorfast dyeing.

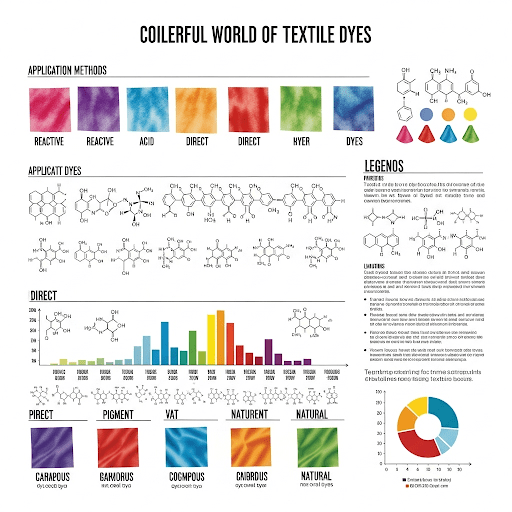

I. Classification of Dyes by Chemical Structure:

Dyes are organic compounds that contain chromophores (color-bearing groups) and auxochromes (color-enhancing and fiber-attracting groups). Classifying dyes based on their chemical structure provides insights into their inherent properties, such as color, light fastness, and wash fastness. While a detailed exploration of organic chemistry is beyond the scope of this lecture, understanding the major structural classes helps in appreciating their characteristics. Some important classes include:

- Azo Dyes (-N=N-): This is the largest and most versatile class of synthetic dyes, characterized by the presence of one or more azo groups (-N=N-). Azo dyes offer a wide range of colors and are used for dyeing various fibers with different application methods. They can exhibit good to excellent light and wash fastness depending on their specific structure. Examples include many direct dyes, acid dyes, and disperse dyes.

- Anthraquinone Dyes: These dyes are based on the anthraquinone structure and are known for their bright colors, particularly blues, violets, reds, and yellows, and generally exhibit good to excellent light and wash fastness. They are widely used as vat dyes, disperse dyes, and some reactive and acid dyes.

- Triarylmethane Dyes: This class features a central carbon atom bonded to three aromatic rings. They produce bright and intense colors, often with a greenish or bluish cast. Examples include basic dyes (cationic dyes) used for acrylic and modified polyester fibers, and some acid dyes for wool and silk. Their light fastness can vary.

- Phthalocyanine Dyes: These dyes have a large, stable ring structure containing a metal ion (often copper). They are known for their brilliant blues and greens and exhibit excellent light and wash fastness. Phthalocyanines are primarily used as pigment dyes and also in some reactive and disperse dye applications.

- Sulfur Dyes: These complex dyes contain sulfur linkages in their molecules and are typically applied to cellulosic fibers (cotton) under alkaline reducing conditions. They offer a relatively inexpensive way to achieve dark shades like blacks, blues, and browns with good wash fastness but often moderate light fastness.

- Vat Dyes: This class of insoluble dyes requires reduction in an alkaline solution (vatting) to a soluble leuco form, which is then absorbed by the fiber and subsequently oxidized back to the insoluble colored form within the fiber. Vat dyes, often based on anthraquinone or indigoid structures, are known for their excellent wash and light fastness on cellulosic fibers.

- Reactive Dyes: These dyes contain a reactive group that forms a covalent chemical bond with the fiber (primarily cellulosic, but also wool and silk). This strong bond results in excellent wash fastness and bright colors. Different reactive groups (e.g., triazine, vinyl sulfone) react under varying pH conditions.

- Disperse Dyes: These are non-ionic, water-insoluble dyes applied as a fine aqueous dispersion to hydrophobic synthetic fibers like polyester, acetate, and nylon. Dyeing is carried out at elevated temperatures (often under pressure) to allow the dye to penetrate the fiber and dissolve within it. They offer a wide range of colors with generally good light and wash fastness.

- Acid Dyes: These are anionic dyes that are applied to fibers containing basic groups, such as wool, silk, and nylon, in an acidic dyebath. The dye molecules form ionic bonds with the fiber. Acid dyes offer a wide range of bright colors, but their wash fastness varies depending on the dye and fiber.

- Basic Dyes (Cationic Dyes): These are cationic dyes that are attracted to anionic sites on fibers like acrylic, modacrylic, and some modified polyesters. They produce bright, high-intensity colors with generally good light fastness on acrylics but often have poorer wash fastness on other fibers.

- Direct Dyes (Substantive Dyes): These are anionic dyes that have a direct affinity for cellulosic fibers (cotton, viscose) and are applied in a neutral or slightly alkaline dyebath, often with the addition of salt to improve dye uptake. They offer a wide range of colors and are relatively inexpensive but generally have moderate wash and light fastness compared to other classes.

II. Classification of Dyes by Application Method:

The way a dye is applied to a textile fiber is another crucial classification system. This method is largely determined by the chemical nature of both the dye and the fiber. Some key application classes include:

- Direct Dyeing: As mentioned above, this involves applying direct dyes directly to cellulosic fibers in an aqueous bath.

- Vat Dyeing: This specific process involves the reduction and oxidation steps for insoluble vat dyes on cellulosic fibers.

- Reactive Dyeing: This method utilizes reactive dyes that chemically bond with the fiber, primarily cellulose, wool, and silk.

- Disperse Dyeing: This high-temperature process is used for dyeing hydrophobic synthetic fibers with disperse dyes.

- Acid Dyeing: Application of anionic acid dyes to protein and polyamide fibers in an acidic bath.

- Basic Dyeing: Application of cationic basic dyes to acrylic and modified synthetic fibers.

- Mordant Dyeing: This older technique involves using a mordant (a metallic salt) to form a complex with the dye and the fiber, improving wash and light fastness. Many natural dyes require mordants.

- Azoic Dyeing (Ice Dyeing): This method involves forming an insoluble azo dye directly within the fiber by the simultaneous or sequential application of a soluble diazo component and a coupling component. It is primarily used for producing bright shades on cellulosic fibers.

- Pigment Dyeing: Pigments are insoluble coloring agents that are mechanically held onto the surface of the fabric using a binder. This method can be used for almost all fiber types and offers good light fastness but can sometimes affect the fabric’s hand (feel).

The Interrelation of Classifications:

It’s important to note that these two classification systems are interconnected. The chemical structure of a dye often dictates its application method and its affinity for specific fiber types. For example, the non-ionic, water-insoluble nature of disperse dyes makes them suitable for dyeing hydrophobic synthetic fibers under high-temperature conditions. Similarly, the reactive group in reactive dyes enables them to form a covalent bond with hydroxyl groups in cellulose fibers.

Conclusion:

The world of textile dyes is incredibly diverse, with a wide array of chemical structures and application methods tailored to achieve specific colorations on different fiber types. Understanding these fundamental classifications is the first step in comprehending the intricacies of the dyeing process and the properties of dyed textiles. In our subsequent lectures, we will delve deeper into the mechanisms of dyeing and explore the application of specific dye classes to various fibers.

Thank you for joining us today!