Lecture #23: A Deeper Dive into Dye Chemistry – Part 9: Basic Dyes (Cationic Dyes)

Welcome to Lecture #23! Today, we’re going to delve into Basic Dyes, also known as Cationic Dyes. These dyes stand in contrast to the Acid Dyes we just discussed, as they carry a positive charge and are primarily used for fibers that possess anionic (negatively charged) sites, most notably acrylic fibers. They are renowned for their exceptional brightness and brilliance of shade.

1. Introduction to Basic Dyes

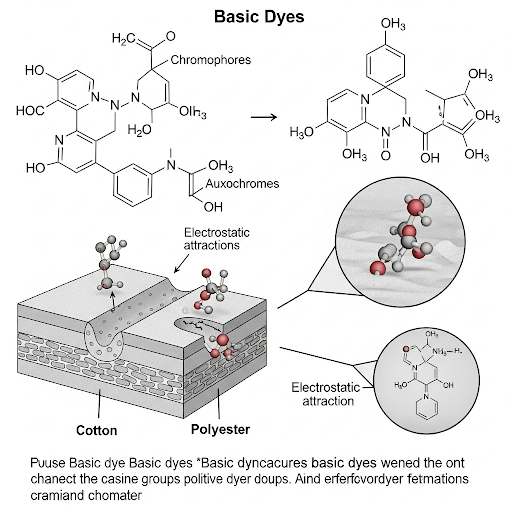

- Definition: Basic dyes are water-soluble dyes that, in solution, dissociate to form colored cations (positively charged dye ions). They are attracted to and form strong ionic bonds with anionic groups (like sulfonate or carboxyl groups) present in certain synthetic fibers or chemically modified natural fibers.

- Key Feature: Their cationic nature and their ability to produce exceptionally bright and intense shades. The strong ionic bond they form results in very good fastness properties on the fibers they are designed for.

- Primary Application: Predominantly used for acrylic fibers (e.g., Orlon, Acrilan, Dralon). They are also used for modacrylics, cationic-dyeable polyester, and historically for tannin-mordanted cotton and silk (though less common now). They are generally not suitable for regular cotton, wool, or nylon due to lack of strong anionic sites or fiber degradation concerns.

- Historical Significance: These were among the earliest synthetic dyes (e.g., Mauveine, Magenta, Methylene Blue). While initially used for natural fibers, their poor fastness on these materials led to their decline until the advent of acrylic fibers in the mid-20th century, where they found their true calling.

2. Chemical Structure of Basic Dyes

Basic dyes typically feature relatively small, highly conjugated structures that carry a delocalized positive charge.

- Chromophores: The most common chromophores include:

- Methine: (e.g., Astrazon dyes)

- Triarylmethane: (e.g., Malachite Green, Crystal Violet) known for their intense brilliance.

- Polymethine:

- Azo: (less common for basic dyes but present)

- Oxazine, Thiazine, Acridine: (e.g., Methylene Blue)

- Cationic Group: The positive charge is generally located on a quaternary ammonium group, a protonated amino group, or a delocalized system involving nitrogen atoms. This positive charge is the defining characteristic that allows them to bond with anionic sites on the fiber.

- Example (Conceptual): Dye+Cl− (Where “Dye” represents the large, colored organic cation, and Cl− is a counter-ion for solubility.)

- The charge is often stabilized by resonance across the conjugated system of the chromophore.

3. Mechanism of Dyeing (Ionic Bonding)

The dyeing mechanism of basic dyes is primarily based on ionic (electrostatic) attraction between the positively charged dye cation and the negatively charged sites on the fiber.

- Fiber Anionic Sites: Acrylic fibers are copolymers that are specifically designed to include anionic groups, typically sulfonate (−SO3−) or carboxyl (−COO−) groups, during their polymerization. These groups are permanently fixed in the fiber structure and carry a negative charge.

