Lecture 8: The Doubling/Twisting Machine – Creating Stronger, More Uniform Plied Yarns

So far, we’ve focused on the creation of single yarns – a single strand of twisted fibers. However, for many textile applications, a single yarn might not provide sufficient strength, evenness, or specific aesthetic properties. This is where the Doubling/Twisting Machine comes into play, creating plied yarns (also known as folded yarns or doubled yarns).

I. Introduction: Beyond the Single Strand – The Power of Ply

The Doubling/Twisting Machine takes two or more single yarns and twists them together to form a stronger, more uniform, and often more lustrous plied yarn. This process enhances various yarn characteristics, making it suitable for a wider range of demanding applications.

II. Objectives of the Doubling/Twisting Process

The main objectives of combining and twisting multiple single yarns are:

- Increased Strength: Combining multiple single yarns significantly increases the overall strength of the plied yarn. If one single yarn has a weak spot, the other plies can compensate.

- Improved Evenness and Uniformity: By averaging out irregularities present in individual single yarns, the plied yarn exhibits better evenness, fewer thick and thin places, and reduced neppiness.

- Reduced Hairiness: Twisting multiple strands together often results in a smoother yarn surface with fewer protruding fibers (less hairiness).

- Enhanced Abrasion Resistance: The compact, twisted structure of plied yarn makes it more resistant to abrasion, increasing its durability.

- Improved Luster and Appearance: Plied yarns often have a more uniform and sometimes a slightly more lustrous appearance due to better fiber alignment and reduced hairiness.

- Special Effects: Can be used to create novelty yarns by twisting different colored yarns, different fiber types, or yarns with varying twist levels.

- Increased Diameter/Count Versatility: Allows for the creation of thicker yarns with enhanced properties, without needing to spin a very coarse single yarn.

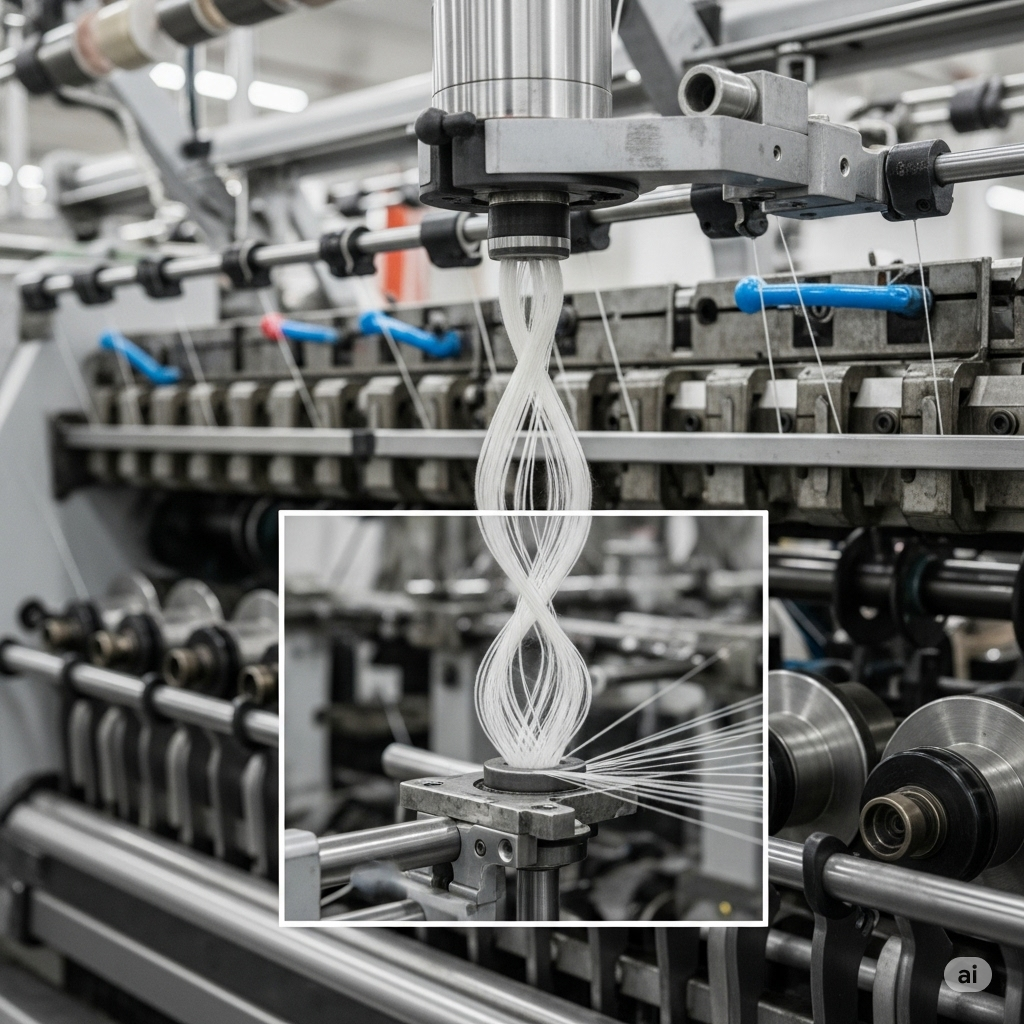

III. Principle of Operation: Combining and Twisting

The Doubling/Twisting machine takes yarn from multiple cones (usually 2, 3, or 4) and twists them together using a similar spindle-and-ring-traveller mechanism as the ring frame, or sometimes a two-for-one (TFO) twister.

