Textile Basics: Lecture #9 – Fabric Construction Methods (Part 2: Knitting & Non-Wovens)

Welcome back to our textile series! In our last lecture, we delved into weaving, the intricate interlacing of warp and weft yarns to create fabrics. Today, we’ll expand our understanding of fabric construction by exploring two other major methods: Knitting and Non-Woven Fabrics. These methods offer distinct properties and aesthetics compared to woven textiles.

1. Knitting: The Art of Interlooping

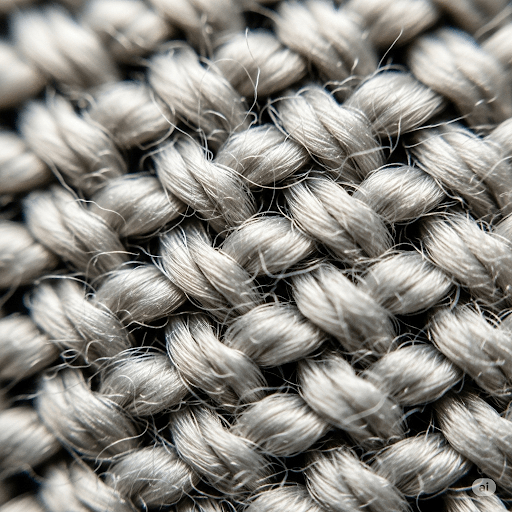

What is Knitting? Knitting is a method of fabric construction where a single yarn (or set of yarns) is interlooped to form a fabric. Unlike weaving, which uses two sets of yarns interlaced at right angles, knitting creates a series of connected loops. This interlooping structure gives knitted fabrics their characteristic stretch and flexibility.

Types of Knitting:

There are two primary types of knitting:

- Weft Knitting:

- Description: Yarn runs horizontally, forming loops across the fabric width. A single yarn feeds all the needles in a single course (row). If a yarn breaks, the loops can easily unravel vertically, leading to a “run” or “ladder.”

- Characteristics:

- High Stretch & Elasticity: Excellent stretch in both length and width.

- Comfortable: Conforms well to the body, making it ideal for activewear and comfortable clothing.

- Good Drape: Soft and fluid drape.

- Less Stable: Can distort or unravel easily if a yarn breaks.

- Wrinkle Resistance: Generally resists wrinkling well.

- Common Weft Knits:

- Jersey Knit (Single Knit): The most common type, smooth on the face, textured on the back. Used for T-shirts, underwear.

- Rib Knit: Alternating knit and purl stitches create vertical ribs, providing excellent stretch and recovery. Used for cuffs, collars, and form-fitting garments.

- Purl Knit: Creates horizontal ridges on both sides. Offers good stretch and bulk. Less common due to slower production.

- Interlock Knit: Two jersey knits locked together, creating a thicker, more stable fabric with a smooth face and back. Used for polos, dresses.

- Warp Knitting:

- Description: Yarn runs vertically, forming loops in a zigzag or diagonal pattern. Multiple yarns are used, with each yarn feeding its own needle. Each loop in a course is formed by a different yarn.

- Characteristics:

- Good Dimensional Stability: More stable than weft knits, less prone to runs or ladders.

- Less Stretch: Offers less stretch than weft knits, primarily in the width.

- Resistant to Runs: Because each loop is independently formed by a separate yarn.

- Less Drape: Can be stiffer than weft knits.

- Common Warp Knits:

- Tricot: Fine, plain knit with a zigzag pattern. Used for lingerie, swimwear linings, activewear.

- Raschel: More complex and open structures, can create lace, netting, and power mesh. Used for activewear, industrial textiles.

Sustainability Considerations of Knitting:

- Reduced Waste: Knitting (especially computerized flatbed knitting) can be more efficient than cut-and-sew for some garments, leading to less fabric waste. “WholeGarment” or “Seamless” knitting can produce entire items with virtually no waste.

