A Detailed Lecture on the Chemistry of Nanotechnology in Textiles

Today, we’re going to delve into a fascinating and transformative field: the detailed chemistry of nanotechnology as applied to textiles. This isn’t just about making fabrics look good; it’s about fundamentally altering their properties at the molecular level to create materials that are smarter, stronger, cleaner, and more sustainable.

1. Introduction: Understanding the Nanoscale and Its Chemical Significance

Nanotechnology, at its core, is the manipulation of matter on an atomic, molecular, and supramolecular scale, typically in the range of 1 to 100 nanometers (nm). To grasp this scale, consider that a human hair is roughly 80,000 nanometers wide.

Why is this scale so critical from a chemical perspective?

- Increased Surface Area to Volume Ratio: As particles shrink to the nanoscale, their surface area dramatically increases relative to their volume. This means a much larger proportion of atoms are on the surface, making them far more chemically reactive and allowing for more efficient interactions with the surrounding environment (like textile fibers).

- Quantum Effects: At this minuscule size, materials can exhibit quantum mechanical phenomena. For example, semiconductors might change their band gap, leading to unique optical or electrical properties (like changing color or becoming more conductive).

- Unique Surface Chemistry: The increased surface energy and presence of active sites on nanoparticles dictate how they interact with textile polymers, influencing adhesion, bonding, and catalytic activities.

The chemistry of nanotechnology in textiles, therefore, involves understanding how these nanoscale properties can be leveraged to imbue conventional fibers with novel functionalities.

