Introduction to Resource Recovery & Heat Recovery from Textile Wastewater: Lecture 1 (of New Series)

Overall Goal: To introduce the overarching concept of resource recovery in the context of textile wastewater, define its importance, and then delve specifically into the principles and technologies for recovering heat from hot effluent streams.

1.1. The Paradigm Shift: From Waste Treatment to Resource Recovery

- Beyond End-of-Pipe: Reiterate that conventional wastewater treatment focuses on meeting discharge limits or reuse standards. Resource recovery takes this a step further by seeking to extract valuable components from the waste stream.

- Drivers for Resource Recovery:

- Economic Value: Converting waste into marketable products or reusable inputs, leading to cost savings and new revenue streams.

- Environmental Sustainability: Reducing virgin resource consumption, minimizing waste generation, lowering greenhouse gas emissions, and decreasing reliance on fossil fuels.

- Regulatory Pressures: Evolving regulations increasingly incentivize or mandate resource recovery.

- Circular Economy Principles: Embedding the textile industry within a closed-loop system where resources are continually reused.

- Types of Resources to Recover: Briefly introduce the categories we will cover in this series:

- Heat (Thermal Energy): From hot wastewater.

- Chemicals: Dyes, caustic soda, sizing agents, etc.

- Energy: Biogas from organic matter.

- Materials: Fibers, plastics, other solids.

- Challenges of Resource Recovery: Discuss initial investment costs, technological complexity, quality of recovered resources, and market demand for recovered products.

1.2. The Low-Hanging Fruit: Heat Recovery from Hot Effluent

- The Energy Intensity of Textile Wet Processing: Emphasize that heating process baths (scouring, bleaching, dyeing, washing) consumes a significant portion (often 60-80%) of the total energy in a textile wet processing unit.

- The Source of Recoverable Heat: Hot wastewater streams (e.g., from washing, rinsing, dyeing discharge) that are often discharged at high temperatures (40-90°C).

- Why Recover Heat?

- Direct energy savings and reduced fuel consumption.

- Lower operational costs.

- Reduced greenhouse gas emissions.

- Improved thermal efficiency of the plant.

1.3. Principles and Technologies for Heat Recovery

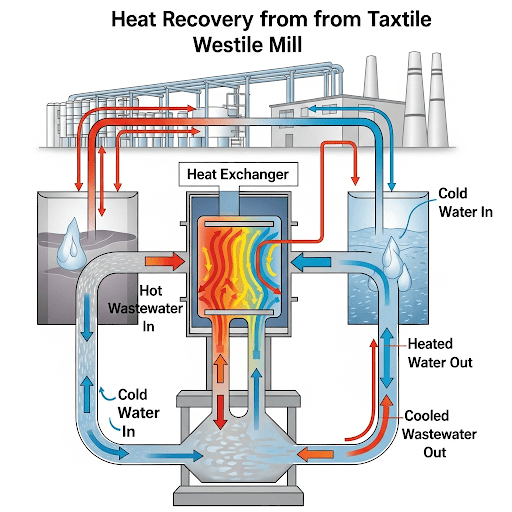

- Basic Principle: Heat Exchange: Transferring thermal energy from a hot fluid (wastewater) to a colder fluid (incoming fresh water or process water) without direct mixing.

- Types of Heat Exchangers Relevant to Textile Wastewater:

- Shell and Tube Heat Exchangers: Robust, but can be prone to fouling with suspended solids.

- Plate Heat Exchangers: Highly efficient, compact, but more susceptible to clogging and fouling.

- Spiral Heat Exchangers: Good for fluids with suspended solids, less prone to fouling.

- Scraped Surface Heat Exchangers: Designed for highly viscous or fouling fluids, often used for more challenging sludge or concentrates.

- Considerations for Textile Wastewater Heat Recovery:

- Fouling: The biggest challenge due to suspended solids, fibers, and chemical precipitates in wastewater. Discuss the need for robust pre-filtration (e.g., coarse screens, lint filters) and regular cleaning (CIP – Clean-In-Place systems).

- Corrosion: Potential issues from chemical constituents in wastewater.

- Temperature Differential: The effectiveness of heat transfer depends on the temperature difference between the hot and cold streams.

- Flow Rates: Matching flow rates for efficient heat transfer.

- Application Scenarios:

- Pre-heating incoming fresh water for dyeing/washing.

- Heating boiler feed water.

- Space heating (less common but possible).

- Economic Viability of Heat Recovery: High ROI and short payback periods for well-designed systems, making it often the first resource recovery initiative implemented.

1.4. Case Studies & Best Practices in Heat Recovery

- Real-World Examples: Showcase textile mills that have successfully implemented heat recovery systems, detailing the type of heat exchangers used, the energy savings achieved, and the challenges overcome.

- Integration with Overall Plant Design: How heat recovery systems are integrated seamlessly into the overall water and energy management strategy of a textile plant.

By the end of this lecture, you’ll understand why resource recovery is the next frontier in sustainable textile production, and you’ll have a solid grasp of the principles and practical applications of heat recovery from wastewater.