- Energy Use: Similar to weaving, energy consumption during production is a factor.

- Yarn Choice: The sustainability of the chosen fibers and yarns remains paramount.

2. Non-Woven Fabrics: Bonded Fibers

What are Non-Woven Fabrics? Non-woven fabrics are textile-like materials made directly from fibers, without the traditional processes of spinning yarn or weaving/knitting. Instead, fibers are laid in a random or oriented web and then bonded together through mechanical, thermal, or chemical means.

Key Characteristics:

- No Yarn Required: Eliminates spinning and weaving/knitting steps, which can make production faster and cheaper.

- Variable Properties: Properties vary widely depending on the fibers used and the bonding method. They can be soft and flexible or stiff and rigid.

- Limited Drape & Strength: Generally have less drape and tear strength compared to woven or knitted fabrics, but can be engineered for specific strength in certain directions.

- Disposable or Durable: Can be designed for single-use (e.g., medical masks) or long-term durability (e.g., interlinings).

Common Non-Woven Production Methods:

- Mechanical Bonding (Needle Punching): Fibers are entangled using barbed needles, creating a felt-like material. (e.g., carpets, interlinings).

- Thermal Bonding: Fibers (often thermoplastic like polypropylene or polyester) are heated to their melting point and fused together at points of contact. (e.g., hygiene products, geotextiles).

- Chemical Bonding (Binders): A chemical adhesive (binder) is applied to bond the fibers together. (e.g., disposable wipes, medical gowns).

- Spunbond: Fibers are extruded (spun) directly onto a conveyor belt in a web and then bonded (often thermally), forming strong, lightweight fabrics. (e.g., disposable medical garments, protective covers).

- Meltblown: Polymer is extruded through tiny nozzles into high-velocity air, creating extremely fine fibers that are collected on a screen and form a self-bonded web. Known for excellent filtration. (e.g., face mask filters, insulation).

Common Uses:

- Disposable Products: Diapers, wipes, sanitary napkins, surgical gowns, face masks.

- Medical: Dressings, filters, sterilization wraps.

- Industrial: Geotextiles (for civil engineering), insulation, filtration media, automotive interiors.

- Apparel (Limited): Interlinings, insulation.

Sustainability Considerations of Non-Wovens:

- Resource Efficiency: Can be more resource-efficient in terms of water and energy during production compared to traditional textile processes, as they bypass spinning and weaving/knitting.

- Raw Material: Often use synthetic fibers (polypropylene, polyester) which share the sustainability concerns of petrochemical reliance and non-biodegradability.

- Disposability: A significant sustainability challenge. Many non-wovens are designed for single-use, leading to large volumes of landfill waste, especially if made from non-biodegradable synthetics.

- Recycling Challenges: Difficult to recycle due to their blended fiber content and bonding methods.

Comparing Fabric Structures:

| Feature | Woven Fabrics | Knitted Fabrics | Non-Woven Fabrics |

|---|---|---|---|

| Structure | Interlacing two sets of yarns (warp & weft) | Interlooping a single (weft) or multiple (warp) yarn(s) | Fibers bonded directly, no yarn stage |

| Stretch | Minimal (unless made with elastic yarns) | High (especially weft knits) | Minimal (unless engineered), variable |

| Drape | Variable (crisp to fluid) | Soft, fluid | Stiff to soft, generally less drape |

| Stability | High, dimensionally stable | Lower (weft knits can run/distort) | Variable, can be engineered for stability |

| Breathability | Variable | Good | Variable, can be engineered |

| Uses | Apparel, home furnishings, industrial | Apparel (especially stretch), hosiery | Disposable, medical, industrial, interlinings |

Export to Sheets

Understanding these diverse fabric construction methods is essential for appreciating the variety of textiles available and selecting the right material for any given purpose.

In our next lecture, Lecture #10, we will begin to explore Textile Finishing Processes, learning how fabrics are treated to enhance their properties, appearance, and performance after construction.