Textile Pretreatment: Lecture #7 – Heat Setting

Welcome back to our series on Textile Pretreatment! We’ve covered the crucial wet processes for cotton, including greige fabric inspection, singeing, desizing, scouring, bleaching, and mercerization. Now, we turn our attention to a critical physical pretreatment, primarily for synthetic thermoplastic fibers like polyester, nylon, and acetate: Heat Setting.

1. Introduction to Heat Setting

Heat Setting is a thermal treatment process that stabilizes the dimensions and shape of thermoplastic textile materials (fibers, yarns, fabrics) by subjecting them to heat for a controlled duration. This process is essential because thermoplastic fibers, when heated, can deform and retain that deformation upon cooling. Heat setting permanently “sets” the desired molecular arrangement and fabric dimensions, making them resistant to subsequent changes due to heat, washing, or mechanical stress.

Why is Heat Setting Essential for Synthetic Fibers?

Synthetic fibers like polyester are made from long polymer chains. During manufacturing (spinning, drawing, weaving/knitting), these chains are stretched and oriented, creating internal stresses and a tendency to shrink or distort when exposed to heat or moisture. Heat setting alleviates these internal stresses and “locks in” the desired dimensions and properties.

- Dimensional Stability: The primary reason for heat setting. It provides excellent resistance to shrinkage and stretching during subsequent wet processing (dyeing, washing), pressing, and consumer use. Without heat setting, a polyester garment might shrink significantly after the first wash.

- Crease Resistance and Recovery: Improves the fabric’s ability to resist creasing during wear and to recover from wrinkles.

- Improved Handle (Feel): Can influence the stiffness, softness, and drape of the fabric.

- Enhanced Dyeing Properties: While not directly aiding dye uptake like mercerization, heat setting ensures uniform dye penetration by stabilizing the fiber structure and preventing uneven shrinkage during dyeing, which could lead to unlevelness. It also improves fastness by ensuring dye molecules are held securely within a stable structure.

- Lustre and Surface Smoothness: Can affect the surface appearance, contributing to a smoother feel and controlled luster.

- Relief of Internal Stresses: Reduces the inherent tension within the polymer chains, leading to a more relaxed and stable material.

2. The Chemistry and Mechanism of Heat Setting

Heat setting is a physical process that involves changes in the morphology (physical structure) of the polymer within the fiber.

- Amorphous and Crystalline Regions: Synthetic fibers contain both highly ordered crystalline regions and disordered amorphous regions. The internal stresses are largely concentrated in the amorphous regions.

- Glass Transition Temperature (Tg): Thermoplastic polymers have a glass transition temperature (Tg), above which their amorphous regions become more mobile and flexible. For polyester, Tg is around 70−80∘C.

- Melting Point (Tm): Polymers also have a melting point (Tm), above which their crystalline regions break down, and the fiber loses its shape. For polyester, Tm is around 250−260∘C.

- Mechanism: During heat setting, the fabric is heated to a temperature above its glass transition temperature (Tg) but below its melting point (Tm). At this elevated temperature:

- The polymer chains in the amorphous regions gain sufficient energy to become more mobile.

- Internal stresses within the fiber are relaxed as the chains rearrange into a more stable, relaxed configuration.

- New, more stable physical bonds (e.g., hydrogen bonds, Van der Waals forces) form between the polymer chains.

- If tension is applied, the polymer chains are aligned in the desired dimensions.

- Upon rapid cooling, these new arrangements are “frozen” or “locked in,” making them permanent. The fibers then resist further changes in dimension when exposed to temperatures below the setting temperature.

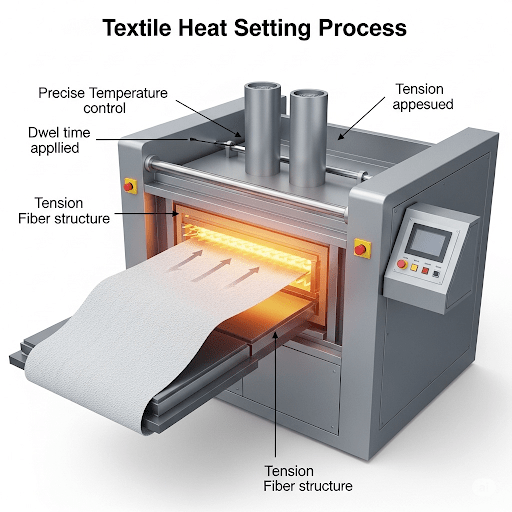

3. The Heat Setting Process

Heat setting is almost always performed on a stenter (tenter) frame for fabrics, where precise control over temperature, time, and tension is possible.