- Dye Cationization: When a basic dye is dissolved in water, it dissociates to form a colored dye cation and an inorganic anion (e.g., chloride, sulfate). Dye+Cl−→Dye++Cl−

- Ionic Bonding (Salt Linkage): The positively charged dye cations are strongly attracted to and form ionic bonds (salt linkages) with the negatively charged anionic sites on the acrylic fiber. Fiber−SO3−+Dye+→Fiber−SO3−Dye+

- Diffusion and Exhaustion: The dyeing process involves the diffusion of dye cations from the bath into the fiber. The rate of dyeing is significantly influenced by temperature, pH, and the presence of retarders.

- Temperature: Higher temperatures increase the kinetic energy of the dye molecules and the flexibility of the polymer chains, facilitating diffusion.

- pH: The dye bath is typically kept slightly acidic (pH 4-5) to prevent hydrolysis of the dye and to optimize the interaction with the fiber.

- Retarders: Basic dyes have a very high affinity for acrylic fibers, leading to rapid and uneven dyeing (skitteriness) if uncontrolled. Retarders (cationic surfactants or colorless basic dye look-alikes) are used to compete with the dye for the anionic sites on the fiber, thus slowing down the rate of dyeing and promoting levelness. They essentially act as temporary blocking agents.

- Fiber Structure: The relatively open and accessible structure of acrylic fibers (compared to the dense structure of polyester) allows for easier penetration of the dye molecules.

4. Dyeing Process

Basic dyes are typically applied using an exhaust dyeing method:

- Preparation: The fabric is thoroughly cleaned.

- Dye Bath Preparation: The basic dye is dissolved. Acetic acid is usually added to adjust the pH to 4-5. A retarder is often crucial, especially for initial dye uptake. Sodium sulfate can be added to control the exhaustion rate.

- Dyeing: The fabric is immersed, and the temperature is gradually raised from around 60∘C to boiling (95−100∘C) over a controlled period. The rate of temperature rise is critical for achieving levelness.

- Rinsing: After dyeing, the fabric is thoroughly rinsed to remove unfixed dye and residual chemicals.

- Aftertreatment (Optional): For very deep shades or to improve wash fastness further, a cationic fixing agent might be used, but this is less common than with acid dyes due to the inherently strong bond.

5. Fastness Properties

- Washfastness: Excellent to outstanding due to the strong ionic bond formed between the dye and the fiber.

- Lightfastness: Very good to excellent for most basic dyes on acrylics.

- Rubfastness (Crocking): Good, provided proper fixation.

- Bleaching Fastness: Generally poor to moderate. Basic dyes are often sensitive to oxidative bleaching.

- Overall: Provide shades with excellent serviceability properties, especially on acrylics.

6. Advantages and Disadvantages

Advantages:

- Exceptional Brilliance: Produce the brightest and most intense shades available on textiles.

- Excellent Fastness on Acrylics: Outstanding wash, light, and rub fastness on acrylic and modacrylic fibers.

- Cost-Effective: Often cost-effective for achieving bright, fast shades on their target fibers.

- Good Levelness (with Retarders): Can achieve good level dyeing with careful control and the use of retarders.

Disadvantages:

- Limited Fiber Applicability: Highly specific to acrylic fibers and cationic-dyeable polyesters. Not suitable for natural cellulosic or protein fibers (unless specially modified) due to lack of anionic sites or risk of fiber damage.

- Retarders Required: The very high affinity for acrylics necessitates the use of retarders and careful dyeing procedures to prevent unlevelness.

- Sensitive to pH: Can be sensitive to very high pH, leading to precipitation or decomposition of the dye.

- Effluent Issues: The dye bath effluent may contain residual dye and retarders, requiring appropriate treatment.

- Fiber Damage (if misapplied): If used on unsuitable fibers or with incorrect conditions, can cause damage or poor fastness.

Basic dyes are the cornerstone for coloring acrylic fibers, contributing to the vibrant and durable qualities of many knitted garments, carpets, and outdoor textiles. Their unique cationic nature provides a powerful example of how dye chemistry is tailored to specific fiber properties.