Lecture 3: The Draw Frame – Perfecting Fiber Parallelization and Sliver Uniformity

In our previous lecture, we saw how the Carding Machine effectively individualizes fibers and forms them into a continuous sliver. While this sliver is significantly cleaner and more uniform than the blow room tufts, the fibers within it are still not perfectly parallel, and there can be variations in its weight per unit length. This is where the Draw Frame comes into play.

I. Introduction: Refining the Sliver for Optimal Yarn Quality

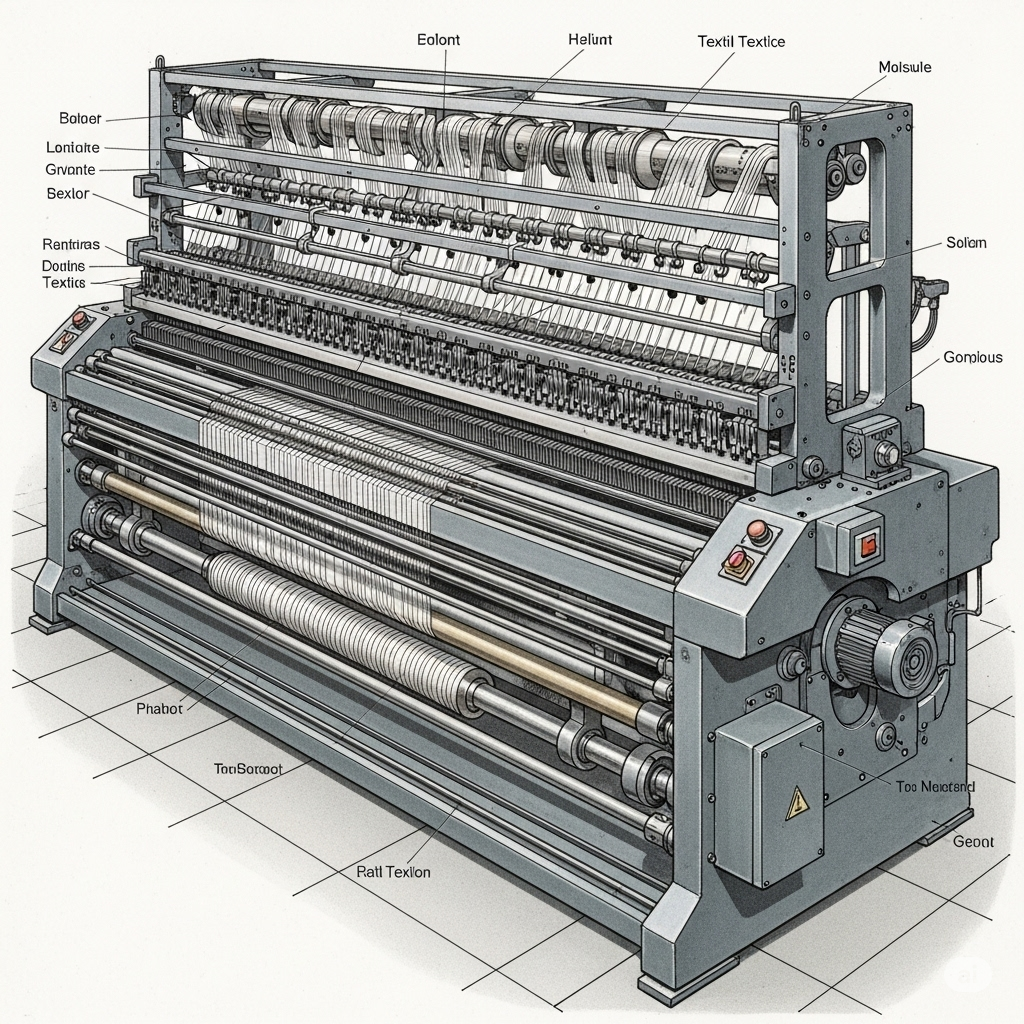

The Draw Frame is a critical machine in the spinning preparatory process that aims to further improve the quality of the sliver by parallelizing the fibers and, most importantly, achieving excellent sliver uniformity or evenness. It does this through a process called “doubling” and “drafting.” Without proper drawing, the yarn produced would be irregular, weak, and hairy.

II. Objectives of the Drawing Process

The main objectives of the Draw Frame are:

- Parallelization of Fibers: To straighten and align the fibers within the sliver so they are as parallel as possible to the sliver axis. This is crucial for optimal yarn strength and evenness.

- Equalization/Uniformity (Evenness): To significantly improve the weight per unit length of the sliver (its evenness). This is achieved through the principle of doubling and drafting.

- Blending: To achieve a more intimate and thorough blend of fibers from different sliver cans. This further homogenizes the material, compensating for any residual variations.

- Dust Removal (Minor): While not its primary function, some fine dust can be dislodged and removed during the drafting process.

III. Principle of Operation: Doubling and Drafting

The Draw Frame operates on two core principles:

- Doubling: Multiple slivers (typically 6 or 8 from the carding machine) are fed side-by-side into the draw frame. These slivers are “doubled” together, meaning they are combined into a single, composite sliver. This averaging effect immediately improves the uniformity and reduces the variations present in individual card slivers. If one sliver is slightly thin, others might be thicker, averaging out the irregularities.

