Textile Basics: Lecture #6 – Man-Made Synthetic Fibers (Part 2: Acrylic & Spandex/Elastane)

Welcome back to our textile journey! We’ve already covered the workhorses of synthetic fibers, polyester and nylon. Today, we’ll continue our exploration of man-made synthetics by looking at two more specialized, yet equally important, fibers: Acrylic and Spandex (also known as Elastane). These fibers bring unique properties to textiles, offering warmth, softness, and incredible stretch.

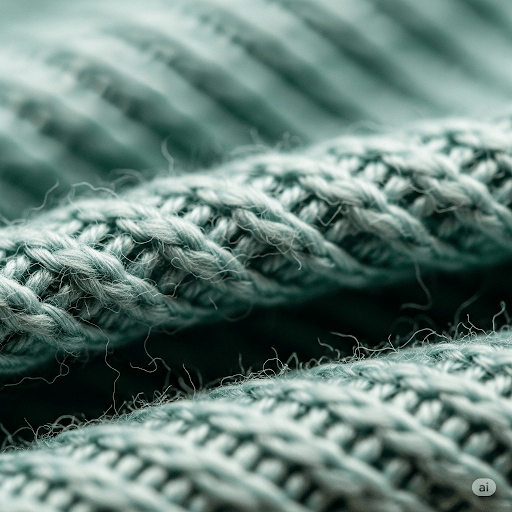

1. Acrylic: The “Wool Substitute”

Origin: Acrylic fibers are synthetic polymers made from at least 85% acrylonitrile. They were first developed in the mid-20th century as an alternative to wool, offering a similar soft hand and bulk but with greater durability and easier care.

Key Properties:

- Softness & Warmth: Acrylic is known for its soft, wool-like feel and excellent insulating properties, making it very warm for its weight. It’s often used in sweaters and blankets where a cozy feel is desired.

- Lightweight: Despite its warmth, acrylic is a lightweight fiber.

- Resilience & Wrinkle Resistance: It has good resilience, meaning it holds its shape well and resists wrinkling.

- Resistance to Sunlight & Chemicals: Excellent resistance to sunlight (UV degradation), making it suitable for outdoor applications. It also resists chemicals, moths, and mildew.

- Colorfastness: Takes and holds dye very well, resulting in vibrant, long-lasting colors.

- Hydrophobic: Absorbs very little moisture, making it quick-drying.

- Pilling: A common drawback is its tendency to pill (form small balls of fiber on the surface) with wear, especially lower-quality acrylics.

Common Uses:

- Apparel: Sweaters, knitwear, socks, hats, gloves, blankets, babywear, tracksuits.

- Home Furnishings: Upholstery, carpets, blankets.

- Outdoor/Industrial: Awnings, outdoor furniture fabrics, boat covers due to its UV resistance.

Sustainability Considerations of Acrylic:

- Fossil Fuel Dependence: Like polyester and nylon, acrylic is derived from petrochemicals, a non-renewable resource, contributing to greenhouse gas emissions during production.

- Energy Intensive: Its manufacturing process is energy-intensive.

- Non-Biodegradable: Acrylic is not biodegradable and persists in the environment for centuries.

- Microplastic Shedding: Acrylic garments are significant contributors to microplastic pollution, shedding tiny plastic fibers during washing that can enter waterways.

- Recycling Challenges: It’s more challenging to recycle acrylic into new fibers compared to polyester, often requiring chemical processes or being downcycled.

2. Spandex (Elastane): The Stretch Powerhouse

Origin: Spandex, known as Elastane in Europe and other parts of the world, is a synthetic fiber renowned for its exceptional elasticity. It was invented by DuPont in the late 1950s and revolutionized comfortable activewear and form-fitting garments. It’s a segmented polyurethane polymer.

Key Properties:

- Exceptional Elasticity & Recovery: Its defining characteristic. Spandex can stretch significantly (up to 5-8 times its original length) and then fully recover to its original shape. This provides unparalleled comfort and fit.

- Strength & Durability: Despite its elasticity, it is a strong and durable fiber.

- Lightweight: It’s a very lightweight fiber, often blended in small percentages with other fibers.

- Abrasion Resistance: Good resistance to abrasion.

- Resistance to Degradation: Resists degradation from body oils, perspiration, detergents, and chlorine, making it ideal for swimwear and activewear.

- Heat Sensitivity: Like other synthetics, it’s heat sensitive and can be damaged by high temperatures.

Common Uses (almost always in blends):

- Apparel: Activewear, swimwear, hosiery, underwear, denim (for stretch comfort), leggings, athletic shorts, form-fitting garments, socks.

- Medical: Compression garments, bandages.

- Home Furnishings: Upholstery (for stretch fit).

Sustainability Considerations of Spandex/Elastane:

- Fossil Fuel Dependence: Derived from petrochemicals.

- Non-Biodegradable: Like other synthetics, it is not biodegradable.

- Recycling Difficulty: Its elastic nature makes it extremely difficult to recycle, especially when blended with other fibers, which is almost always the case. This means garments containing even a small percentage of spandex often end up in landfills.

- Chemical Use: The production process involves hazardous chemicals, though efforts are made to manage these responsibly.

- Longevity vs. Disposal: While its durability contributes to longer garment life, its non-recyclability poses an end-of-life challenge.

Both acrylic and spandex/elastane offer specific performance benefits that are hard to achieve with natural fibers alone. However, their reliance on fossil fuels and end-of-life challenges (non-biodegradability and recycling difficulties) are significant sustainability concerns that drive ongoing research into more eco-friendly alternatives.

With this, we’ve completed our overview of the major fiber types. Our next lecture will shift gears and begin to explore how these fibers are transformed into Yarns, the next critical step in textile production.