Disperse Dyes: Lecture #21: A Deeper Dive into Dye Chemistry – Part 7

Welcome to Lecture #21! Today, we’re shifting our focus significantly to a class of dyes essential for synthetic fibers: Disperse Dyes. Unlike the water-soluble dyes we’ve primarily discussed (Direct, Reactive, Acid, Basic), disperse dyes are inherently hydrophobic and are applied from an aqueous dispersion rather than a true solution. This unique characteristic makes them perfect for dyeing synthetic polymers like polyester, acetate, and nylon.

1. Introduction to Disperse Dyes

- Definition: Disperse dyes are non-ionic, low-molecular-weight organic compounds that are sparingly soluble in water. They are applied from an aqueous dispersion, often with the help of dispersing agents, and primarily dye hydrophobic synthetic fibers.

- Key Feature: Their insolubility in water and their finely divided particulate form. They are absorbed by the fiber through a “solid solution” mechanism.

- Primary Application: The most important class of dyes for polyester (PET), cellulose acetate, triacetate, and to a lesser extent, nylon and acrylics. They are not suitable for natural fibers like cotton or wool.

- Historical Significance: Disperse dyes were initially developed for cellulose acetate fibers in the 1920s. With the rise of polyester in the mid-20th century, their importance dramatically increased, leading to the development of high-temperature dyeing methods.

2. Chemical Structure of Disperse Dyes

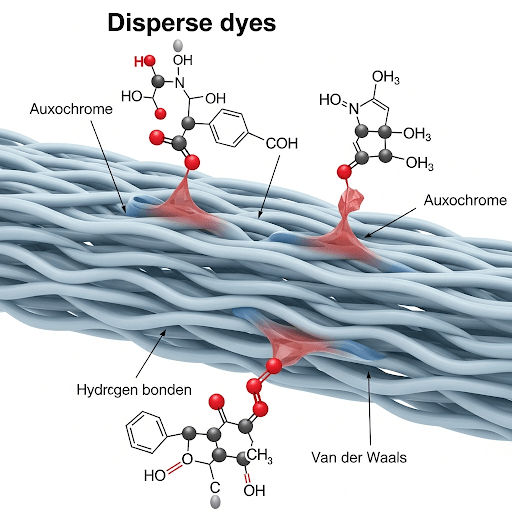

Disperse dyes are characterized by their relatively small, non-ionic, and largely planar molecular structures. They lack the ionic (sulfonic acid or carboxyl) groups found in many other dye classes, which is why they have very low water solubility.

- Chromophores: The most common chromophores are azo (-N=N-) and anthraquinone derivatives. Other chromophores include nitroarylamine and methine.

- Absence of Solubilizing Groups: Crucially, they do not contain strong water-solubilizing groups like −SO3Na or −COOH. Instead, they rely on small polar groups (-OH, -NH2, -CN, -Cl, -NO2) to provide some polarity and contribute to their affinity for the hydrophobic fibers without making them water-soluble.

- Molecular Weight: Generally low to medium molecular weight to facilitate diffusion into the tightly packed synthetic fibers.

- Particle Size: In their commercial form, they are supplied as finely ground particles (0.5−2μm) stabilized by dispersing agents.

Examples of common structures:

- Azo Disperse Dyes: Often monoazo or disazo.

- Example: A typical structure might involve substituted aniline and naphthol or phenylpyrazolone derivatives.

- Ar1-N=N-Ar2 (Where Ar1 and Ar2 are substituted aromatic rings with non-ionic polar groups.)

- Anthraquinone Disperse Dyes:

- Example: Derivatives of anthraquinone with various substituent groups.

O C // \\ C C // \\ C C | | C C \\ // C C \\ // O C(General anthraquinone core, with substituents like −NH2, −OH, alkyl groups etc.)

3. Mechanism of Dyeing (Solid Solution Theory)

The dyeing mechanism of disperse dyes is often explained by the “solid solution” theory or “solution-diffusion” mechanism:

- Preparation of Dispersion: The insoluble disperse dye powder is finely ground and mixed with water and dispersing agents. These agents (e.g., lignin sulfonates, naphthalene sulfonates) form a protective layer around the dye particles, preventing them from aggregating and maintaining a stable dispersion in the dye bath.

- Dye Transfer to Fiber Surface: When the fiber is introduced into the dye bath, a small amount of dye dissolves from the dispersed particles into the aqueous phase. An equilibrium is established between the solid dye in the bath and the dissolved dye.

- Fiber Swelling and Dye Diffusion:

- For hydrophobic synthetic fibers like polyester, high temperatures (typically 120−130∘C for polyester) are required. At these temperatures, the polymer chains in the amorphous regions of the fiber gain increased kinetic energy, allowing them to oscillate and create temporary “voids” or free volume.