- Drafting: Immediately after doubling, the combined sliver passes through a drafting system. This system consists of multiple pairs of rollers, where each subsequent pair rotates faster than the preceding one. As the sliver passes through these rollers, it is stretched and thinned out. The ratio of the surface speed of the front roller to the back roller is the drafting ratio. Crucially, the total draft applied is designed to be approximately equal to the number of slivers doubled. For instance, if 8 slivers are fed, a draft of around 8 is applied, meaning the output sliver has roughly the same weight per unit length as a single input sliver, but with greatly improved uniformity and fiber parallelization.

Process Flow:

- Creel Section: Multiple sliver cans from the carding (or comber) are placed here.

- Doubling: The ends from these cans are guided and combined.

- Drafting Zone: The combined sliver passes through a series of drafting rollers (typically 3 over 3 or 4 over 4 roller arrangements, with pressure rollers) that accelerate the fibers and parallelize them.

- Coiler Section: The final, drawn sliver is then delivered by a coiler mechanism into a new, uniform sliver can.

IV. Key Features of Modern Draw Frames

- Auto-Levelling Systems: This is arguably the most critical feature. Modern draw frames are equipped with sophisticated auto-levellers that continuously measure the thickness/mass of the incoming sliver. If a thick spot is detected, the machine automatically and instantaneously increases the draft in that section to compensate, ensuring a highly uniform output sliver. If a thin spot is detected, the draft is reduced. This dynamic adjustment is key to achieving excellent evenness.

- High Delivery Speed: Modern draw frames can deliver sliver at very high speeds (e.g., 800-1100 meters per minute or even more), maximizing productivity.

- Short Fiber Hooks Removal: The drafting action helps to straighten out fiber hooks (bent ends of fibers) that are prevalent after carding, further improving fiber parallelization.

- Advanced Drafting Systems: Designed for precise control over fiber movement during drafting, minimizing fiber damage and optimizing parallelization.

- Efficient Dust and Waste Extraction: Integrated suction systems to remove any loose fibers or dust generated during drafting.

- Online Quality Monitoring: Sensors provide real-time data on sliver evenness, neps, and thick/thin places, allowing for immediate adjustments and quality control.

- User-Friendly Interfaces: Touchscreen controls and diagnostic tools simplify operation and troubleshooting.

V. Advantages of the Draw Frame

- Exceptional Sliver Evenness: The combination of doubling and auto-levelling produces a sliver with outstanding uniformity, leading to more even and consistent yarn.

- Superior Fiber Parallelization: Crucial for achieving higher yarn strength and reducing hairiness.

- Improved Blending: Thorough mixing of fibers, enhancing yarn homogeneity.

- Reduced Yarn Defects: A well-drawn sliver drastically reduces thick and thin places, neps, and breaks in the final yarn.

- Higher Downstream Efficiency: Reduces end breakages at the speed frame and ring frame, leading to higher machine efficiency and productivity.

VI. Limitations and Considerations

- Doubling Limit: While doubling is beneficial, too many doublings without sufficient drafting can lead to poor fiber control and increased neps.

- Drafting Limits: Excessive drafting can cause fiber damage or uncontrolled fiber movement, leading to uneven sliver and broken fibers.

- Drafting Zone Settings: Proper setting of roller nip pressures, roller gauge (distance between rollers), and drafting ratios is critical and requires skilled operators.

- Sliver Breakages: Can occur due to poor input sliver quality or incorrect machine settings, leading to production stops.

- Energy Consumption: Rollers and suction systems require significant electrical energy.

VII. Relevance to Lahore, Pakistan

Draw frames are indispensable machines in every spinning mill in Lahore, forming a crucial link between the carding and subsequent spinning stages:

- Foundation for Quality Yarn: Given Lahore’s focus on producing high-quality yarn for both local textile industries and international exports, state-of-the-art draw frames with auto-levelling are essential for achieving the required evenness and strength.

- Handling Diverse Blends: Pakistani mills often work with various cotton types and blends. The draw frame’s blending capability is vital for creating a consistent final product from these diverse inputs.

- Productivity Drivers: High-speed draw frames are crucial for maintaining the high production rates necessary to meet market demands.

- Technological Adoption: Leading mills are continuously upgrading to the latest generation of draw frames from manufacturers like Rieter, Truetzschler, and Lakshmi, to leverage advanced auto-levelling and digital control for superior quality.

- Skilled Workforce: The precise settings and maintenance required for draw frames necessitate a well-trained and skilled workforce.

In summary, the Draw Frame is the unsung hero of the spinning preparatory section. By meticulously parallelizing fibers and ensuring unparalleled sliver uniformity through intelligent doubling and drafting, it lays a flawless foundation for the subsequent processes, directly impacting the final yarn’s quality, strength, and appearance.

This concludes our lecture on the Draw Frame. Next, we will discuss the Comber, an optional but important machine used for producing high-quality, fine yarns.