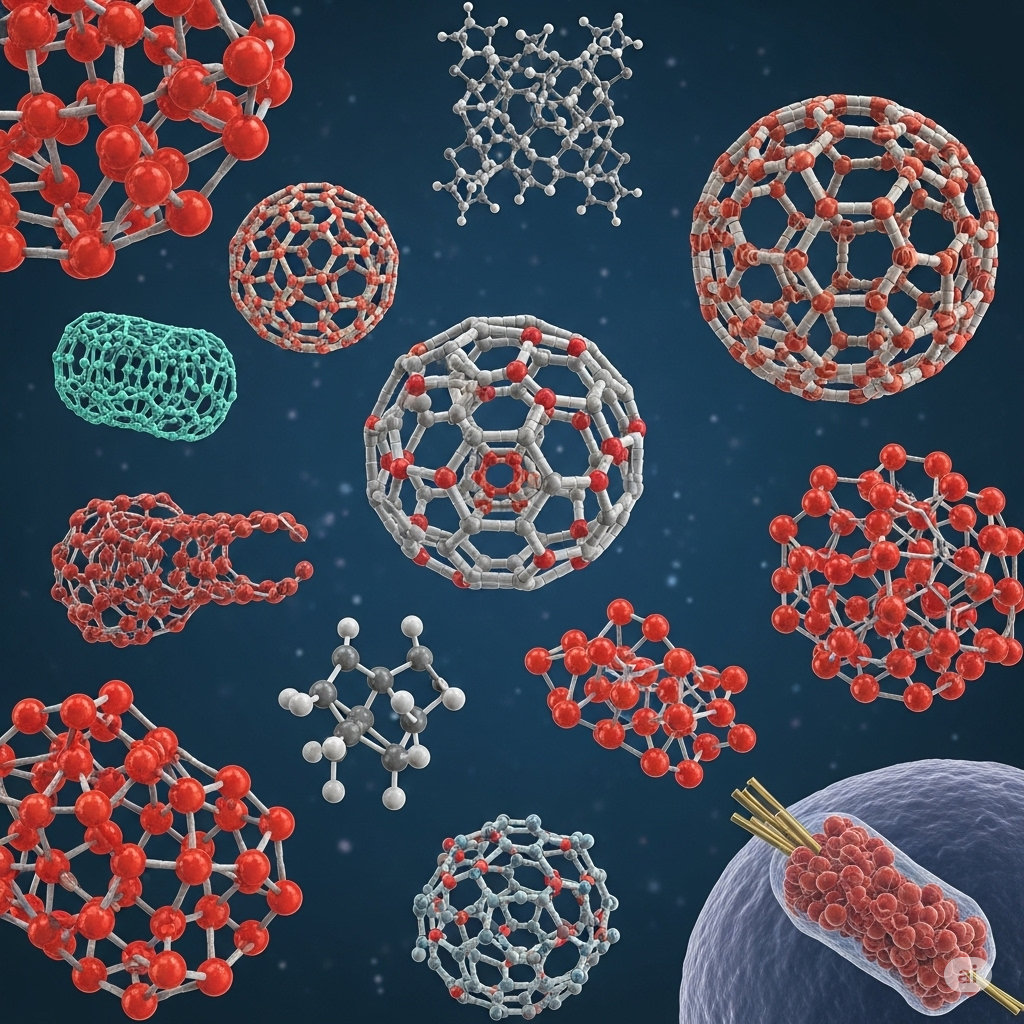

2. Key Nanomaterials and Their Chemical Characteristics for Textiles

Various nanomaterials are engineered for textile applications, each bringing specific chemical attributes:

- Metal Nanoparticles (AgNPs, TiO₂NPs, ZnONPs):

- Silver Nanoparticles (AgNPs): Synthesized typically through chemical reduction (e.g., using sodium borohydride or citrate to reduce silver salts like AgNO₃). Their antimicrobial action primarily stems from the controlled release of Ag⁺ ions. These ions are highly reactive, disrupting bacterial cell membranes, inhibiting enzyme activity, and interfering with DNA replication. Their high surface area enhances this ion release.

- Titanium Dioxide Nanoparticles (TiO₂NPs): Often produced via sol-gel methods or hydrothermal synthesis. TiO₂ is a semiconductor. When exposed to UV light (specifically UVA), it undergoes photocatalysis. The UV energy excites electrons from the valence band to the conduction band, generating electron-hole pairs. These react with water (H₂O) and oxygen (O₂) in the air to produce highly reactive hydroxyl radicals (⋅OH) and superoxide radicals (⋅O2−). These radicals effectively break down organic pollutants (dirt, odors, microbes) into simpler, harmless compounds like CO₂ and H₂O. This mechanism gives fabrics self-cleaning, antimicrobial, and UV-blocking properties.

- Zinc Oxide Nanoparticles (ZnONPs): Similar to TiO₂, ZnO also exhibits photocatalytic activity and broad-spectrum UV absorption, offering both UV protection and antimicrobial benefits. Its synthesis often involves precipitation or sol-gel methods.

- Carbon Nanomaterials (Carbon Nanotubes – CNTs, Graphene):

- Structure and Chemistry: CNTs are cylindrical allotropes of carbon with sp² hybridization, giving them exceptional strength and electrical conductivity. Graphene is a single layer of sp²-hybridized carbon atoms arranged in a 2D hexagonal lattice, possessing extraordinary strength, flexibility, and conductivity.

- Applications: Used for creating conductive textiles (e.g., for wearable electronics, antistatic fabrics), sensors, and significantly enhancing the mechanical strength of fibers when incorporated into composites. Their inert nature also makes them durable additives.

- Polymer Nanofibers:

- Synthesis: Primarily fabricated via electrospinning, where a polymer solution or melt is charged and drawn into extremely fine fibers (down to tens of nanometers) by an electric field.

- Chemistry/Benefit: The nanoscale diameter and high surface area of these fibers lead to enhanced filtration efficiency (e.g., for protective masks, air filters), improved strength-to-weight ratios, and potential for controlled drug release or advanced barrier properties. Common polymers include nylon, polyurethane, PVDF, and PLA.

- Silica Nanoparticles (SiO₂NPs):

- Chemistry: Typically synthesized via the Stöber process (hydrolysis and condensation of alkoxysilanes). Silica is chemically inert, non-toxic, and transparent.

