Nanotechnology & It’s Applications in Textiles

Nanotechnology is an exciting and rapidly evolving field that involves understanding, manipulating, and controlling matter at the nanoscale – typically between 1 to 100 nanometers (nm). To give you a sense of just how tiny that is, a human hair is about 80,000 to 100,000 nanometers thick!

At this incredibly small scale, materials often exhibit unique physical, chemical, and biological properties that are different from their larger, macroscopic forms. For example, a material might become stronger, more reactive, better at conducting electricity, or even change color when it’s manipulated at the nanoscale. This is due to factors like increased surface area-to-volume ratio and quantum effects.

Nanotechnology isn’t a single discipline; it’s an interdisciplinary field that brings together chemistry, physics, materials science, biology, and engineering to design and create novel structures, devices, and systems.

Applications of Nanotechnology in Textiles

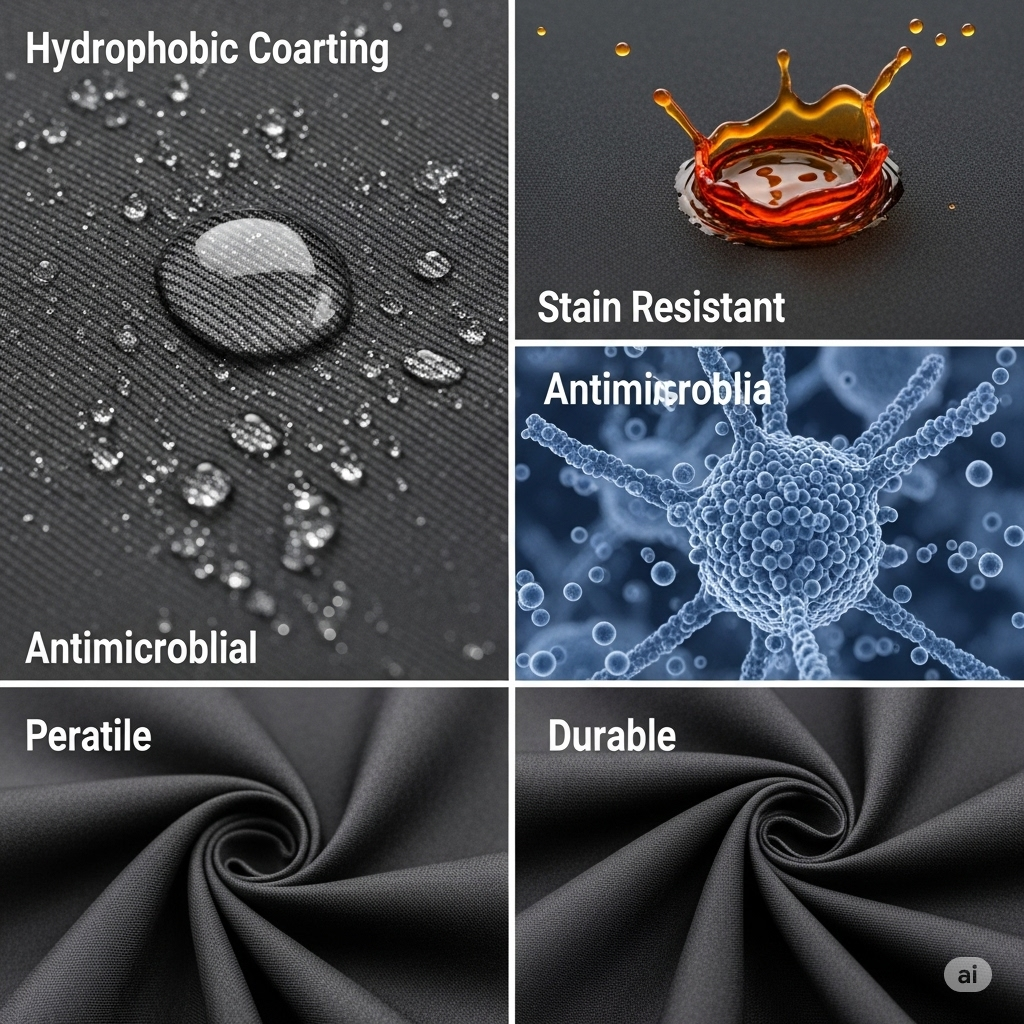

The textile industry has been significantly transformed by nanotechnology, moving beyond basic fabric functions to create “smart” and “functional” textiles. By integrating nanoparticles or nanostructures into fibers, yarns, or applying them as coatings, fabrics can gain revolutionary new properties.

