Economic Viability & Sustainability Assessment of Water Reuse Systems: Lecture 7

Overall Goal: To evaluate the financial feasibility and environmental benefits of implementing integrated textile wastewater treatment and reuse systems, providing tools and frameworks for decision-making.

7.1. Beyond Compliance: The Economic Imperative for Water Reuse

- The Cost of “Business as Usual”: Review the rising costs of freshwater purchase, escalating effluent discharge fees, and potential penalties for non-compliance.

- Drivers for Investment:

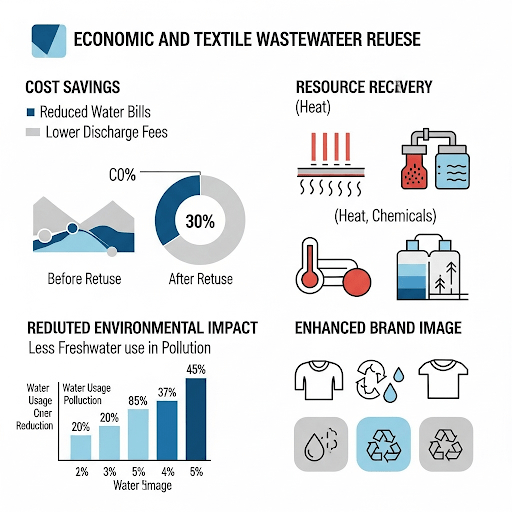

- Cost Savings: Reduced operational costs from lower freshwater consumption and discharge volumes.

- Resource Recovery: Potential for heat recovery from hot effluent, or even chemical recovery in some specific processes.

- Risk Mitigation: Reduced exposure to water scarcity, price volatility, and tightening environmental regulations.

- Brand Value & CSR: Enhanced corporate reputation, meeting sustainability goals, and appealing to environmentally conscious consumers.

- The “Triple Bottom Line”: Introduce the concept of People, Planet, Profit – how water reuse contributes to all three.

7.2. Financial Analysis: Making the Business Case

- Capital Expenditure (CapEx):

- What it Includes: Costs associated with design, equipment purchase (tanks, pumps, membranes, instruments), civil works, installation, and commissioning of the treatment plant.

- Factors Influencing CapEx: Scale of the plant, complexity of chosen technologies (e.g., RO vs. less advanced systems), land availability, and site-specific conditions.

- Operational Expenditure (OpEx):

- What it Includes: Ongoing costs such as energy consumption (for pumps, aerators, heating/cooling), chemical consumption (coagulants, pH adjusters, membrane cleaning chemicals), labor, maintenance, spare parts, and most importantly, sludge disposal costs and brine management costs.

- Strategies for OpEx Reduction: Energy efficiency measures, chemical recovery, automation to reduce labor, and optimized maintenance schedules.

- Cost-Benefit Analysis:

- Methodology: A systematic approach to compare the total costs of implementing a reuse system against its total benefits over a project’s lifetime.

- Key Metrics:

- Net Present Value (NPV): The present value of all future cash flows (inflows minus outflows). A positive NPV indicates a profitable investment.

- Internal Rate of Return (IRR): The discount rate at which the NPV of all cash flows from a particular project equals zero. A higher IRR is generally preferred.

- Payback Period: The time it takes for the cumulative benefits (savings) to equal the initial investment. A shorter payback period is often desired.

- Financial Models: Briefly discuss simple spreadsheet models to calculate these metrics, often involving assumptions about future water prices, energy costs, and regulatory changes.

7.3. Sustainability Assessment: Quantifying Environmental Benefits

- Water Accounting & Auditing:

- Purpose: Systematic tracking of water inputs, consumption, losses, and discharges within the textile facility. This forms the baseline for identifying savings and measuring reuse effectiveness.

- Key Performance Indicators (KPIs): Water intensity (liters of water per kg of fabric), reuse rate (percentage of treated effluent reused).

- Quantifying Environmental Impacts:

- Reduced Freshwater Abstraction: Direct savings in water resources.

- Reduced Wastewater Discharge: Less pollution released to the environment, potentially lower discharge fees.

- Reduced Energy Consumption (Indirect): Lower energy use for pumping fresh water over long distances, and less energy for wastewater treatment at a municipal level.

- Lower Carbon Footprint: Associated with reduced energy consumption and chemical use for traditional treatment.

- Introduction to Life Cycle Assessment (LCA):

- Concept: A holistic methodology to assess the environmental impacts associated with all stages of a product’s or process’s life cycle (e.g., from raw material extraction to disposal).

- Application in Reuse: How LCA can be used to compare the overall environmental impact of a conventional treatment-and-discharge system versus an integrated reuse system. It helps avoid “burden shifting” (e.g., solving water scarcity but increasing energy use significantly).

7.4. Regulatory Frameworks & Incentives

- Government Policies & Regulations (with Pakistan Context): Discuss how increasing environmental regulations (e.g., NEQS in Pakistan) are pushing industries towards better treatment and reuse.

- Incentives for Water Reuse:

- Financial Incentives: Subsidies, tax breaks, low-interest loans, or grants from governments or international development banks for adopting sustainable water practices.

- Non-Financial Incentives: Recognition programs, easier permitting processes for compliant industries.

- Corporate Social Responsibility (CSR) & Market Demand: The growing pressure from brands and consumers for sustainable textile production, making water reuse a market differentiator.

By the end of this lecture, you’ll be equipped to not only understand the technical aspects of water reuse but also to articulate its compelling economic and environmental benefits, crucial for driving adoption in the textile industry.