Beyond the Bottom Line: The Enduring Pillars of Bangladesh’s Textile Dominance

For decades, the narrative surrounding Bangladesh’s ascendance as a global apparel powerhouse has been inextricably linked to the singular advantage of low labor costs.

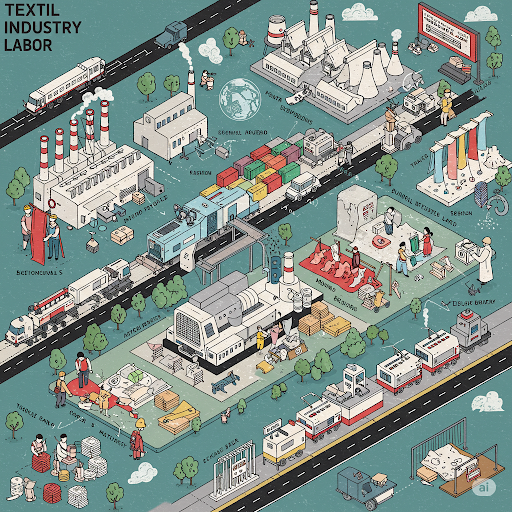

While undeniably a crucial initial catalyst, to view this sprawling, multi-billion dollar industry solely through the prism of inexpensive manpower is to fundamentally misunderstand the intricate and increasingly sophisticated ecosystem that underpins its enduring competitiveness. Like a meticulously woven fabric, Bangladesh’s textile dominance is now sustained by a complex interplay of scale, established infrastructure, growing expertise, and a resilient entrepreneurial spirit that extends far beyond the bottom line.

The sheer scale of Bangladesh’s ready-made garment (RMG) sector is a formidable advantage in itself. Decades of focused growth have cultivated an unparalleled production capacity. Thousands of factories, ranging from small workshops to sprawling industrial complexes, operate with a collective efficiency that few other nations can rival. This critical mass allows for large-volume orders to be fulfilled with remarkable speed and consistency, attracting major international brands seeking reliable and scalable manufacturing partners. The established network of ancillary industries, from yarn and fabric production (though still heavily reliant on imports) to accessories and packaging, further streamlines the production process, creating a deeply integrated supply chain within the nation’s borders. This concentrated capacity translates to economies of scale that extend beyond just labor, encompassing logistics, sourcing of local inputs, and overall operational efficiency.

Furthermore, the established infrastructure, honed over years of catering to global demands, provides a significant competitive edge. While challenges undoubtedly remain, the country has developed a substantial network of ports, transportation links, and logistical services specifically geared towards the needs of the garment industry. Chittagong Port, despite its limitations, remains a vital artery for the inflow of raw materials and the outflow of finished goods. The growth of local expertise in logistics management, customs clearance, and quality control further facilitates the smooth flow of goods within the supply chain. This embedded infrastructure, constantly being upgraded and expanded, reduces lead times and transaction costs for international buyers, making Bangladesh a more attractive sourcing destination compared to nascent industries in other regions.

Crucially, the narrative of a purely unskilled workforce is increasingly outdated. Years of experience have cultivated a deep pool of growing expertise at every level of the industry. From skilled machine operators and pattern makers to quality control specialists and factory managers, a generation has been trained and has honed its skills within the demanding environment of global apparel production. Local design capabilities are also steadily maturing, allowing Bangladeshi manufacturers to offer more than just basic CMT (Cut, Make, Trim) services and engage in more value-added production. This evolving expertise allows for greater efficiency, improved quality standards, and the ability to handle more complex and demanding orders, moving the industry gradually up the value chain.

Beyond these tangible factors, the resilient entrepreneurial spirit of the Bangladeshi people is an often-overlooked but vital component of its competitiveness. The industry is driven by a dynamic mix of established conglomerates and nimble SMEs, all constantly adapting to evolving global trends and buyer demands. This inherent flexibility and willingness to invest in upgrades, explore new technologies, and embrace sustainable practices are crucial for long-term viability. The local ownership and management of a significant portion of the industry fosters a deep understanding of the local context and a commitment to navigating challenges with agility and innovation.

Of course, the journey has not been without its hurdles. Issues related to labor rights, workplace safety, and environmental sustainability have cast a shadow and continue to demand urgent attention and continuous improvement. However, the progress made in these areas, often driven by international pressure and local initiatives, demonstrates a growing commitment to responsible manufacturing, which, in the long run, will further enhance the industry’s reputation and competitiveness.

In conclusion, while the initial advantage of competitive labor costs provided the launchpad for Bangladesh’s textile ascent, its enduring dominance is now anchored in a far more robust foundation. The immense scale of its production, the established and evolving infrastructure, the growing pool of skilled expertise, and the unwavering entrepreneurial drive have collectively forged a formidable and increasingly sophisticated industry. To view Bangladesh’s textile sector solely through the lens of “cheap labor” is to ignore the intricate tapestry of factors that have woven its success and will continue to define its position as a vital force in the global fashion landscape for years to come. The unseen threads of scale, infrastructure, expertise, and resilience are the true pillars upon which this textile titan stands.