- Applications: Crucial for creating superhydrophobic (water-repellent) surfaces. When combined with hydrophobic molecules (e.g., fluorocarbons or long-chain hydrocarbons), the nanoscale roughness created by silica particles dramatically increases the contact angle of water droplets, mimicking the Lotus effect. They also improve wrinkle resistance and flame retardancy when integrated into finishes.

- Nanoclays (e.g., Montmorillonite):

- Structure: Layered silicates that can exfoliate (separate into individual nanoscale layers) within polymer matrices.

- Applications: Primarily used as flame retardants and reinforcing agents. When heated, the nanoclay layers form a char barrier that insulates the underlying polymer, reducing fuel supply and heat transfer. Chemically, they can interact with polymer chains to improve dispersion and adhesion.

3. Methods of Nanomaterial Integration into Textile Substrates

The chemistry of integration dictates the durability and efficacy of the nano-finish.

- Dyeing and Finishing (Coating/Pad-Dry-Cure):

- Process: Nanoparticles are dispersed in a liquid medium and applied to the fabric using techniques like padding, spraying, or dip-coating. The fabric is then dried and often cured at high temperatures to chemically cross-link the nanoparticles or their binders to the fiber surface.

- Chemistry: This involves surface chemistry. The nanoparticles might form covalent bonds, hydrogen bonds, or even just strong van der Waals forces with the hydroxyl groups (in cellulose) or amide groups (in proteins/polyamides) on the fiber surface. Binders (e.g., acrylic or polyurethane resins) are often used to encapsulate and adhere the nanoparticles, forming a durable film. The chemical stability of the binder and its interaction with the fiber are crucial.

- Example: For hydrophobic finishes, fluorocarbon-based polymers with embedded silica nanoparticles are often applied, with the fluorocarbons aligning outwards to present a low surface energy.

- Incorporation During Fiber Spinning:

- Process: Nanoparticles are directly mixed with the polymer melt (for melt spinning) or solution (for wet/dry spinning) before the fiber is extruded.

- Chemistry: Requires careful control of nanoparticle dispersion within the polymer matrix to prevent agglomeration. Surface modification of nanoparticles (e.g., functionalization with silanes or polymers) might be necessary to improve their compatibility and chemical bonding with the polymer host. This creates a uniform dispersion throughout the fiber, leading to more durable and integrated functionalities.

- Surface Modification (e.g., Plasma Treatment):

- Process: Fabrics are exposed to a low-temperature plasma (ionized gas). This can chemically activate the fiber surface by introducing new functional groups (e.g., hydroxyl, carboxyl) or etching the surface to create nanoscale roughness.

- Chemistry: The activated surface provides more reactive sites for nanoparticles or their binders to attach, leading to stronger, more durable finishes without altering the bulk properties of the fiber.

4. Specific Chemical Mechanisms for Desired Properties

Let’s revisit some properties with a deeper chemical lens:

- Superhydrophobicity (Water Repellency):

- Chemistry: Achieved by creating a hierarchical rough surface (nanoscale structures combined with microscale roughness of fabric) and applying low surface energy compounds (typically fluorocarbons or waxes). Water droplets on such a surface have a contact angle greater than 150°, minimizing contact with the solid surface due to high surface tension. The nanostructures trap air pockets, preventing water from penetrating.

- Fluorocarbons: Contain C-F bonds, which are extremely nonpolar and have very low intermolecular forces, leading to low surface energy.

- Antimicrobial Action (e.g., Silver Nanoparticles):

- Chemistry:

- Ion Release: AgNPs release Ag⁺ ions.

- Membrane Disruption: Ag⁺ ions bind to and disrupt the cell wall and membrane of bacteria, increasing permeability and leading to leakage of cytoplasmic contents.

- Protein Denaturation: Ag⁺ ions react with thiol (-SH) groups in bacterial enzymes and proteins, denaturing them and inhibiting essential metabolic processes (e.g., respiration, nutrient transport).

- DNA Interaction: Ag⁺ ions can bind to DNA, inhibiting replication and leading to bacterial death.

