The Realm of High-Performance Specialty Fibers: Aramid and Carbon Fibers – Textile Fiber Lecture #25 (in a Series on Textile Fibers)

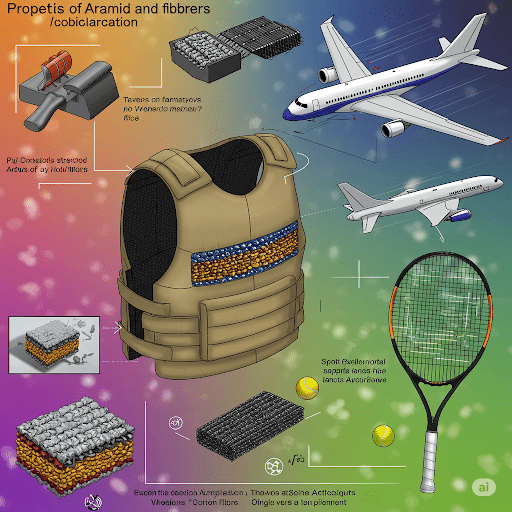

Today, we are exploring the world of Specialty Fibers, a group of high-performance fibers engineered for demanding applications where exceptional properties are required. We will focus on two prominent examples: Aramid Fibers (exemplified by Kevlar) and Carbon Fibers, examining their unique characteristics, preparation, and remarkable uses.

1. Aramid Fibers: Strength and Heat Resistance

- History and Source: Aramid fibers are synthetic polyamides characterized by highly aromatic chemical structures. The term “aramid” is a portmanteau of “aromatic polyamide.” The first aramid fiber with high performance was developed by Stephanie Kwolek at DuPont in 1965, leading to the commercial introduction of Kevlar in the early 1970s. Another significant aramid fiber is Nomex, also by DuPont, which offers excellent flame resistance.

- Preparation: Aramid fibers are typically produced through a process called solution spinning. The aromatic polyamide polymer is dissolved in a suitable solvent, and the solution is then forced through spinnerets into a coagulation bath or a heated gas stream to solidify the fibers. The fibers are then washed, dried, and often subjected to high temperatures under tension to increase their crystallinity and alignment of polymer chains, resulting in exceptional strength.

- Chemical Structure: The key to aramid fibers’ properties lies in their chemical structure. They consist of long chains of aromatic rings linked by amide groups (-CONH-). The rigid, linear nature of these aromatic polyamide chains and their ability to form strong intermolecular hydrogen bonds contribute to their high strength and thermal stability. In Kevlar, the para-orientation of the amide linkages on the benzene rings results in highly aligned, rod-like molecules that pack tightly, leading to its exceptional tensile strength. Nomex, with a meta-orientation, has better thermal resistance and flame retardancy.

- Key Properties:

- Extremely High Tensile Strength: Kevlar, in particular, has an exceptionally high strength-to-weight ratio, several times stronger than steel.

- High Modulus (Stiffness): Aramid fibers are very stiff and resist stretching.

- Excellent Thermal Stability and Heat Resistance: They can withstand high temperatures and are often flame-resistant (especially Nomex).

- Good Chemical Resistance: They are resistant to many chemicals and solvents.

- Good Cut and Abrasion Resistance: They offer protection against physical damage.

- Low Elongation to Break: They are very strong but do not stretch much.

- Applications: Due to their remarkable properties, aramid fibers are used in a wide range of high-performance applications:

- Ballistic Protection: Body armor (bulletproof vests), helmets.

- Reinforcement: Tires, fiber optic cables, composite materials in aerospace and automotive industries.

- Protective Clothing: Firefighter suits, cut-resistant gloves.

- Ropes and Cables: High-strength, lightweight cables for marine and industrial uses.

- Friction Materials: Brake linings.

2. Carbon Fibers: Lightweight Stiffness and Strength

- History and Source: Carbon fibers are fibers composed mostly of carbon atoms. The earliest carbon fibers were developed by Joseph Swan in the late 19th century for light bulb filaments. Modern high-performance carbon fibers were developed in the late 1950s and early 1960s. They are typically produced from precursor fibers such as polyacrylonitrile (PAN), rayon, or pitch.

- Preparation: The production of carbon fibers involves a complex multi-stage process called carbonization. The precursor fibers are subjected to extremely high temperatures (typically 1000-3000 °C) in an inert atmosphere. This process drives off most of the non-carbon atoms, leaving behind long chains of carbon atoms bonded together in a graphitic structure. The resulting fibers are very thin (about 5-10 micrometers in diameter). Surface treatments are often applied to improve their bonding with resins in composite materials.

- Chemical Structure: Carbon fibers consist primarily of carbon atoms arranged in a hexagonal network, similar to graphite. These layers of carbon atoms are aligned along the fiber axis, giving the fibers their high strength and stiffness in that direction. The degree of alignment and the purity of the carbon determine the final properties of the fiber.

- Key Properties:

- Extremely High Tensile Strength: Some carbon fibers have even higher tensile strength than high-strength steel.

- Very High Modulus (Stiffness): Carbon fibers are exceptionally stiff and rigid.

- Lightweight: They have a very low density.

- Excellent Fatigue Resistance: They can withstand repeated stress cycles without weakening.

- Good Chemical Resistance: They are resistant to many chemicals.

- High Electrical Conductivity: Unlike most textile fibers, carbon fibers are electrically conductive.

- High Thermal Conductivity: They can conduct heat well.

- Applications: Due to their exceptional stiffness, strength-to-weight ratio, and other unique properties, carbon fibers are used in a wide array of advanced applications:

- Aerospace: Aircraft structures (wings, fuselage), satellite components.

- Automotive: Lightweight structural components, racing car bodies.

- Sports Equipment: High-performance bicycles, golf clubs, tennis rackets.

- Reinforcement in Composites: Wind turbine blades, boat hulls.

- Medical Devices: Prosthetics, surgical instruments.

- Electronics: Conductive textiles, electromagnetic shielding.

Conclusion:

Aramid and carbon fibers represent the pinnacle of engineered textile fibers, offering exceptional performance characteristics tailored for demanding applications. Their unique chemical structures and complex manufacturing processes result in materials that push the boundaries of strength, heat resistance, stiffness, and lightweight design, making them crucial in numerous advanced industries.