Specific Challenges & Solutions for Dyeing Process Water Quality: Lecture 6

Overall Goal: To understand how the specific quality of treated and reused water impacts different textile dyeing and finishing processes, and the final conditioning steps required to meet stringent industry standards.

6.1. Recapping Treated Water Quality & Initial Reuse Suitability

- Review of Previous Stages: Briefly revisit the quality of water typically achieved after primary, secondary, and advanced (tertiary) treatment (e.g., very low BOD/COD, low TSS, significant color reduction, low turbidity from RO).

- The “Good Enough” vs. “Optimal” Gap: Discuss why even highly treated water might not be directly optimal for all sensitive textile processes without further fine-tuning.

- Textile Industry’s Unique Demands: Emphasize that unlike general industrial processes, textile wet processing has very specific requirements due to the chemical interactions with dyes and fibers.

6.2. Critical Water Quality Parameters for Textile Processing

We’ll delve into specific parameters and their detrimental effects if not properly controlled for reuse:

- Conductivity / Total Dissolved Solids (TDS) / Salinity:

- Impact: High salinity can interfere with dye solubility, uptake efficiency (especially for reactive dyes, leading to weaker shades or non-uniform dyeing), salt build-up in machinery, and increased energy consumption for heating.

- Importance for Reuse: RO is key to reducing this, but residual levels still matter.

- Hardness (Calcium and Magnesium Ions):

- Impact: Forms insoluble precipitates with dyes, soaps, and scouring agents, leading to dull colors, spots on fabrics, excessive consumption of chemicals, and scaling in pipes/machinery (boilers, heat exchangers).

- Importance for Reuse: Critical for almost all textile wet processes.

- Residual Oxidants (e.g., Chlorine, Peroxide):

- Impact: Even trace amounts can react with certain dyes, causing shade changes, color dullness, or even fabric damage, especially in sensitive dyeing processes.

- Sources: Disinfection from the treatment plant, or residual from bleaching processes if internal reuse streams are mixed.

- pH:

- Impact: Dyeing and finishing processes are highly pH-sensitive. Incorrect pH can alter dye ionization, lead to poor dye fixation, damage fibers, or reduce efficiency of auxiliary chemicals.

- Importance for Reuse: While usually adjusted in primary treatment, final pH adjustment right before reuse is often necessary.

- Heavy Metals:

- Impact: Can act as mordants causing off-shades or dullness, affect dye fastness, or be absorbed by the fiber (environmental/health concern).

- Sources: From certain older dyes, mordants, or impurities in process chemicals.

- Silica:

- Impact: Can cause scaling, especially in boilers and heat exchangers, leading to reduced efficiency and increased maintenance.

- Importance for Reuse: Relevant for boiler feed water.

- Trace Organics / Residual Color:

- Impact: Even slight residual color can affect light shades, while certain trace organics might impact dye uptake or fastness.

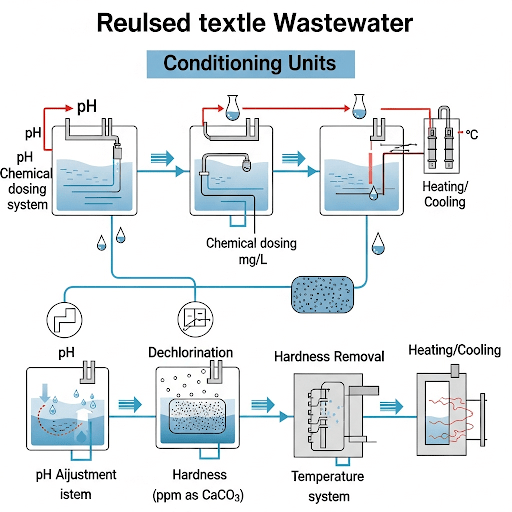

6.3. Post-Treatment Polishing & Conditioning for Specific Reuse Applications

This section focuses on the final, targeted adjustments to the treated water.

- Final pH Adjustment: Using precise dosing systems to bring the water to the exact pH required for the specific dyeing or finishing bath.

- Dechlorination / Oxidant Removal:

- Methods: Using activated carbon filters (granular activated carbon – GAC) or chemical dosing (e.g., sodium bisulfite, sulfur dioxide) to neutralize residual chlorine or other oxidants.

- Importance: Essential for protecting sensitive dyes and preventing fabric damage.

- Hardness Removal / Softening:

- Methods: Ion Exchange Resins (most common for textile reuse) where calcium and magnesium ions are exchanged for sodium ions. Can also include chemical softening (lime-soda ash process for larger scale).

- Importance: Crucial for preventing scaling and ensuring optimal dye performance.

- Temperature Adjustment:

- Importance: Reused water might be at ambient temperature, but many dyeing processes require specific hot or warm water. Heat exchangers are used to adjust temperature, often utilizing heat recovered from other hot wastewater streams.

- Energy Recovery: Emphasize the energy savings associated with heat recovery.

- UV Sterilization (Optional):

- Purpose: An additional layer of disinfection to ensure the water is free of microbial contamination before sensitive applications, especially if stored.

6.4. Case Studies & Best Practices for Textile Reuse

- Real-World Examples: Present examples of textile mills that successfully implement water reuse, detailing the specific challenges they faced and the conditioning steps they apply to their treated water for different processes (e.g., one quality for washing, a higher quality for dyeing, and an even higher quality for boiler feed).

- Monitoring & Control: Reinforce the importance of continuous, online monitoring of critical water quality parameters right before reuse points to ensure consistent quality.

- Risk Assessment for Reuse: Discuss identifying potential contaminants in the reused water and managing risks to product quality.

By the end of this lecture, students will appreciate that “clean water” from a wastewater treatment plant isn’t a one-size-fits-all solution, and that precise conditioning is vital to truly close the water loop in textile manufacturing.