Concluding Remarks & Future of Denim Washing: Lecture 8

Lecture Objectives:

- Summarize the key learnings from the lecture series on various denim washing machine brands.

- Discuss overarching trends and challenges facing the denim finishing industry.

- Explore the future trajectory of denim washing technologies and sustainable practices.

- Encourage critical thinking about the interplay of technology, sustainability, and market demands.

I. Recap of Key Brands and Approaches (10-12 minutes)

- Tonello:

- Pioneer of the “Laundry R(Evolution)”: Highlight their leadership in integrating ozone (ECOfree 2), nanobubble (e-Flow), and laser technologies.

- Key Contribution: Revolutionizing denim finishing by drastically reducing water, chemicals, and energy, with a strong focus on sustainable aesthetics and worker safety.

- Signature Technology: NOSTONE® for pumice-free stonewashing.

- Jeanologia:

- The Digital Transformation Leader: Emphasize their role in bringing laser technology to the forefront for dry processes, combined with G2 Ozone and e-Flow.

- Key Contribution: Driving a digital and chemical-free revolution in denim finishing, enhancing design precision and environmental responsibility.

- Signature Tool: EIM (Environmental Impact Measuring) software for quantifiable sustainability.

- Yılmak Machine:

- Robust & Efficient Workhorse: Focus on their strong build quality, high-capacity industrial washing machines, and commitment to efficiency.

- Key Contribution: Providing reliable and adaptable solutions for high-volume denim production, with a growing emphasis on water and energy efficiency.

- Market Niche: Strong presence in Turkey and emerging markets, offering practical, durable solutions.

- Kannegiesser:

- High-Volume Automation & Integration: Highlight their specialization in continuous batch washers (tunnel washers) and large-scale industrial laundry systems.

- Key Contribution: Enabling massive throughput and supreme water/energy efficiency through integrated, automated lines, essential for large-scale garment processing.

- Focus: “Laundry 4.0” principles, emphasizing automation and data analytics.

- Alliance Laundry Systems (UniMac, Speed Queen):

- Durability & Versatility: Emphasize their reputation for rugged, long-lasting industrial washer-extractors.

- Key Contribution: Providing foundational, reliable washing capabilities for denim laundries, often serving as the initial processing step before specialized finishing.

- Signature Feature: High G-force extraction for significant energy savings in drying.

- Chinese Manufacturers:

- Global Supply & Diverse Offerings: A vast segment offering a wide range of machines from cost-effective standard models to increasingly advanced and sustainable solutions.

- Key Contribution: Making textile machinery accessible globally, driving competition, and rapidly integrating new technologies.

- Consideration: Varying quality and the need for careful sourcing.

II. Overarching Trends & Challenges in Denim Washing (15-20 minutes)

- The Dominance of Sustainability:

- Driving Force: Consumer demand, brand commitments, and tightening regulations (e.g., ZDHC roadmap).

- Key Focus Areas: Drastic reduction of water, chemical, and energy consumption. Elimination of hazardous processes (e.g., sandblasting, potassium permanganate).

- Material Innovation’s Role: Complements sustainable washing (e.g., using bio-based denim).

- Automation & Digitalization:

- Labor Efficiency: Reducing reliance on manual labor, particularly for repetitive or harmful tasks.

- Consistency & Repeatability: Digital control (PLCs, software) ensures precise and consistent results across batches.

- Data-Driven Decisions: IoT sensors and analytics for optimizing processes, predictive maintenance, and sustainability reporting.

- Circular Economy Principles:

- Beyond Production: Emphasis on end-of-life solutions for denim – recycling, upcycling, repair, and resale.

- Washing for Longevity: Processes that preserve garment integrity and enable future recycling.

- Water Recycling Systems: Closed-loop water systems within laundries becoming standard.

- Supply Chain Transparency:

- Traceability: Demand for greater visibility into manufacturing and finishing processes.

- Certifications: Importance of standards like GOTS, Oeko-Tex, and bluesign.

- Cost vs. Sustainability:

- Initial Investment: Advanced sustainable technologies often require significant upfront capital.

