Chemical Recovery in Textile Wet Processing: Lecture 2

Overall Goal: To identify key chemicals used in textile wet processing that are amenable to recovery, understand the technologies and principles behind their reclamation, and assess the economic and environmental benefits of chemical reuse.

2.1. The Chemical Footprint of Textile Production

- Review of Chemical Use: Briefly recap the types and quantities of chemicals typically used in textile wet processing (e.g., caustic soda, acids, sizing agents, dyes, salts).

- Challenges of Chemical Discharge: Discuss the environmental impact of these chemicals if discharged (e.g., high pH, high COD, toxicity, salinity) and the costs associated with their fresh purchase.

- The Case for Chemical Recovery: Emphasize that chemical recovery offers dual benefits: cost savings from reduced fresh chemical purchase and environmental gains from lower chemical discharge and reduced raw material extraction.

2.2. Key Chemicals and Their Recovery Potential

We’ll focus on specific high-volume or high-value chemicals commonly targeted for recovery:

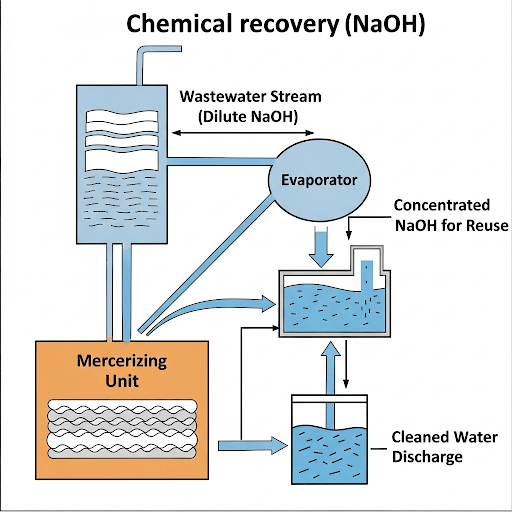

- Caustic Soda (NaOH) Recovery:

- Source: Primarily from mercerizing and scouring processes, where significant amounts of caustic soda are used and then discharged.

- Recovery Principles:

- Evaporation: Concentrating dilute caustic solutions using multi-effect evaporators (MEE) or mechanical vapor recompression (MVR) to recover a concentrated caustic solution for reuse.

- Membrane Filtration: Using specific nanofiltration or reverse osmosis membranes to separate caustic from impurities.

- Benefits: Substantial cost savings, reduced effluent alkalinity, and decreased fresh caustic consumption.

- Indigo Dye Recovery:

- Source: From denim dyeing processes, where a significant portion of dye remains in the wastewater (spent dye baths, wash water).

- Recovery Principles:

- Coagulation/Flocculation: Using chemical agents to precipitate the dye, followed by sedimentation.

- Membrane Filtration: Microfiltration or ultrafiltration to separate dye particles.

- Adsorption: Using activated carbon or other adsorbents to capture dissolved dye.

- Benefits: Reduced dye consumption, lower effluent color, and decreased COD.

- Sizing Agent Recovery:

- Source: From desizing processes, where sizing agents (e.g., PVA – polyvinyl alcohol, starch) are removed from the warp yarns.

- Recovery Principles:

- Ultrafiltration: Separating high molecular weight sizing agents from water and smaller impurities.

- Precipitation: For certain types of sizing agents.

- Benefits: Reduced fresh sizing agent purchase, lower COD load on wastewater treatment, and potential for direct reuse in sizing baths.

- Salt Recovery:

- Source: From reactive dyeing processes, where large quantities of salt are used as an electrolyte.

- Recovery Principles: Highly challenging due to mixed impurities, but can involve crystallization (in conjunction with ZLD efforts) or membrane separation.

- Benefits: Potential for reuse of pure salt, reduced effluent salinity.

2.3. Technologies and Integration for Chemical Recovery Systems

- Evaporation Technologies: Detailed look at MEE and MVR systems, including energy requirements, heat integration, and challenges (e.g., scaling, corrosion).

- Membrane Technologies: Discuss specific membrane types (UF, NF, RO) tailored for chemical separation, emphasizing membrane fouling control and cleaning.

- Process Design Considerations:

- Waste Stream Segregation: Importance of separating specific high-value or high-concentration chemical streams from the general wastewater.

- Purity Requirements: Ensuring the recovered chemical meets the purity standards for its intended reuse application.

- Integration with Overall Plant: How recovery systems fit into the existing chemical handling and wastewater treatment infrastructure.

2.4. Economic and Environmental Benefits of Chemical Recovery

- Quantifying Cost Savings: Detailed analysis of reduced chemical purchase costs, lower disposal/discharge fees, and potential for new revenue streams.

- Environmental Impact Reduction: Decreased consumption of virgin raw materials, lower energy usage for chemical production, and significant reduction in pollutant load (COD, color, salinity, pH).

- Case Studies: Examples of textile mills that have successfully implemented caustic or indigo recovery systems, showcasing their financial and environmental gains, and the challenges they overcame.

By the end of this lecture, you’ll have a thorough understanding of the technical and economic feasibility of recovering valuable chemicals from textile wastewater, positioning it as a key strategy for sustainable textile manufacturing.