Advanced Monitoring, Automation, and Digitalization in Water Treatment: Lecture 8

Overall Goal: To explore how modern technologies in monitoring, automation, and digitalization are transforming wastewater treatment plants, enhancing efficiency, ensuring compliance, and supporting sustainable water reuse in the textile industry.

8.1. The Shift to Smart Water Treatment

- Evolution of Plant Control: From manual operations and periodic lab tests to real-time, data-driven management.

- Why Digitalization? Discuss the drivers: increasing regulatory demands, need for greater efficiency, rising operational costs, growing complexity of treatment processes, and the desire for predictive capabilities.

- Benefits of Digital Transformation: Improved effluent quality consistency, reduced energy and chemical consumption, proactive maintenance, minimized human error, and enhanced decision-making.

8.2. Advanced Monitoring & Instrumentation: Real-time Insights

- Online Sensors & Analyzers:

- Crucial Parameters: Detail the importance of continuously monitoring key parameters like pH, Dissolved Oxygen (DO), Oxidation-Reduction Potential (ORP), Conductivity/TDS, Turbidity, Color, COD, and Ammonia/Nitrate.

- Types of Sensors: Briefly explain the working principles of common online sensors (e.g., optical DO sensors, ion-selective electrodes, UV-Vis spectrophotometers for COD/color).

- Benefits: Immediate detection of process upsets, continuous quality assurance for reused water, and optimized chemical dosing.

- Flow & Level Measurement: Discuss various technologies (e.g., ultrasonic, electromagnetic flowmeters) for accurate flow measurement at different stages, crucial for mass balance and chemical dosing.

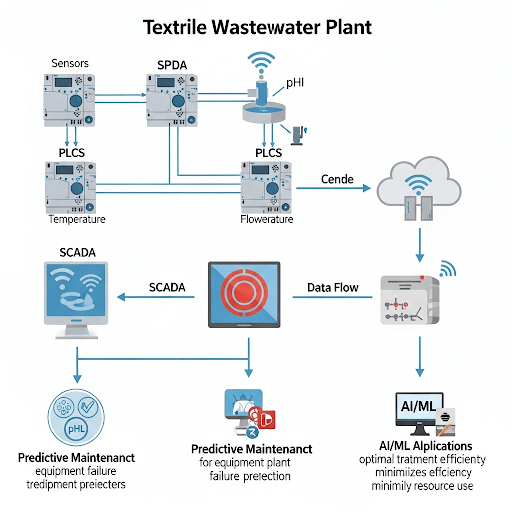

- Integration: How data from diverse sensors is collected and transmitted for central processing.

8.3. Automation & Control Systems: The Brains of the Plant

- Programmable Logic Controllers (PLCs): The workhorse of industrial automation. Explain how PLCs execute control logic based on sensor inputs and operator commands, managing pumps, valves, and chemical dosing.

- SCADA (Supervisory Control and Data Acquisition) Systems:

- Purpose: A centralized system that integrates all PLCs, sensors, and actuators. It provides a human-machine interface (HMI) for operators to monitor the entire plant, visualize data, and issue commands from a control room.

- Functions: Data logging, alarm management, historical trending, and remote control capabilities.

- Process Optimization & Control Loops:

- Feedback Control: How real-time sensor data is used to automatically adjust process parameters (e.g., increasing aeration based on DO levels, adjusting pH dosing based on effluent pH).

- Feed-forward Control: Predicting future conditions to make proactive adjustments.

- Advanced Control Strategies: Introduce concepts like fuzzy logic or model predictive control for more complex optimization scenarios.

8.4. Digitalization & The Future: Beyond Automation

- Data Management & Analytics:

- Data Historians: Storing vast amounts of operational data from sensors and PLCs.

- Data Visualization: Using dashboards and reports to make complex data understandable for decision-makers.

- Predictive Maintenance: Using historical data and machine learning algorithms to anticipate equipment failures before they occur, minimizing downtime and maintenance costs.

- Digital Twins:

- Concept: Creating a virtual, real-time replica of the physical water treatment plant. This digital model receives live data from sensors and can be used for simulation, optimization, and scenario planning without impacting the actual plant.

- Application: Testing new control strategies, training operators, and predicting process behavior.

- Artificial Intelligence (AI) & Machine Learning (ML) in Water Treatment:

- Applications: Anomaly detection, fault diagnosis, energy optimization, chemical dosage optimization, and forecasting influent loads.

- Benefits: Moving from reactive to proactive plant management, achieving higher levels of efficiency and resilience.

- Remote Operation & Cybersecurity: Discuss the capabilities and challenges of remotely operating plants, and the increasing importance of cybersecurity to protect critical infrastructure.

By the end of this final lecture, you’ll have a comprehensive understanding of how modern technology is not just supporting, but actively driving the future of textile wastewater treatment, ensuring sustainable and efficient water reuse.