- Mechanism of TiO₂: As mentioned, photocatalysis generates reactive oxygen species (ROS) like ⋅OH, which cause oxidative damage to microbial cells.

- Chemistry:

- UV Protection:

- Chemistry: TiO₂ and ZnO nanoparticles are semiconductor metal oxides. They absorb UV radiation across a broad spectrum due to their electronic band structure. When UV light hits the nanoparticles, it excites electrons, dissipating the energy and preventing it from reaching the skin or degrading the fabric. They also scatter UV light due to their size.

- Wrinkle Resistance:

- Chemistry: Traditional methods used formaldehyde-based cross-linking agents. Modern approaches focus on formaldehyde-free cross-linkers (e.g., citric acid derivatives, polycarboxylic acids). These agents react with the hydroxyl groups of cellulose (in cotton) to form covalent bonds, cross-linking adjacent cellulose chains. This ‘locks’ the fibers in place, preventing them from shifting and forming creases. The challenge is achieving effective cross-linking without compromising fabric strength.

5. Challenges and Future Directions

Despite immense progress, challenges remain:

- Durability: Ensuring that nano-finishes withstand repeated washing and wear without losing functionality (leaching of nanoparticles, degradation of binders). This is a primary focus of current chemical research in the field.

- Safety and Environmental Impact: Thoroughly assessing the ecotoxicity and human health effects of nanoparticles, especially their release into wastewater during washing. Responsible design and lifecycle assessment are critical.

- Cost-Effectiveness: Scaling up nanomaterial synthesis and integration processes to be economically viable for mass production.

- Uniformity: Ensuring an even distribution of nanoparticles on or within fibers for consistent performance.

- Multifunctionality: Developing single treatments that can impart multiple properties simultaneously (e.g., self-cleaning, antimicrobial, and UV protection).

- Smart Textiles: Further integration of conductive nanomaterials for truly interactive and energy-harvesting fabrics, which will rely heavily on advances in organic and inorganic nanomaterial chemistry.

The chemistry of nanotechnology in textiles is a dynamic and exciting frontier. It promises to transform how we interact with our clothes, making them not just coverings, but active partners in comfort, health, and sustainability. As chemical synthesis and integration methods become more refined, we can expect to see an even broader range of “smart” and high-performance fabrics in the near future.

Thank you.

Lecture: The Detailed Chemistry of Nanotechnology in Textiles

Good morning/afternoon, everyone. Today, we’re going to delve into a fascinating and rapidly expanding field: the detailed chemistry behind nanotechnology’s revolutionary impact on textiles. We’ll explore how manipulating matter at the nanoscale, typically 1 to 100 nanometers, allows us to imbue fabrics with extraordinary new properties, moving them beyond traditional functions into the realm of “smart” and “functional” materials.

I. Introduction to Nanochemistry and Textile Interaction

At the heart of nanotechnology in textiles lies nanochemistry. This is the study of chemical processes and reactions that occur at the nanoscale, where materials exhibit unique behaviors due to:

- High Surface Area to Volume Ratio: As particle size decreases, the proportion of atoms on the surface relative to those in the bulk increases dramatically. This means more reactive sites are available for chemical interactions.

- Quantum Effects: At extremely small scales, quantum mechanical phenomena become significant, altering properties like electrical conductivity, optical absorption, and reactivity.

- Surface Energy and Interfacial Phenomena: Nanoparticles possess high surface energy, making them highly reactive and prone to aggregation, but also excellent for surface modification and adhesion.

When these nanoscale materials interact with textile fibers (which are themselves often in the micrometer to nanometer range in terms of individual fibrils), the opportunities for precise modification of fabric properties are immense.

II. Key Nanomaterials and Their Chemical Basis in Textiles

Various types of nanomaterials are engineered and integrated into textile substrates. Let’s examine the chemistry of some of the most prominent ones:

A. Metal and Metal Oxide Nanoparticles:

- Silver Nanoparticles (AgNPs):

- Synthesis: Often synthesized via chemical reduction methods, where silver salt precursors (e.g., silver nitrate, AgNO$_3$) are reduced in the presence of reducing agents (e.g., sodium borohydride, citrate, plant extracts) and stabilizing agents.

