Sludge Management & System Integration for Reuse: Lecture 5

Overall Goal: To understand the challenges and strategies for managing the solid and concentrated liquid byproducts of textile wastewater treatment, and to synthesize how all treatment stages are integrated into an efficient, cost-effective system for water reuse.

5.1. Sludge Management: The Other Side of Treatment

- Sources of Sludge: Sludge isn’t just one thing. We’ll identify where it comes from in our treatment train:

- Primary Sludge: From coagulation, flocculation, and sedimentation (contains suspended solids, dyes, chemicals).

- Secondary (Biological) Sludge: Excess biomass from activated sludge or MBRs (contains microorganisms and absorbed organic matter).

- Chemical Sludge: From specific chemical precipitation steps, or from membrane cleaning.

- Membrane Concentrates: The highly saline and pollutant-rich reject stream from Nanofiltration (NF) and especially Reverse Osmosis (RO) — often a liquid waste, but sometimes treated to produce solid salt.

- Characterization: Sludge is typically high in water content, can contain residual dyes, heavy metals (if present in original dyes/chemicals), and various organic/inorganic compounds. This makes handling and disposal challenging.

- Treatment Technologies for Sludge:

- Thickening: Reducing water content to decrease volume. Methods include gravity thickeners (like small clarifiers) or Dissolved Air Flotation (DAF) for lighter sludges.

- Dewatering: Further reducing water content to make sludge more solid and handleable. Common methods include belt filter presses, plate-and-frame filter presses, and centrifuges.

- Stabilization: Processes to reduce pathogens, odors, and the putrescibility of organic sludge. Anaerobic digestion (producing biogas) or lime stabilization are common.

- Disposal & Valorization:

- Landfilling: The simplest, but increasingly expensive and regulated option due to environmental concerns.

- Incineration: Burning sludge, which can reduce volume and sometimes recover energy, but requires air pollution control.

- Co-processing: Using dewatered sludge as a fuel source or raw material in other industrial processes (e.g., cement kilns).

- Beneficial Reuse: Highly dependent on sludge composition. Can potentially be used as soil conditioner or compost, but strict regulations apply, especially for textile sludge due to potential chemical contaminants.

5.2. System Integration & Optimization for Reuse

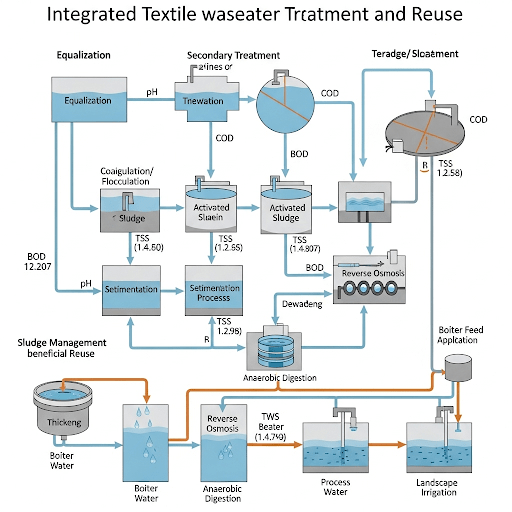

- Process Flow Diagrams (PFDs): We’ll review and analyze typical comprehensive process flow diagrams for textile wastewater treatment plants designed for reuse. This involves connecting all the stages we’ve learned about (Equalization → Primary Treatment → Secondary Treatment → Tertiary/Advanced Treatment).

- Energy Consumption: A major operational cost. We’ll discuss how different technologies contribute to energy demand (e.g., aeration in activated sludge, pumps for membranes, high-pressure pumps for RO). Strategies for energy optimization and heat recovery (e.g., from hot wastewater) will be explored.

- Chemical Consumption: Managing the input of chemicals (coagulants, pH adjusters, anti-scalants for membranes, disinfectants, cleaning agents) and their associated costs and storage.

- Automation & Control: The importance of real-time monitoring (e.g., pH, ORP, Dissolved Oxygen, conductivity, turbidity, color) and automated control systems to ensure consistent treated water quality and efficient plant operation.

- Economics of Water Reuse: A critical section covering the cost-benefit analysis. This includes:

- Capital Expenditure (CapEx): Cost of building the plant.

- Operational Expenditure (OpEx): Recurring costs (energy, chemicals, labor, maintenance, sludge disposal).

- Savings: Reduced freshwater purchase costs, lower effluent discharge fees, and potential for recovered resources (e.g., heat, reusable chemicals, biogas).

- Payback Period: How long it takes for the savings to offset the investment.

5.3. Case Studies & Emerging Technologies

- Real-World Examples: We’ll examine successful case studies of textile factories in Pakistan and globally that have implemented advanced wastewater treatment for reuse, highlighting their chosen technologies, challenges, and benefits.

- Novel Technologies: Briefly introduce cutting-edge or next-generation technologies that are still in research or early adoption phases:

- Electrochemical Oxidation: Using electricity to generate powerful oxidants.

- Supercritical Water Oxidation (SCWO): For highly concentrated, toxic waste streams.

- Hybrid Systems: Combining multiple technologies in innovative ways to achieve specific goals.

- Future Trends: Discuss the shift towards Zero Liquid Discharge (ZLD) in the textile industry and the broader concept of water circularity and resource recovery.

5.4. Environmental & Economic Considerations of Brine Management (RO Concentrate)

- The Brine Challenge: The concentrated reject stream from RO (and sometimes NF) is a major environmental and economic hurdle. It’s high in salts and residual pollutants.

- Disposal Options:

- Deep Well Injection: Pumping into deep geological formations (limited applicability, environmental concerns).

- Solar Evaporation Ponds: Simple, but requires large land area and specific climate conditions.

- Zero Liquid Discharge (ZLD) Technologies: Processes designed to recover all water, leaving only solid waste. This often involves:

- Evaporators: To concentrate the brine further.

- Crystallizers: To precipitate salts as solids.

- Cost Implications of ZLD: Often very high energy and capital costs, but driven by strict regulations or extreme water scarcity.

By the end of this lecture, you’ll have a holistic view of the entire textile wastewater treatment and reuse ecosystem, understanding not just the individual technologies but also their crucial integration and the broader economic and environmental considerations that drive sustainable practices.