Lecture #19: A Deeper Dive into Dye Chemistry – Part 5: Sulfur Dyes

Welcome to Lecture #19! Today, we’re focusing on Sulfur Dyes, a class of dyes characterized by the presence of sulfur linkages within their molecular structure. Like vat dyes, they are applied through a reduction-oxidation process, as they are insoluble in their original form.

1. Introduction to Sulfur Dyes

- Definition: Sulfur dyes are complex organic compounds containing sulfur, often in polysulfide linkages, that are insoluble in water. They require reduction to a water-soluble, substantive leuco form for application to textile fibers, followed by oxidation to regenerate the insoluble pigment within the fiber.

- Key Feature: The presence of sulfur atoms in their chromophoric system and their application via a redox process are defining characteristics. They are most famous for producing heavy, dull shades, especially blacks, browns, and navies.

- Historical Significance: The first sulfur dye, “Cachou de Laval,” was synthesized in 1873. Their commercial importance grew rapidly, especially for black shades, due to their low cost and good fastness properties.

- Primary Application: Exclusively used for cellulosic fibers (cotton, linen, rayon) due to the strong alkaline conditions required for their application.

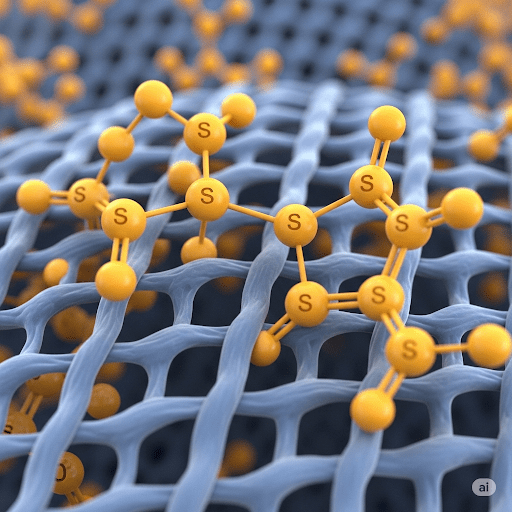

2. Chemical Structure of Sulfur Dyes

The exact chemical structures of many commercial sulfur dyes are complex and often not fully elucidated, as they are polymeric mixtures formed by the reaction of organic compounds with sulfur or polysulfides. However, they are generally characterized by:

- Polymeric Structure: They are often high molecular weight, oligomeric or polymeric compounds containing sulfur atoms linked in various ways (e.g., -S-, -S-S-).

- Chromophores: The chromophoric systems are diverse, often involving thiophene, thiazine, or other sulfur-containing heterocyclic rings. They derive their color from extensive conjugation within these complex sulfur-containing structures.

- Example (Simplified): While a single definitive chemical formula is difficult, consider the general principle of aromatic compounds reacting with sulfur to form complex, fused ring systems with sulfur bridges.

- For instance, a common pathway involves the sulfurization of organic compounds like dinitrophenols, indophenols, or aminophenols.

- A very simplified representation of a sulfur linkage: Dye−S−S−Dye′ Or often more complex polysulfide bridges within a polymeric network.

3. Mechanism of Dyeing (The Three Stages)

Similar to vat dyes, sulfur dyes are applied via a three-stage reduction-oxidation process:

Stage 1: Reduction (Sulfurization)

- The insoluble sulfur dye is converted into a water-soluble, substantive leuco form (thio-hydroxy or thiol form). This reduction is typically carried out using sodium sulfide (Na$_2$S) as the reducing agent, which also acts as an alkali.

- Reducing Agent: Sodium sulfide is the characteristic reducing agent for sulfur dyes. It’s milder than sodium hydrosulfite used for vat dyes, making it suitable for prolonged dyeing without excessive fiber degradation.

- Alkali: Sodium sulfide also provides the necessary alkalinity for the reduction and solubilization of the leuco form.

- Process: The insoluble sulfur dye is dispersed in water, and sodium sulfide is added along with soda ash (Na$_2$CO$_3$) to maintain alkalinity, especially for deeper shades. The mixture is heated.

- Chemical Reaction Example (Conceptual):

- Insoluble (Oxidized) Sulfur Dye (polymeric network with disulfide bonds): Dye−S−S−Dye′

- Reduction by Sodium Sulfide: The disulfide bonds are broken, and thiol groups are formed, which ionize in alkaline conditions to form soluble thiolate anions. Dye−S−S−Dye′+Na2SAlkali, Heat

Dye−S−Na++Dye′−S−Na+

- The leuco form is generally yellow to brown, often dull, and soluble.

