Fortifying the Threads: Supply Chain Resilience in Bangladesh’s Textile Sector – Lessons Learned and Future Strategies

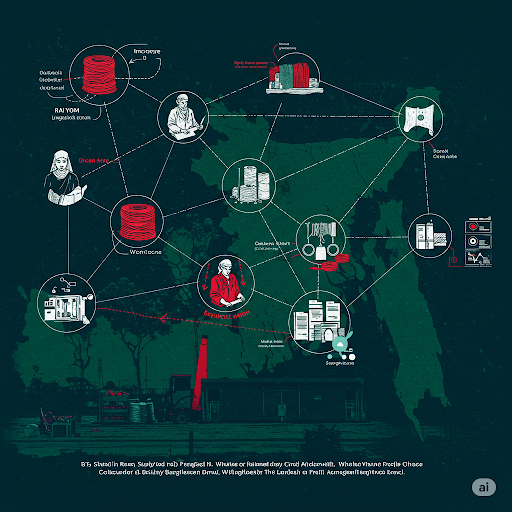

Bangladesh’s textile industry, the engine of its export economy, has long navigated a complex global supply chain. However, recent years have laid bare vulnerabilities, from the COVID-19 pandemic to geopolitical tensions and climate-related disruptions.

Building supply chain resilience is no longer a matter of optimization but a critical imperative for the sector’s future sustainability and growth. This article analyzes the lessons learned from recent disruptions and outlines future strategies for creating more robust and agile supply chains for Bangladesh’s textile manufacturers.

The Anatomy of Disruption: Lessons from the Recent Past

The past few years have served as a harsh but valuable learning experience for the global supply chain, and Bangladesh’s textile sector was not immune:

- The COVID-19 Pandemic (2020-2023): Lockdowns, port closures, and reduced global demand led to order cancellations, production halts, and significant delays in raw material sourcing and shipment of finished goods. This highlighted the industry’s reliance on geographically concentrated sourcing and the fragility of just-in-time inventory management.

- Geopolitical Instability (Ongoing): Trade wars, sanctions, and regional conflicts have created uncertainty and disrupted established trade routes, impacting the flow of raw materials and market access.

- Climate Change Impacts (Increasing Frequency): Extreme weather events like floods, cyclones, and heatwaves in Bangladesh and sourcing regions have caused production shutdowns, damaged infrastructure, and disrupted transportation, underscoring the vulnerability of the supply chain to environmental factors.

- Raw Material Price Volatility (Ongoing): Fluctuations in cotton prices, driven by weather patterns, trade policies, and global demand, have squeezed profit margins and created instability for manufacturers.

- Shipping and Logistics Bottlenecks (Recent): Port congestion, container shortages, and rising freight costs have added significant delays and expenses to the supply chain.

- Ethical Sourcing Concerns and Regulatory Changes (Ongoing): Increasing scrutiny on labor practices and environmental standards necessitates greater transparency and compliance throughout the supply chain, adding complexity and potential costs.

These disruptions have exposed several key weaknesses in the traditional linear and often geographically concentrated supply chains relied upon by many Bangladeshi textile manufacturers. The need for a more agile, diversified, and transparent approach has become abundantly clear.

Weaving a Stronger Fabric: Future Strategies for Supply Chain Resilience

Building a more robust supply chain for Bangladesh’s textile sector requires a multi-pronged approach encompassing diversification, technology adoption, collaboration, and a focus on sustainability:

1. Diversification of Sourcing and Manufacturing:

- Geographic Diversification: Reducing reliance on a single country or region for raw materials and exploring alternative sourcing locations can mitigate the impact of localized disruptions. This includes looking at emerging markets and strengthening regional partnerships.

- Supplier Diversification: Cultivating relationships with a wider pool of suppliers for key inputs can reduce dependence on individual vendors and provide alternative options during crises.

- Exploring Domestic Backward Linkages: Strengthening local production of raw materials like cotton and man-made fibers can reduce reliance on imports and create a more self-sufficient supply chain.

2. Embracing Digital Transformation and Technology:

- Supply Chain Visibility Platforms: Implementing digital platforms that provide real-time tracking of goods, inventory levels, and potential disruptions across the entire supply chain.

- AI-Powered Predictive Analytics: Utilizing AI to forecast demand fluctuations, identify potential risks, and optimize inventory management, moving beyond reactive approaches.

- Blockchain for Transparency and Traceability: Leveraging blockchain technology to create secure and transparent records of product origin, material sourcing, and production processes, enhancing accountability and building trust with buyers.

- IoT for Real-time Monitoring: Deploying IoT sensors to monitor production processes, warehouse conditions, and transportation, enabling proactive intervention and preventing delays or quality issues.

3. Fostering Collaboration and Partnerships:

- Strengthening Buyer-Supplier Relationships: Moving towards more collaborative and long-term partnerships with international buyers, involving shared risk and responsibility.

- Industry-Wide Collaboration: Sharing information and best practices among manufacturers, potentially through industry associations, to collectively address supply chain challenges.

- Logistics Partnerships: Developing stronger relationships with reliable logistics providers and exploring alternative transportation modes to mitigate shipping disruptions.

4. Prioritizing Sustainability and Ethical Practices:

- Building Sustainable and Circular Supply Chains: Focusing on sourcing sustainable raw materials, reducing waste, and implementing circular economy principles to enhance environmental resilience and meet evolving consumer demands.

- Ensuring Ethical Labor Practices: Investing in fair wages, safe working conditions, and transparent labor practices throughout the supply chain to mitigate reputational risks and comply with international standards.

- Traceability of Sustainable Materials: Utilizing technology to ensure the traceability of sustainably sourced materials, providing verifiable proof to buyers.

5. Investing in Infrastructure and Capacity Building:

- Improving Port and Logistics Infrastructure: Advocating for and investing in upgrades to ports, transportation networks, and warehousing facilities to improve efficiency and reduce bottlenecks.

- Developing Local Expertise in Supply Chain Management: Investing in training and education programs to build a skilled workforce capable of managing complex and resilient supply chains.

6. Risk Assessment and Contingency Planning:

- Developing Comprehensive Risk Management Frameworks: Identifying potential risks across the supply chain and developing proactive mitigation strategies and contingency plans.

- Stress Testing Supply Chains: Regularly simulating potential disruption scenarios to identify vulnerabilities and evaluate the effectiveness of contingency plans.

- Maintaining Buffer Inventory (Strategically): While just-in-time has its benefits, strategically holding some buffer inventory of critical raw materials or finished goods can provide a cushion during disruptions.

Conclusion: Building a Resilient Future, Thread by Thread

The recent disruptions have served as a wake-up call for Bangladesh’s textile sector, highlighting the urgent need to build more resilient supply chains. By embracing diversification, leveraging digital technologies, fostering collaboration, prioritizing sustainability, investing in infrastructure, and implementing robust risk management strategies, the industry can fortify its foundations and navigate future uncertainties with greater agility and strength. Building supply chain resilience is not merely about mitigating risks; it’s about creating a more sustainable, efficient, and competitive future for Bangladesh’s most vital economic engine, ensuring it remains a reliable and responsible partner in the global apparel landscape. The threads of resilience, woven strategically today, will determine the strength and longevity of the industry tomorrow.