Deeper Dives & Future Frontiers: Lecture 11

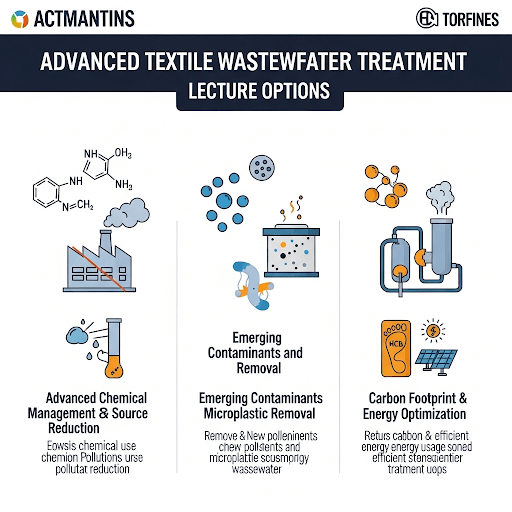

Option A: Advanced Chemical Management and Source Reduction in Textile Wet Processing

This lecture would shift focus upstream, examining how managing chemicals at their source within textile processes can significantly reduce the pollution load on wastewater treatment plants, making reuse even more efficient.

- Goal: To understand how proactive chemical management strategies and source reduction techniques in textile wet processing can minimize pollution, optimize wastewater treatment, and enhance water reuse potential.

- Key Topics:

- The Chemical Footprint of Textiles: Overview of common chemicals used in dyeing, printing, and finishing, and their environmental impact.

- Restricted Substances Lists (RSLs) and Manufacturing Restricted Substances Lists (MRSLs): A deeper dive into how these lists (e.g., ZDHC MRSL) guide the selection of safer chemicals.

- Best Available Technologies (BAT) for Chemical Application: Exploring techniques that minimize chemical consumption (e.g., foam dyeing, digital printing, optimized bath ratios).

- Pollution Prevention at Source: Strategies like process optimization, good housekeeping, and waste segregation to prevent chemicals from entering the wastewater stream.

- Dye Fixation and Washing-Off Optimization: How improving dye uptake and reducing excess dye on fabric can lead to cleaner wastewater.

- Chemical Recovery & Reuse: Exploring techniques for recovering valuable chemicals directly from process baths (e.g., caustic recovery from mercerizing).

Option B: Emerging Contaminants and Microplastic Removal in Textile Wastewater

This lecture would address the cutting-edge challenge of pollutants that traditional treatment systems often miss, which are becoming increasingly important for environmental protection and human health.

- Goal: To identify emerging contaminants and microplastics in textile wastewater, understand their environmental and health impacts, and explore advanced treatment technologies for their removal.

- Key Topics:

- Definition of Emerging Contaminants (ECs): Pharmaceuticals, personal care products, endocrine-disrupting chemicals, and other micropollutants.

- Sources in Textile Wastewater: Specific ECs that originate from textile auxiliaries, dyes, and finishing agents.

- Microplastics: Origin of microfibers from textile washing, their prevalence in wastewater, and environmental fate.

- Impact of ECs and Microplastics: Ecological effects (e.g., endocrine disruption in aquatic life), potential human health concerns, and their persistence in the environment.

- Advanced Removal Technologies:

- AOPs (Revisited): More advanced applications for EC degradation.

- Membrane Technologies: RO and specialized NF for EC removal.

- Advanced Adsorption: Novel adsorbents beyond activated carbon.

- Bio-filtration & Bioreactors: Specialized microbial communities for EC breakdown.

- Microplastic Filtration: Technologies specifically designed to capture microfibers.

- Challenges in Detection and Regulation: The difficulties in monitoring ECs and microplastics, and the absence of clear regulatory standards.

Option C: Carbon Footprint and Energy Optimization in Textile Wet Processing & Water Treatment

This lecture would integrate our knowledge of water treatment with the broader sustainability goal of reducing the carbon footprint of the textile industry, focusing on energy.

- Goal: To analyze the energy consumption associated with textile wet processing and wastewater treatment, and to explore strategies for energy optimization and greenhouse gas (GHG) emission reduction.

- Key Topics:

- Energy Consumption in Wet Processing: Heating of dye baths, drying, curing – significant energy users.

- Energy Consumption in Wastewater Treatment: Aeration, pumping, membrane operations – major contributors to treatment plant OpEx.

- Carbon Footprint of Textile Industry: Understanding direct and indirect GHG emissions.

- Energy Audit and Optimization: Methodologies for identifying energy hotspots and implementing efficiency measures.

- Heat Recovery Systems: Detailed exploration of technologies to recover heat from hot effluent and exhaust gases for reuse in process baths or space heating.

- Renewable Energy Integration: Feasibility of solar, wind, or biomass energy for powering textile mills and wastewater treatment plants.

- Biogas Production from Anaerobic Digestion: Utilizing sludge to generate renewable energy.

- Carbon Sequestration Opportunities: Potential within the textile wastewater management context.