- Antimicrobial Mechanism: This is a key application. AgNPs release Ag$^+$ ions. These ions:

- Bind to cell membranes: Disrupting their integrity, leading to leakage of cellular contents.

- Enter bacterial cells: Interacting with sulfur-containing proteins and phosphorus-containing DNA, interfering with cell respiration, enzyme activity, and DNA replication.

- Generate Reactive Oxygen Species (ROS): Leading to oxidative stress and cellular damage.

- Application in Textiles: Impregnated into fibers or coated onto fabric surfaces using binder chemicals, often seen in sportswear, medical textiles, and odor-resistant socks.

- Titanium Dioxide (TiO$_2$) Nanoparticles:

- Synthesis: Commonly prepared via sol-gel methods, hydrothermal synthesis, or chemical vapor deposition. Anatase is the most photocatalytically active crystalline phase.

- Applications:

- UV Protection: TiO$_2$ nanoparticles efficiently absorb and scatter UV radiation due to their wide bandgap, offering excellent UV blocking properties. This is a physical and electronic interaction.

- Self-Cleaning (Photocatalysis): This is a remarkable chemical property. When exposed to UV light (e.g., sunlight), TiO$_2$ acts as a photocatalyst. It absorbs photons, leading to the excitation of electrons from the valence band to the conduction band, generating electron-hole pairs (e− and h+). These highly reactive species react with oxygen and water molecules on the fabric surface to produce powerful oxidizing agents like hydroxyl radicals ($\cdot$OH) and superoxide radicals (O2⋅−). These radicals then chemically break down organic dirt, pollutants, and odors into simpler, easily removable compounds (e.g., CO$_2$, H$_2$O).

- Application in Textiles: Coatings for outdoor fabrics, curtains, and self-cleaning apparel.

- Zinc Oxide (ZnO) Nanoparticles:

- Synthesis: Similar to TiO$_2$, using methods like sol-gel or precipitation.

- Applications: Possess both UV-blocking (similar mechanism to TiO$_2$) and antimicrobial properties (Zn$^{2+}$ ions disrupt cell membranes and protein function).

B. Carbon Nanomaterials:

- Carbon Nanotubes (CNTs) and Graphene:

- Structure: CNTs are cylindrical nanostructures of carbon atoms, while graphene is a single layer of carbon atoms arranged in a 2D hexagonal lattice.

- Properties & Chemistry: Both exhibit exceptional electrical conductivity, high thermal conductivity, and immense tensile strength due to their unique sp$^2$ hybridized carbon bonding.

- Applications:

- Conductive Textiles: Incorporated to create electrically conductive fabrics for wearable electronics, sensors (e.g., strain sensors, temperature sensors), and heating elements. The delocalized π-electrons facilitate electron transport.

- Enhanced Mechanical Strength: Composites with CNTs or graphene can significantly improve the mechanical strength, stiffness, and durability of fibers and fabrics.

- Integration: Often dispersed in polymer solutions and then electrospun, melt-spun, or coated onto existing fabrics.

C. Silica Nanoparticles (SiO$_2$):

- Synthesis: Commonly produced via the sol-gel process from alkoxides (e.g., tetraethyl orthosilicate, TEOS) undergoing hydrolysis and condensation.

- Applications (Superhydrophobicity): Silica nanoparticles are critical for creating highly water-repellent (superhydrophobic) surfaces.

- Mechanism: When combined with low surface energy materials (like fluorocarbons or alkyl silanes), silica nanoparticles create a rough, hierarchical surface topography at the nanoscale. This rough surface traps air pockets between the water droplet and the fabric, significantly reducing the contact area between the liquid and the solid (Wenzel and Cassie-Baxter models). Water droplets then bead up with very high contact angles (>150∘) and roll off easily, carrying dirt particles with them (Lotus effect). The chemical bonds formed between silane coupling agents and the fabric surface ensure durability.

