Secondary Treatment – Biological Degradation: Lecture 3

Overall Goal: To understand the principles and common technologies of biological treatment for textile wastewater, focusing on how microorganisms break down organic pollutants and prepare the water for advanced polishing.

3.1. Principles of Biological Treatment: Harnessing Nature’s Engineers

- The Microbial Workforce: Introduce the concept that microorganisms (primarily bacteria) are the “workers” in biological treatment. They consume organic matter (BOD, COD, and some color) as their food source for growth and energy.

- Aerobic vs. Anaerobic Processes:

- Aerobic: Requires oxygen. Best for soluble organic matter and typically produces less odor. Most common for textile wastewater after primary treatment.

- Anaerobic: Occurs in the absence of oxygen. Often used for highly concentrated waste streams or sludge, producing methane as a byproduct. Less common as a primary secondary treatment for textile effluent due to high sulfate content and varied influent.

- Key Factors for Success: Discuss the critical environmental conditions that influence microbial activity:

- Temperature: Optimal ranges for different bacterial communities.

- pH: The importance of maintaining a neutral pH range (6.5-8.5).

- Nutrient Balance (C:N:P): Why a balanced ratio of carbon (organic pollutants), nitrogen, and phosphorus is essential for microbial growth.

- Dissolved Oxygen (DO): Crucial for aerobic processes; too little or too much can hinder efficiency.

- Toxicity: How certain textile chemicals (e.g., specific dyes, heavy metals) can inhibit or kill beneficial microorganisms.

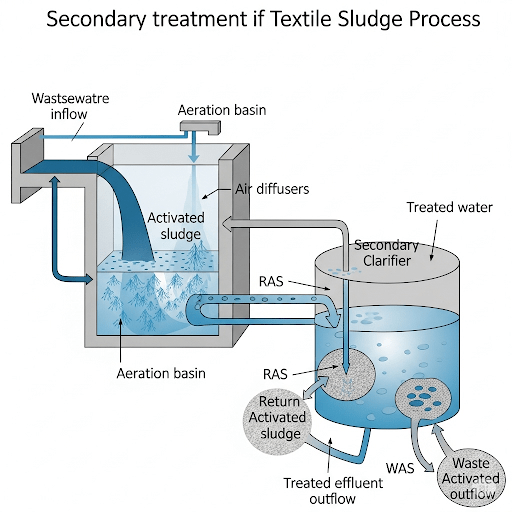

3.2. Activated Sludge Process: The Workhorse of Wastewater Treatment

- Core Concept: This is the most widely used biological treatment method. It involves a “mixed liquor” of wastewater and active microorganisms (activated sludge) that are aerated in a reactor, followed by a clarifier to separate the treated water from the biomass.

- Components:

- Aeration Basin/Reactor: Where the active biomass (microbes) are vigorously mixed with the wastewater and supplied with oxygen (via diffusers or surface aerators). This is where the bulk of organic breakdown occurs.

- Secondary Clarifier: A sedimentation tank (similar in principle to primary clarifiers) that separates the treated water (effluent) from the activated sludge.

- Sludge Return (RAS): A portion of the settled activated sludge is continuously returned to the aeration basin to maintain a high concentration of active microorganisms.

- Waste Activated Sludge (WAS): Excess sludge is removed for further processing.

- Variants:

- Conventional Activated Sludge: Continuous flow system.

- Extended Aeration: A variant designed for longer retention times and lower organic loading, often leading to less sludge production.

- Sequencing Batch Reactor (SBR): A popular “fill-and-draw” system where all treatment steps (fill, react, settle, draw) occur sequentially in a single tank. Advantages for Textile Wastewater: High flexibility for variable flow/load, better control, and can sometimes achieve better color removal compared to continuous systems.

- Pollutant Removal: Highly effective in reducing Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). Can also achieve some reduction in color, especially for biodegradable dyes.

3.3. Biological Filters (Trickling Filters, Rotating Biological Contactors – RBCs): Fixed-Film Systems

- Fixed-Film Principle: Unlike activated sludge where microbes are suspended, fixed-film systems grow microorganisms on a solid medium (e.g., rocks, plastic media).

- Trickling Filters: Wastewater is sprayed over a bed of media, and a biofilm grows on the surface. Oxygen is supplied by natural air circulation.

- Rotating Biological Contactors (RBCs): Large, rotating discs covered with media slowly rotate through the wastewater, exposing the biofilm alternately to the wastewater and air.

- Advantages/Disadvantages: Generally more robust to shock loads and simpler to operate than activated sludge, but may have lower overall removal efficiencies for complex compounds and can sometimes produce odors. Less commonly the sole secondary treatment for high-strength textile waste.

3.4. Membrane Bioreactors (MBRs): The Future of Biological Treatment

- Hybrid Technology: MBRs combine the activated sludge process with a membrane filtration unit (typically ultrafiltration or microfiltration) within the same reactor.

- How it Works: The membranes act as a physical barrier, retaining all the activated sludge within the reactor while allowing only clean water to pass through.

- Advantages:

- Superior Effluent Quality: Produces very high-quality effluent, virtually free of suspended solids, bacteria, and viruses.

- Smaller Footprint: Can operate with much higher concentrations of biomass (MLSS), requiring smaller aeration tanks.

- Reduced Sludge Production: Higher sludge retention times can lead to less waste sludge.

- Eliminates Secondary Clarifier: The membranes replace the need for a separate clarifier.

- Challenges:

- Membrane Fouling: The main operational challenge, requiring regular cleaning and careful control.

- Higher Energy Consumption: For aeration and membrane operation.

- Higher Capital Cost: Compared to conventional activated sludge.

- Pollutant Removal: Excellent for TSS, BOD/COD removal, and some color reduction. The effluent quality from MBRs is often directly suitable for advanced tertiary treatment like reverse osmosis, making it a strong contender for textile water reuse schemes.

This lecture will provide a solid understanding of how living organisms play a crucial role in breaking down the complex organic load of textile wastewater, bringing us closer to water suitable for reuse.