Energy Recovery: Biogas from Anaerobic Digestion of Sludge: Lecture 3

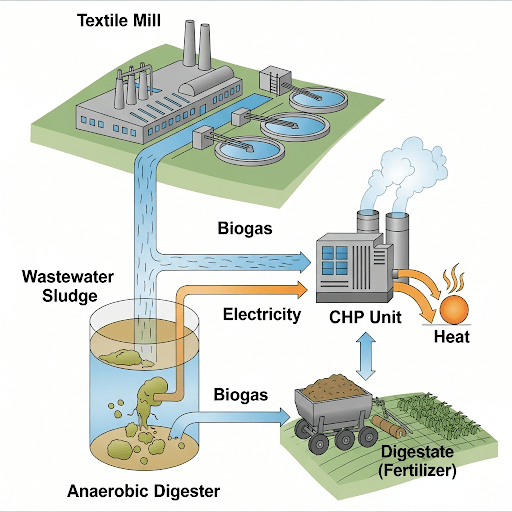

Overall Goal: To understand the principles and processes of anaerobic digestion for biogas production from textile wastewater sludge, and to evaluate its potential as a renewable energy source for textile mills.

3.1. The Energy Potential of Wastewater Sludge

- Sludge as a By-product: Revisit that sludge (solid waste generated during wastewater treatment) is a significant challenge in terms of disposal and cost.

- Organic Content: Emphasize that textile wastewater sludge, particularly from biological treatment (activated sludge), is rich in organic matter.

- The “Waste to Energy” Concept: Introduce the idea that instead of being a disposal burden, this organic content can be converted into valuable renewable energy, specifically biogas.

- Benefits of Sludge Treatment with Energy Recovery:

- Reduced Sludge Volume: Anaerobic digestion significantly reduces the amount of sludge, lowering disposal costs.

- Energy Generation: Produces biogas (a mixture of methane and carbon dioxide) that can be used for heat or electricity.

- Odor Reduction: Stabilizes organic matter, reducing odors.

- Pathogen Reduction: Improves sludge quality.

- Greenhouse Gas Reduction: Capturing methane (a potent GHG) instead of releasing it.

3.2. Principles of Anaerobic Digestion

- Definition: A biological process where microorganisms break down organic matter in the absence of oxygen to produce biogas.

- Microbial Stages: Explain the four main stages:

- Hydrolysis: Complex organic polymers are broken into simpler molecules.

- Acidogenesis: Simple molecules are converted into volatile fatty acids (VFAs), hydrogen, and carbon dioxide.

- Acetogenesis: VFAs are converted into acetate, hydrogen, and carbon dioxide.

- Methanogenesis: Acetate, hydrogen, and carbon dioxide are converted into methane (CH4) and carbon dioxide (CO2) by methanogenic bacteria.

- Key Factors for Digestion: Temperature (mesophilic vs. thermophilic), pH, retention time, nutrient balance, and inhibition by toxic substances (relevant for industrial sludge).

3.3. Technologies for Anaerobic Digestion in Textile Context

- Digester Types:

- Conventional/Complete Mix Digesters: Large, continuously stirred tanks.

- Upflow Anaerobic Sludge Blanket (UASB) Reactors: Granular sludge bed, efficient for low-strength wastewater, can also be adapted for sludge.

- High-Rate Digesters: Designed for higher organic loading rates, often using granular or immobilized biomass.

- Pre-treatment of Sludge: Discuss the importance of sludge thickening to increase organic loading and sometimes hydrolysis (thermal, chemical, mechanical) to enhance biogas yield by breaking down complex organic structures.

- Biogas Composition & Utilization:

- Typically 50-75% methane, 25-50% carbon dioxide, plus trace gases (H2S).

- Direct Use: Burned in boilers for heating process water or space.

- Combined Heat and Power (CHP) / Cogeneration: Used in specialized engines to generate both electricity and heat.

- Biomethane/Bio-CNG Production: Upgrading biogas by removing CO2 and H2S to achieve pipeline quality natural gas or vehicle fuel (more complex, higher cost).

3.4. Challenges and Opportunities in Textile Sludge Digestion

- Challenges:

- Inhibitory Compounds: Dyes, heavy metals, high salinity, or specific chemicals in textile sludge can inhibit microbial activity.

- Variable Sludge Composition: Textile sludge can vary significantly depending on the processes, making stable digestion challenging.

- Capital Cost: Initial investment for digesters and biogas handling systems.

- Odor Management: Need for proper handling of biogas (especially H2S) and digestate.

- Opportunities:

- Co-digestion: Mixing textile sludge with other organic wastes (e.g., municipal sewage sludge, food waste) to improve nutrient balance and biogas yield.

- Policy Support: Government incentives for renewable energy production.

- Circular Economy Integration: Transforming a waste into a valuable energy resource within the textile industry’s sustainability efforts.

3.5. Case Studies in Biogas Production from Industrial Sludge

- Real-World Examples: Showcase textile mills or industrial parks where anaerobic digestion has been successfully implemented for energy recovery from sludge, detailing the system, energy generated, and lessons learned.

- Economic Viability: Discuss the payback period and long-term savings from reduced energy bills and sludge disposal costs.

By the end of this lecture, you’ll understand how textile wastewater sludge can be transformed from a costly waste product into a valuable source of renewable energy through anaerobic digestion, contributing significantly to a mill’s energy independence and environmental footprint reduction.