Lecture #20: A Deeper Dive into Dye Chemistry – Part 6: Azoic Dyes (Naphthol Dyes)

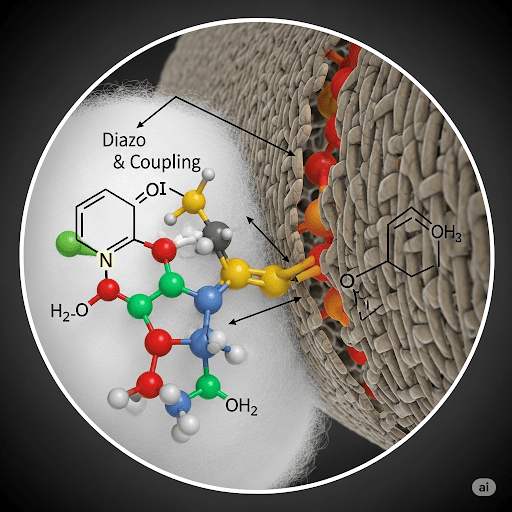

Welcome to Lecture #20! Today, we’re exploring Azoic Dyes, also commonly known as Naphthol Dyes. These dyes are unique because, unlike the others we’ve discussed so far, they aren’t pre-formed dye molecules applied to the fabric. Instead, the final insoluble dye pigment is synthesized directly within the fiber through a chemical coupling reaction. This in-situ formation is what gives them excellent fastness properties, particularly to washing.

1. Introduction to Azoic Dyes

- Definition: Azoic dyes are a class of synthetic dyes that are formed directly on the cellulosic fiber by the reaction (coupling) of two colorless components: a naphthol (or azoic coupling component) and a diazonium salt (or azoic diazo component). The resulting azo pigment is insoluble in water and physically trapped within the fiber.

- Key Feature: The characteristic feature is the in-situ formation of the dye. This means the dye molecule is “built” inside the fiber, ensuring superb wash fastness.

- Primary Application: Exclusively used for cellulosic fibers such as cotton, linen, and viscose rayon. They are not suitable for protein fibers due to the highly alkaline conditions required for applying the naphthol component.

- Historical Significance: The first commercial azoic dye was Para Red in 1880, followed by the development of various naphthols and diazo components, allowing for a wide range of shades.

2. Chemical Components of Azoic Dyes

Azoic dyeing involves two main chemical components, neither of which is a dye on its own:

a) Naphthol (Azoic Coupling Component)

- These are typically derivatives of β-naphthol, acetoacetarylamides, or hydroxynaphthoic anilides.

- They contain an active methylene or phenolic hydroxyl group that can react with a diazonium salt.

- In alkaline solution, the naphthol forms a naphtholate anion, which is the highly reactive species for coupling.

- General Structure (Example: Naphthol AS series):

Ar-NH-CO-CH(OH)-C10H6(Where Ar is an aromatic group, C10H6 represents the naphthol nucleus) - Key Property: Naphthols are usually water-insoluble and are applied by padding or impregnating the fabric with an alkaline solution.

b) Diazonium Salt (Azoic Diazo Component)

- These are prepared by the diazotization of aromatic amines (anilines). The amine is reacted with nitrous acid (formed from sodium nitrite and a mineral acid like HCl) at low temperatures (0−5∘C).

- General Reaction for Diazotization: Ar−NH2+NaNO2+2HCl0−5∘C

[Ar−N≡N]+Cl−+NaCl+2H2O Where Ar is an aromatic group.

- Key Property: Diazonium salts are unstable, particularly at higher temperatures, and must be prepared freshly or kept cool. They are strong electrophiles and will react with the electron-rich naphtholate anion.

3. Mechanism of Dyeing (The Two-Stage Process)

Azoic dyeing is a two-stage process, followed by thorough washing.

Stage 1: Naphtholation (Impregnation)

- The fabric is impregnated (padded or immersed) in an alkaline solution of the naphthol component.

- The naphthol, usually supplied as an insoluble powder, is first pasted with a small amount of water, then dispersed/dissolved with hot caustic soda (NaOH) and a dispersing agent (like Turkey Red Oil or sodium hydroxide). This forms the water-soluble naphtholate anion.

