Integrated Resource Recovery Systems & Future Outlook: Lecture 5

Overall Goal: To synthesize the individual resource recovery concepts into a comprehensive, integrated system for textile wastewater, evaluate the benefits of such holistic approaches, and discuss future trends and emerging opportunities in the field.

5.1. The Vision: From Wastewater Treatment to Integrated Resource Factories

- Holistic Approach: Emphasize the shift from treating wastewater as a single problem to viewing it as a valuable resource stream from which multiple resources can be extracted.

- Synergies of Integration: Discuss how recovering one resource can positively impact the recovery of others (e.g., heat recovery reduces energy demand for chemical recovery, fiber removal improves efficiency of subsequent processes).

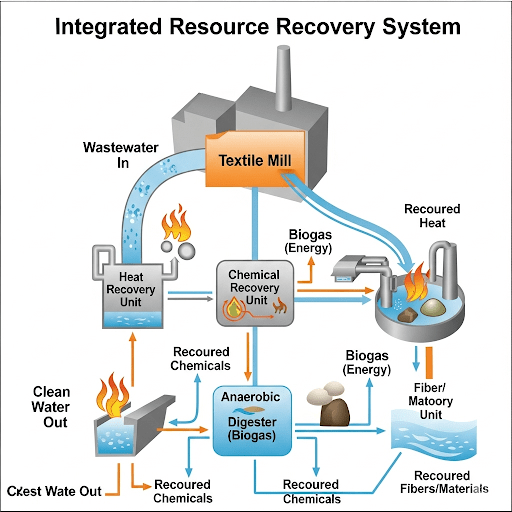

- The “Resource Factory” Concept: Envision a textile mill where wastewater is not just treated, but purposefully processed to maximize the recovery of water, energy, chemicals, and materials, minimizing external inputs and waste outputs.

5.2. Designing Integrated Resource Recovery Systems

- Process Flow Integration:

- Upstream Measures: Reiterate the importance of process optimization, water minimization, and chemical substitution at the source to reduce the load on recovery systems.

- Sequential Recovery: Discuss the logical order of implementing recovery steps (e.g., fiber recovery first to protect downstream equipment, followed by heat recovery, then chemical recovery, and finally energy recovery from concentrated sludge/streams).

- Water Loops & Cascading Use: Integrate recovered water of different qualities back into appropriate processes (e.g., wash water reuse, boiler feed water).

- Technology Stacking: How different technologies (e.g., advanced filtration, evaporation, anaerobic digestion, specialized chemical processes) are combined and optimized to work together.

- Monitoring & Control: The crucial role of advanced monitoring and automation (revisited from Lecture 8 of the previous series) in optimizing the performance of integrated systems and ensuring the quality of recovered resources.

5.3. Economic & Environmental Benefits of Integrated Systems

- Maximized Cost Savings: Sum up the cumulative savings from reduced fresh water intake, lower energy bills, decreased chemical purchases, and minimized waste disposal costs.

- Enhanced Environmental Performance: Significant reduction in pollution load, lower greenhouse gas emissions, decreased virgin resource consumption, and a stronger contribution to circular economy principles.

- Competitive Advantage: How integrated resource recovery can enhance a textile mill’s brand image, meet stringent international sustainability standards, and provide a competitive edge in the global market.

- Risk Mitigation: Reduced exposure to fluctuating resource prices and increasingly strict environmental regulations.

5.4. Challenges and Considerations for Integrated Systems

- High Initial Capital Investment: Integrated systems are complex and require substantial upfront investment.

- Technical Complexity: Requires skilled personnel for design, operation, and maintenance.

- Space Requirements: Can demand significant land area, though compact designs are emerging.

- Interdependencies: A malfunction in one recovery unit can impact the performance of others.

- Quality of Recovered Resources: Ensuring the recovered water, chemicals, and energy meet the required purity and quality standards for reuse.

- Regulatory & Policy Support: The need for supportive policies, incentives, and frameworks that encourage holistic resource recovery, particularly in regions like Lahore, Punjab, Pakistan.

5.5. Future Trends & Opportunities in Resource Recovery

- Advanced Materials from Waste: Exploring opportunities for recovering high-value materials beyond traditional fibers (e.g., dyes as pigments, advanced biopolymers).

- Digitalization & AI: The increasing role of artificial intelligence, machine learning, and digital twins in optimizing integrated recovery systems, predicting failures, and improving efficiency.

- Decentralized Solutions: Smaller, modular recovery units that can be implemented at specific process points.

- Cross-Sectoral Collaboration: Opportunities for textile waste to be used as a resource in other industries (e.g., chemical industry, agriculture).

- Net-Zero Textiles: The ultimate goal where textile production aims for minimal to zero environmental impact, with integrated resource recovery as a cornerstone.

By the end of this lecture, you will have a holistic understanding of how combining various resource recovery strategies can lead to a truly sustainable and economically viable textile industry, transforming wastewater from a liability into a valuable asset.