Here are some key applications of nanotechnology in textiles:

- Water and Stain Repellency (Hydrophobic/Oleophobic Fabrics):

- How it works: Nanoparticles (like silica, titanium dioxide, or nano-whiskers made of hydrocarbons) are applied to the fabric surface. These create a rough, textured, or highly repellent layer at the nanoscale, mimicking the “Lotus effect” found in nature. This prevents water, oils, and other liquids from penetrating the fibers, causing them to bead up and roll off.

- Benefits: Easier cleaning, reduced need for washing, extended garment life, ideal for outdoor wear, uniforms, and upholstery.

- Antimicrobial and Anti-Odor Properties:

- How it works: Silver nanoparticles (AgNPs) are particularly effective, along with zinc oxide (ZnO) and titanium dioxide (TiO2) nanoparticles. These nanoparticles release ions that inhibit the growth of bacteria, fungi, and other microbes that cause odors and degradation.

- Benefits: Odor-free clothing (especially for socks, sportswear, undergarments), improved hygiene for medical textiles (hospital linens, bandages), and enhanced freshness.

- UV Protection:

- How it works: Nanoparticles of titanium dioxide (TiO2) and zinc oxide (ZnO) are incorporated into the fabric. These act as efficient UV blockers, absorbing or scattering harmful ultraviolet radiation.

- Benefits: Enhanced protection against sun damage for skin, extended lifespan of fabrics (as UV light can degrade dyes and fibers), ideal for outdoor apparel.

- Wrinkle Resistance:

- How it works: Nano-engineered cross-linking agents are applied to cotton fabrics during finishing. These agents help the fibers retain their shape and prevent creasing.

- Benefits: Fabrics stay smoother for longer, reducing the need for ironing and making garments easier to care for.

- Enhanced Durability and Strength:

- How it works: Nanoparticles like carbon nanotubes (CNTs), alumina (Al2O3), or silica (SiO2) can be embedded into fibers, strengthening them at a molecular level. This increases tensile strength, abrasion resistance, and overall resilience.

- Benefits: Longer-lasting garments, improved performance for protective clothing, military uniforms, and activewear.

- Self-Cleaning Fabrics:

- How it works: Often using titanium dioxide (TiO2) nanoparticles, these fabrics employ a photocatalytic effect. When exposed to sunlight, the nanoparticles break down organic dirt and pollutants, which are then easily washed away by rain or a simple rinse.

- Benefits: Reduced washing frequency, less water and detergent consumption, minimal effort to keep clothes clean.

- Anti-Static Properties:

- How it works: Incorporating conductive nanomaterials like carbon nanotubes or conductive polymers helps to dissipate static electricity.

- Benefits: Prevents clinging, lint attraction, and uncomfortable static shocks, especially in synthetic fabrics.

- Thermal Regulation (Smart Textiles):

- How it works: Phase Change Materials (PCMs) in nano-encapsulated forms can be integrated into fabrics. These materials absorb or release heat in response to changes in body temperature or ambient temperature, providing active cooling or warming.

- Benefits: Enhanced comfort for sportswear, outdoor gear, and medical textiles.

- Conductive and Smart Textiles:

- How it works: Nanoparticles of metals (like silver, copper, gold) or carbon nanotubes can make fabrics electrically conductive. This allows for the integration of sensors, batteries, and electronic components directly into clothing.

- Benefits: Wearable electronics for health monitoring (heart rate, temperature), interactive clothing, smart uniforms for military or industrial use.

Nanotechnology is continuously pushing the boundaries of what textiles can do, moving them from passive coverings to active, functional materials that enhance comfort, safety, and convenience.