D. Polymeric Nanofibers:

- Formation: Primarily produced via electrospinning, where a polymer solution or melt is subjected to a high-voltage electric field. The electrostatic forces overcome surface tension, drawing out a fine jet that solidifies into continuous nanofibers with diameters typically ranging from tens to hundreds of nanometers.

- Properties: Possess extremely high surface area-to-volume ratio, high porosity, and flexibility.

- Applications: Filtration (air and water), protective clothing (barrier fabrics), wound dressings, and smart textiles due to their ability to incorporate other functional nanoparticles.

E. Nanoclays:

- Structure: Layered mineral silicates (e.g., montmorillonite) with layers typically 1 nm thick.

- Applications (Flame Retardancy, Barrier Properties):

- Mechanism: When dispersed in polymer matrices (e.g., during fiber spinning), nanoclays form a tortuous path for volatile degradation products during combustion, acting as a barrier. They can also promote char formation, which protects the underlying material from heat and oxygen. Chemically, they can interact with polymer chains to improve thermal stability.

- Benefits: Reduce flammability, smoke production, and heat release.

III. Methods of Nanomaterial Integration into Textiles

The effectiveness and durability of nano-functionalized textiles depend heavily on how the nanomaterials are integrated.

- Ex-situ Methods (Surface Coating/Finishing):

- Pad-Dry-Cure: Fabric is immersed in a bath containing nanoparticles (often dispersed with binders or cross-linking agents), then padded to remove excess liquid, dried, and finally cured (heated) to fix the nanoparticles to the fiber surface via chemical bonding (e.g., covalent bonds with functional groups on fibers), physical adsorption, or polymer entrapment.

- Spray Coating: Nanoparticle dispersions are sprayed onto the fabric.

- Layer-by-Layer (LbL) Assembly: Involves alternating deposition of oppositely charged polyelectrolytes and nanoparticles onto the fabric surface, building up a multilayered coating through electrostatic interactions. Offers precise control over film thickness and composition.

- Plasma Treatment: Surface activation of textile fibers using plasma creates reactive sites (e.g., free radicals, hydroxyl groups) that promote better adhesion and bonding of subsequently applied nanoparticles, making finishes more durable.

- In-situ Methods (Incorporation into Fibers):

- Melt Spinning/Wet Spinning: Nanoparticles are homogeneously dispersed into the polymer melt or solution before the fibers are formed. This embeds the nanoparticles within the fiber matrix, offering superior durability against washing and abrasion. The challenge lies in ensuring good dispersion and preventing aggregation, which can weaken the fiber.

- Graft Polymerization: Monomers are polymerized directly onto the fiber surface in the presence of nanoparticles, effectively grafting new polymer chains that contain or bind the nanoparticles.

IV. Challenges and Future Directions

Despite the immense potential, the nanochemistry of textiles faces several challenges:

- Durability of Finishes: Ensuring that nano-finishes remain effective after multiple washing cycles is a major challenge. Chemical bonding strategies are key to improving wash fastness.

- Safety and Environmental Impact: The potential release of nanoparticles during washing, wear, or disposal is a significant concern. Research focuses on “green synthesis” of nanoparticles (e.g., using plant extracts) and ensuring their immobilization.

- Cost-Effectiveness: Scaling up laboratory processes for industrial production remains a hurdle for many advanced nano-textile applications.

- Uniformity and Aggregation: Achieving uniform dispersion of nanoparticles within fibers or on surfaces, and preventing their aggregation, is critical for consistent performance.

- Recycling and End-of-Life: Developing sustainable recycling methods for nano-modified textiles is an emerging area of research.

The future of nanochemistry in textiles is bright, promising a new generation of intelligent fabrics that can respond to stimuli, monitor health, generate energy, and offer unprecedented levels of comfort and protection. As our understanding of nanoscale phenomena deepens, so too will our ability to precisely engineer textiles for a vast array of sophisticated applications.