- The fabric then adsorbs these naphtholate anions. The concentration of naphthol on the fiber is crucial for the final shade depth.

- After impregnation, the fabric is typically squeezed to remove excess solution and sometimes dried or partially dried to ensure uniform distribution of the naphthol within the fiber.

Stage 2: Diazotization and Coupling (Development)

- The naphthol-impregnated fabric is then passed through a cold solution of the freshly prepared diazonium salt.

- As the diazonium salt comes into contact with the naphtholate anions present within the fiber, a rapid azo coupling reaction occurs.

- This reaction forms an insoluble azo pigment directly within the amorphous regions of the fiber.

- General Coupling Reaction: [Ar−N≡N]+Cl−+Naphthol−Cold

Ar−N=N−Naphthol+HCl The Ar−N=N−Naphthol represents the final insoluble azo dye pigment.

- The formed pigment is now physically entrapped within the fiber structure, just like vat dyes, but through a different chemical route.

- Color Development: The color appears instantly upon coupling, and the shade depends on the specific combination of naphthol and diazo component used.

Aftertreatment:

- Rinsing: The fabric is thoroughly rinsed to remove unreacted chemicals and surface dye.

- Soaping: A critical step. The fabric is boiled in a dilute non-ionic detergent solution. This helps to:

- Remove any surface-deposited pigment, which can lead to poor rub fastness.

- Agglomerate the fine dye particles formed within the fiber, improving crystal growth and enhancing the brilliance and fastness properties (especially rubbing and washing fastness).

- Final Rinsing: Cold rinse to remove soap.

4. Fastness Properties

- Washfastness: Excellent to outstanding due to the dye’s insolubility and its formation inside the fiber.

- Lightfastness: Good to very good, generally improving with darker shades.

- Rubfastness (Crocking): Good, provided thorough soaping is carried out. Poor soaping can lead to significant rubbing.

- Bleaching Fastness: Generally good, though can vary.

- Shade: Produces very bright and vivid shades, particularly in reds, oranges, yellows, and browns. Blues and greens are also possible but often achieved through mixing components.

5. Advantages and Disadvantages

Advantages:

- Excellent Wet Fastness: Outstanding wash and perspiration fastness due to the dye’s insolubility and in-situ formation.

- Brilliant Shades: Produces a wide range of very bright and intense colors, often unmatched by other dye classes for certain hues.

- Cost-Effective: Generally more economical than reactive dyes for achieving high fastness, especially for deeper shades.

- Good Lightfastness: Generally good resistance to fading from light.

Disadvantages:

- Complex Application Process: Requires two distinct stages and precise control of conditions (temperature, pH, concentration). The instability of diazonium salts adds to the complexity.

- Limited Color Range: While bright, the available color palette is somewhat limited compared to the vast range of reactive dyes, especially for certain blues and greens.

- Sensitive to Acids: The formed azo pigment can be sensitive to strong acids, which can cause hydrolysis and color change.

- Environmental Concerns: Handling of unstable diazonium salts and the presence of toxic components can pose safety and environmental challenges in the dyehouse. Proper waste treatment is essential.

- Poor Leveling: If not applied carefully, uneven dyeing can occur due to the rapid coupling reaction.

- Not Suitable for Blends: Difficult to dye blends of cellulosic and non-cellulosic fibers effectively.

6. Practical Considerations

- Temperature Control: Both stages require strict temperature control; cold for diazotization and coupling, and often hot for naphtholation.

- Chemical Stability: Diazonium salts are highly unstable and must be used immediately after preparation and kept chilled.

- Fiber Preparation: The fiber must be thoroughly prepared (desized, scoured, bleached) to ensure uniform absorption of the naphthol.

- Combination Dyeing: Different shades can be achieved by using combinations of various naphthols and diazo components.

Azoic dyes, despite their application complexity, remain crucial for textiles requiring vibrant, high-fastness colors, especially for items like shirting fabrics, furnishing fabrics, and certain types of workwear. They represent a clever chemical solution to the challenge of achieving permanent coloration.