Key Stages in a Stenter for Heat Setting:

- Fabric Entry: The fabric enters the stenter frame, often guided by rollers.

- Edge Guiding and Pinning/Clipping: The fabric edges are precisely guided and pinned onto endless chains (pin stenter) or gripped by clips (clip stenter). This holds the fabric at a precise width, allowing for controlled stretching or overfeeding as required.

- Heating Chambers: The pinned/clipped fabric passes through a series of heated chambers.

- Heating Medium: Typically hot air (heated by gas or steam), or sometimes infrared heaters.

- Temperature: Controlled precisely based on fiber type and desired effect (e.g., 180−220∘C for polyester).

- Time: The dwell time in the hot chambers is critical and depends on temperature, fabric thickness, and desired result (e.g., 30-90 seconds).

- Cooling Zone: After exiting the heating chambers, the fabric is rapidly cooled, usually by forced ambient air. This sudden cooling “sets” the molecular rearrangement.

- Fabric Exit: The fabric is unpinned/unclipped and smoothly delivered.

4. Factors Influencing Heat Setting Efficiency

- Temperature: The most critical factor. Higher temperatures result in more complete setting but also carry a higher risk of fiber degradation (yellowing, strength loss) if exceeding optimal limits.

- Time: Sufficient dwell time is needed for the polymer chains to relax and rearrange. Longer times at lower temperatures can sometimes achieve similar results to shorter times at higher temperatures, but with less risk.

- Tension/Overfeed:

- Widthwise Tension: Controlled by the width setting of the stenter.

- Lengthwise Tension (Overfeed/Underfeed): Controlled by the speed difference between fabric entry and the stenter chains. Overfeeding allows for relaxation shrinkage, while underfeeding stretches the fabric. This determines the final fabric dimensions and density.

- Fiber Type: Each thermoplastic fiber has its specific optimal heat-setting temperature range.

- Moisture Content: The presence of moisture can sometimes assist in the setting process (e.g., steam setting for nylon), as water can act as a plasticizer.

- Air Circulation: Uniform airflow within the stenter chambers is essential for even heat transfer across the fabric width.

5. Types of Heat Setting

- Pre-setting: Heat setting performed before wet processing (scouring, dyeing). This is common for polyester to achieve initial dimensional stability, prevent creasing in wet processes, and ensure level dyeing.

- Post-setting: Heat setting performed after dyeing. This is done to achieve final dimensional stability and can also enhance dye fastness for certain dyes by promoting better dye aggregation within the fiber. However, post-setting can sometimes cause dye migration or sublimation for dyes with poor sublimation fastness.

6. Advantages and Limitations

Advantages:

- Excellent Dimensional Stability: The primary benefit, preventing shrinkage and distortion.

- Improved Crease Resistance: Enhances garment aesthetics and easy care properties.

- Enhanced Handle and Drape: Contributes to desired fabric characteristics.

- Improved Dyeing Uniformity: Ensures level and consistent dye uptake.

- Increased Fastness: Can improve sublimation and wash fastness of some dyes.

Limitations:

- Fiber Specific: Only applicable to thermoplastic synthetic fibers. Not used for cotton, wool, silk, etc.

- High Energy Consumption: Requires significant energy to heat the stenter chambers.

- Risk of Yellowing/Degradation: Overheating can cause yellowing, brittleness, and strength loss in synthetic fibers.

- Oligomer Formation (Polyester): High temperatures can cause polyester oligomers (small polymer chains) to migrate to the fiber surface, which can cause powdery deposits, dullness, or even interfere with subsequent processes.

- Sublimation of Dyes: If post-setting is done after dyeing, dyes with poor sublimation fastness can vaporize and redeposit, leading to shade change or staining.

Heat setting is an indispensable process in the manufacturing of synthetic textiles, guaranteeing the stability, performance, and aesthetic quality demanded by modern consumers.