Stage 2: Dyeing (Adsorption and Diffusion)

- The textile fiber (e.g., cotton) is immersed in the dye bath containing the water-soluble, anionic leuco form of the sulfur dye.

- The leuco dye molecules diffuse from the dye bath and are adsorbed onto the fiber surface and then penetrate into the amorphous regions.

- Electrolyte (Salt) Role: The addition of a neutral salt (e.g., NaCl or Na$_2$SO$_4$) is essential to promote the exhaustion of the anionic leuco dye onto the negatively charged cellulosic fiber.

- Temperature: Dyeing is typically carried out at high temperatures, often near boiling (80−100∘C), to facilitate rapid diffusion and exhaustion.

Stage 3: Oxidation

- After sufficient dye exhaustion, the fiber is removed from the dye bath and exposed to an oxidizing agent.

- The leuco dye molecules, now inside the fiber, are oxidized back to their original, insoluble, colored pigment form, which then becomes physically trapped within the fiber.

- Oxidizing Agents:

- Air (Atmospheric Oxygen): The most common and economical method. The fabric is simply exposed to air after dyeing. This is sometimes facilitated by “skying” (allowing the fabric to hang in the air).

- Chemical Oxidizing Agents: For more complete and uniform oxidation, milder chemical oxidizers like sodium bichromate (Na$_2$Cr$_2$O$_7$), hydrogen peroxide (H$_2$O$_2$), or sodium perborate can be used. These are particularly useful for deeper shades or if air oxidation is too slow.

- Chemical Reaction Example (Conceptual):

- Leuco form (soluble, adsorbed in fiber): Dye−S−Na+

- Oxidation (formation of polysulfide linkages, regeneration of insoluble dye): Dye−S−Na+Oxidizing Agent

Dye−S−S−Dye′

- Aftertreatment:

- Rinsing: To remove residual chemicals.

- Soaping: Boiling in a dilute non-ionic detergent solution helps remove surface dye and improves crocking fastness (resistance to rubbing).

- Fixing Agents: Sometimes, metal salts (e.g., copper sulfate, chromium acetate) are used as aftertreatments to improve lightfastness and wet fastness, especially for certain shades.

4. Fastness Properties

- Washfastness: Good to very good, due to the insolubility of the oxidized dye trapped within the fiber.

- Lightfastness: Generally good, though can vary depending on the specific dye.

- Rubfastness (Crocking): Moderate to good. Soaping is crucial to improve this.

- Bleaching Fastness: Poor to moderate; sulfur dyes are generally not resistant to strong oxidative bleaching agents like hypochlorite.

- Overall: Provide shades with good serviceability properties.

5. Advantages and Disadvantages

Advantages:

- Cost-Effective: One of the most economical dye classes, especially for dark shades like black and navy.

- Good Fastness Properties: Offer good wash and lightfastness, making them suitable for workwear, casual wear, and home textiles where durability is required.

- Deep, Heavy Shades: Capable of producing very deep and uniform shades.

- Easy to Apply: The dyeing process is relatively straightforward compared to vat dyes once the reduction bath is prepared.

Disadvantages:

- Limited Color Range: Predominantly restricted to dull shades of black, brown, olive, and navy. Bright colors are generally not achievable.

- Odor: Sulfur dyes can sometimes produce a characteristic sulfide odor during processing, which can be unpleasant.

- Fiber Degradation (Sulfur Tenderization): The presence of free sulfur or sulfuric acid (formed from oxidation of residual sulfur) can cause cellulose degradation, particularly if the fabric is stored under hot and humid conditions. This is known as “sulfur tenderization” and can lead to weakening or brittleness of the fabric. Careful washing, neutralization, and aftertreatment are crucial to minimize this.

- Effluent Issues: The dye bath effluent contains sulfides, which are toxic and require proper treatment before discharge. Heavy metal salts used in some aftertreatments also contribute to effluent concerns.

- Not Suitable for Bright Shades: Cannot produce the brilliant shades obtainable with reactive or direct dyes.

6. Environmental and Safety Considerations

- The presence of sodium sulfide (a strong alkali and reducing agent) and potential for hydrogen sulfide gas (H$_2$S) evolution (a highly toxic gas) requires good ventilation and safety precautions in the dyehouse.

- Effluent treatment is essential to remove sulfides and color before discharge.

Despite their limitations in color range and environmental considerations, sulfur dyes continue to be a vital class of dyes for specific applications where cost-effectiveness and good overall fastness for dark, dull shades are prioritized.