Fiber & Other Material Recovery from Textile Wastewater: Lecture 4

Overall Goal: To identify the types of solid materials (especially fibers) present in textile wastewater, understand the technologies for their efficient recovery, and evaluate their potential for reuse or valorization.

4.1. The Solid Waste Challenge in Textile Wastewater

- Sources of Solids: Discuss where solid materials originate in textile wet processing, including:

- Loose Fibers/Lint: From washing, scouring, and dyeing processes. These can be significant in volumes.

- Fabric Scraps/Trimmings: Though less common in the main wastewater stream, smaller pieces can enter.

- Inorganic Particulates: Sand, dirt from raw materials or process water.

- Sludge Solids: While we covered biogas from organic sludge, there are also inert solids.

- Impact of Solids on Wastewater Treatment: Explain how high concentrations of suspended solids and fibers can:

- Increase COD/BOD (if organic).

- Cause clogging in pumps, pipes, and heat exchangers.

- Lead to fouling of membranes in advanced treatment.

- Increase sludge volume and disposal costs.

- Interfere with biological treatment processes.

- The Opportunity: Recovering these materials can reduce the load on the treatment plant, prevent equipment damage, and provide a potential raw material for other industries.

4.2. Technologies for Fiber & Material Recovery

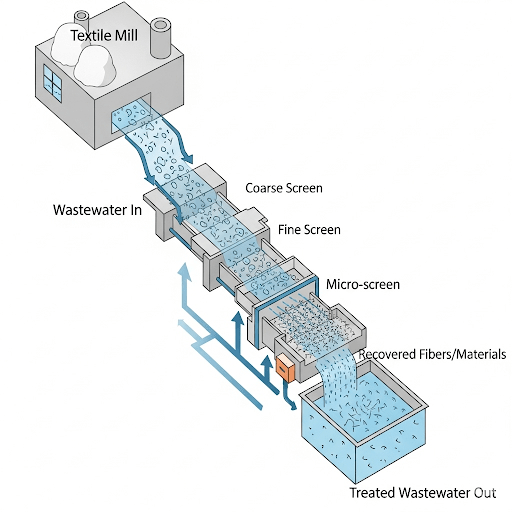

- Screening & Filtration:

- Coarse Screens: For large debris and lint, often at the primary collection points.

- Fine Screens/Micro-screens: Rotary drum screens or vibrating screens with finer mesh sizes to capture smaller fibers and suspended solids.

- Dissolved Air Flotation (DAF): Can be used to separate suspended solids and some lighter fibers by floating them to the surface with air bubbles.

- Gravity Settlers/Clarifiers: For heavier suspended solids.

- Centrifugation: Used for separating solids from liquids based on density differences, especially for finer suspended particles.

- Hydrocyclones: Devices that use centrifugal force to separate particles from a liquid based on density, often used for smaller, denser particles.

- Flotation (Advanced): Specific flotation techniques designed to separate fibrous material from wastewater.

- Membrane Filtration (Pre-treatment): While primarily for water purification, membrane systems (like MF or UF) can act as highly efficient filters for solids when used as pre-treatment.

4.3. Valorization and Reuse of Recovered Materials

- Fiber-to-Fiber Recycling:

- Challenges: Mixed fiber types (cotton, polyester, blends), presence of dyes and chemicals.

- Opportunities: If clean enough, recovered fibers can be used for non-woven fabrics, insulation, soundproofing, or even blended into new yarns. Discuss the need for sorting and processing.

- Cellulose Recovery: For cotton-based fibers, cellulose can potentially be recovered and used in other industries.

- Composting/Soil Amendment: If fibers are natural (cotton, wool) and not heavily contaminated, they can be composted.

- Energy Recovery (Solid Fuel): If other recovery options are not viable, dried fibrous waste can be used as a supplementary fuel in industrial boilers (e.g., cement kilns, textile mill boilers, if permissible and environmentally sound).

- Challenges in Valorization: Market demand for recovered materials, quality consistency, contamination levels, and the cost of further processing (e.g., cleaning, sorting).

4.4. Case Studies & Best Practices in Solid Material Recovery

- Real-World Examples: Highlight textile mills or recycling facilities that have successfully implemented fiber or solid material recovery, detailing the technologies used, the quantity of material recovered, and its end-use.

- Economic & Environmental Benefits: Discuss the reduction in waste disposal costs, potential revenue from recovered materials, and overall reduction in environmental footprint.

- Integrated Systems: How solid recovery integrates with overall wastewater treatment and other resource recovery efforts.

By the end of this lecture, you’ll appreciate the hidden value in the solid waste streams of textile wastewater and understand the methods to capture and potentially repurpose these materials, contributing to a more circular textile industry.