- Yarn Feeding: Two or more individual yarn cones (wound in the previous winding stage) are mounted in the creel for each spindle position. The yarns are fed simultaneously from these cones.

- Yarn Guiding and Tensioning: The individual yarns are guided through tensioning devices to ensure uniform tension before they are combined.

- Combining Point: The individual yarns converge and are guided together to form a single, untwisted composite strand.

- Twisting Mechanism:

- Ring Twister (Conventional): Similar to a ring frame, the combined strand passes through a lappet guide, then through the traveller on a ring, and is wound onto a bobbin on a rapidly rotating spindle. Each revolution of the traveller inserts one turn of twist into the combined yarn.

- Two-for-One (TFO) Twister (Modern & Prevalent): This is the more common and efficient method for doubling/twisting. In a TFO twister, two twists are inserted for every revolution of the spindle.

- The yarn unwinds from a package mounted inside a stationary pot.

- The yarn then passes through a rotating disc or flyer, which imparts the first twist as the yarn travels from the package eye to the spindle top.

- The yarn then travels down the hollow spindle and back up to the delivery rollers, forming a balloon. The rotation of the entire spindle (which includes the twisting element) imparts the second twist.

- The twisted yarn then passes through delivery rollers and is wound onto a take-up package (cone or cheese).

- TFO twisters are highly productive and produce balanced, knot-free twisted yarns.

- Winding onto Take-up Package: The newly formed plied yarn is wound onto a final package (cone or cheese) for further processing or dispatch.

IV. Key Features of Modern Doubling/Twisting Machines

- Two-for-One (TFO) Technology: Predominantly used due to its higher productivity, lower energy consumption per unit of twist, and production of knot-free, more uniform plied yarns.

- Individual Spindle Control: Each twisting position operates independently, allowing for continuous operation.

- Precise Tension Control: Electronic or mechanical tensioners ensure consistent yarn tension throughout the process.

- Automatic Stop Motions: Machines stop automatically upon yarn breakage or package exhaustion, minimizing waste and facilitating operator intervention.

- Digital Controls: Touchscreen interfaces for precise setting of twist levels (turns per meter/inch), winding speeds, and package density.

- Energy Efficiency: Optimized motors and drives for reduced power consumption, particularly in TFO twisters.

- Balloon Control: Devices to control the yarn balloon during twisting, preventing tangles and ensuring smooth operation.

V. Advantages of Plied Yarns (Produced by Doubling/Twisting)

- Enhanced Yarn Properties: Superior strength, improved evenness, reduced hairiness, and better abrasion resistance compared to single yarns of comparable count.

- Improved Fabric Quality: Fabrics made from plied yarns are generally stronger, more durable, have a better appearance, and often a softer hand-feel.

- Better Downstream Performance: Plied yarns experience fewer breakages in weaving and knitting, leading to higher machine efficiencies and reduced production losses.

- Versatility: Can be used to create a wide range of products, from fine apparel fabrics to industrial textiles and carpets.

- Value Addition: Plying adds significant value to the yarn, allowing it to be used in premium applications.

VI. Limitations and Considerations

- Added Cost: The doubling/twisting process is an additional step in yarn production, adding to the overall manufacturing cost (capital investment, energy, labor).

- Energy Consumption: Twisting machines, especially ring twisters, can be energy-intensive. TFO twisters are more efficient but still consume substantial power.

- Floor Space: Requires dedicated floor space within the spinning mill.

- Noise: Can be a noisy operation, requiring proper acoustic considerations in factory design.

- Skill Requirements: Operators need to be skilled in setting twist levels and monitoring yarn quality.

VII. Relevance to Lahore, Pakistan

The Doubling/Twisting Machine is a vital component for many spinning mills in Lahore, especially those producing yarns for high-quality fabrics and specialized applications:

- Meeting Export Demands: A significant portion of Pakistan’s textile exports, particularly high-end apparel, home textiles, and specialized industrial fabrics, require plied yarns for superior performance and aesthetics.

- Value-Added Products: Investment in doubling/twisting capabilities allows Lahore’s mills to produce higher-value yarns, improving profitability and market competitiveness.

- Technological Adoption: Modern mills are actively investing in advanced TFO twisters from global manufacturers (e.g., Saurer Volkmann, Murata, Savio) to achieve optimal efficiency and quality.

- Diversification: Enables mills to diversify their product portfolio beyond single yarns, catering to a broader range of customer needs.

- Skill Enhancement: The operation and maintenance of these sophisticated machines contribute to the continuous upskilling of the textile workforce in the region.

In conclusion, the Doubling/Twisting Machine plays a crucial role in elevating yarn quality from a single strand to a multi-plied structure. By imparting precise twist, it significantly enhances yarn strength, evenness, and appearance, making plied yarns the preferred choice for demanding textile applications and a hallmark of quality production in modern spinning mills.

This concludes our lecture on the Doubling/Twisting Machine. In our final lecture of the series, we will briefly cover other important post-spinning processes like Reeling, Bundling, and Packing, and then summarize the future trends and sustainable directions for the spinning industry as a whole.