- These voids allow the small, non-ionic dye molecules to diffuse from the surface into the interior of the fiber.

- Carriers (for atmospheric dyeing): In some cases (e.g., polyester at lower temperatures, or cellulose triacetate), dyeing carriers (e.g., biphenyl, o-phenylphenol, chlorinated benzenes) are used. These are organic chemicals that temporarily swell the fiber structure, assisting the diffusion of dye molecules into the fiber at lower temperatures. They act as “internal plasticizers.” However, due to environmental and health concerns, their use has significantly decreased with the advent of high-temperature and high-pressure dyeing machines.

- Solid Solution Formation: Once inside the fiber, the dye molecules are held by weak Van der Waals forces and hydrogen bonding (if polar groups are present). They essentially form a “solid solution” within the polymer matrix of the fiber. The dye is not chemically bonded but physically dissolved within the fiber.

- Equilibrium: Dyeing continues until an equilibrium is reached between the dye concentration in the dye bath and the dye concentration within the fiber.

4. Dyeing Process

Disperse dyes are applied using various methods, with the choice depending on the fiber type and desired fastness:

- High-Temperature (HT)/High-Pressure Dyeing (for Polyester):

- This is the most common method for polyester. Dyeing is carried out in pressurized dyeing machines (like jiggers, jets, or beams) at temperatures typically between 120−130∘C.

- The high temperature causes the polyester fibers to swell, allowing the dye to diffuse effectively.

- The pH is usually slightly acidic (4.5−5.5) to prevent hydrolysis of the polyester fiber.

- Carrier Dyeing (for Polyester, older method):

- Used when high-temperature dyeing equipment isn’t available. Dyeing is carried out at atmospheric boil (95−100∘C) with the addition of a carrier.

- Thermosol Dyeing (Continuous Method for Polyester/Cotton Blends):

- A continuous process where fabric is padded with a disperse dye dispersion, dried, and then exposed to high dry heat (180−220∘C) for a short time. The heat causes the dye to diffuse into the fiber. This method is particularly useful for polyester/cotton blends where the disperse dye dyes the polyester and another dye class (e.g., reactive, direct) dyes the cotton.

- Pad-Batch/Exhaust Dyeing (for Acetate/Nylon):

- Lower temperatures (70−85∘C) are typically used for cellulose acetate and nylon, as these fibers swell more easily and are more sensitive to high temperatures.

Aftertreatment:

- Reduction Clearing (for deep shades on Polyester): For deep shades on polyester, a “reduction clearing” step is often performed. This involves treating the dyed fabric with a reducing agent (e.g., sodium hydrosulfite) and caustic soda at high temperatures. This removes any dye aggregated on the fiber surface, significantly improving rubbing fastness (crocking) and preventing bleeding.

- Rinsing: To remove residual chemicals and unfixed dye.

5. Fastness Properties

- Washfastness: Generally good to excellent, especially on polyester, due to the dye’s insolubility in water and its physical entrapment.

- Lightfastness: Good to very good.

- Sublimation Fastness: Crucial for disperse dyes on polyester. This refers to the dye’s resistance to subliming (going directly from solid to gas) at high temperatures. Dyes with high sublimation fastness are required for high-temperature processing (thermosol, heat setting).

- Rubfastness (Crocking): Can be an issue if surface dye isn’t properly removed; reduction clearing helps significantly.

- Overall: Provide excellent all-around fastness properties suitable for the demanding end-uses of synthetic fibers.

6. Advantages and Disadvantages

Advantages:

- Excellent Fastness: Provides outstanding wash, light, and rub fastness, particularly on polyester.

- Wide Color Range: Available in a very broad spectrum of bright and vibrant colors.

- Versatility for Synthetics: The primary dye class for dyeing polyester, acetate, and triacetate, which are otherwise difficult to dye due to their hydrophobic nature.

- Good Leveling: Tend to have good leveling properties due to their molecular size and application mechanism.

Disadvantages:

- High Temperature/Pressure Requirements (for Polyester): Requires specialized and energy-intensive high-temperature/high-pressure dyeing equipment, increasing processing costs.

- Environmental Concerns: Carriers, when used, can be toxic and pose environmental issues. The effluent may contain dispersing agents.

- Poor on Natural Fibers: Not suitable for cotton, wool, or other natural fibers.

- Sublimation Concerns: Some disperse dyes can sublime at high temperatures, leading to shade change or staining of other materials during heat-setting or storage if not chosen carefully for their sublimation fastness.

- Hydrolysis: Certain disperse dyes, particularly those with ester groups, can hydrolyze under the dyeing conditions, leading to shade change or reduced fastness.

Disperse dyes are indispensable for the coloration of synthetic fibers, playing a critical role in producing the vast array of durable and vibrant synthetic textiles we encounter daily. Their unique application mechanism highlights the adaptability of dye chemistry to different fiber types.