- ROI: Discuss how long-term operational savings (water, energy, chemicals, labor) and brand reputation offset initial costs.

- Accessibility: How different tiers of manufacturers (from premium to more accessible) are addressing this balance.

III. The Future Trajectory of Denim Washing Technologies (10-12 minutes)

- Further Integration of “Dry” Technologies: Expect continued innovation in laser, ozone, and other “dry” or minimal-water finishing methods to cover a wider range of effects.

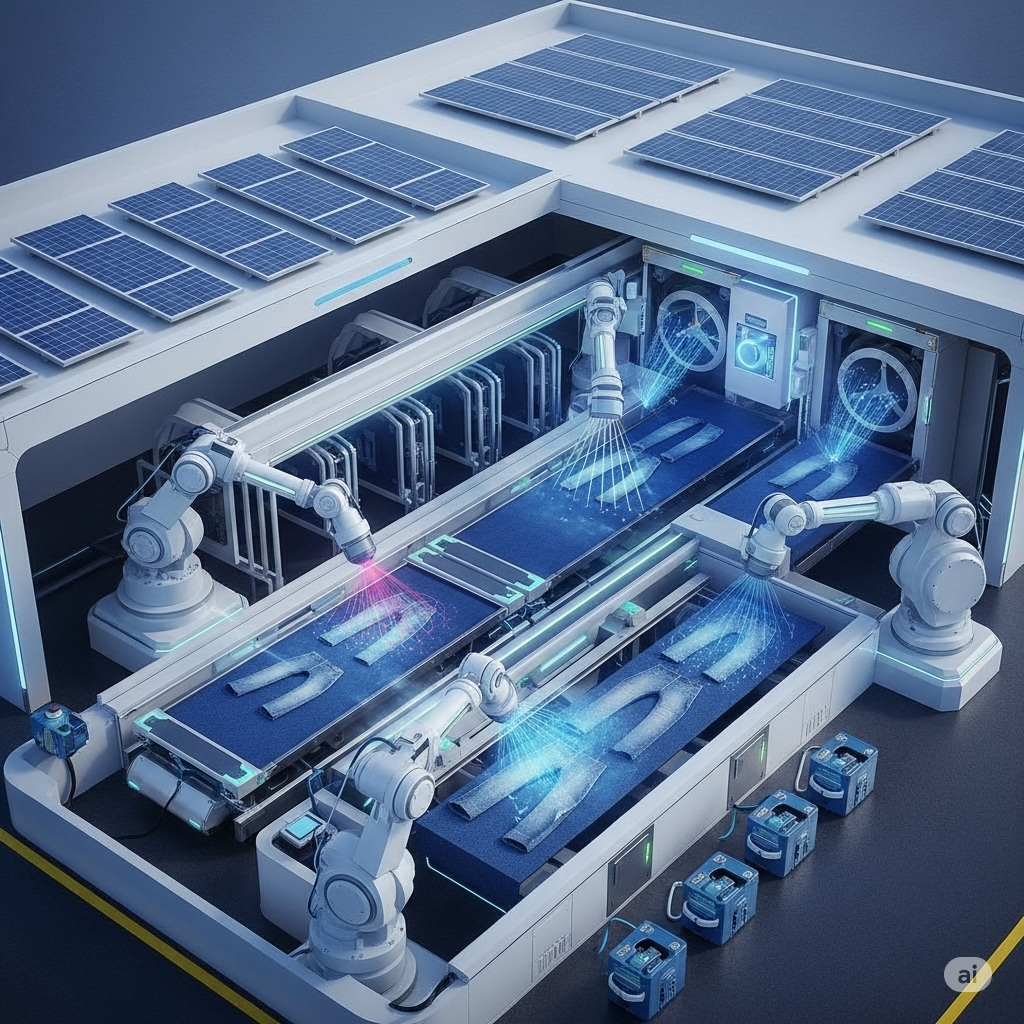

- AI & Machine Learning:

- Predictive Washing: AI optimizing wash recipes based on fabric type, desired effect, and real-time data.

- Quality Control: AI-powered visual inspection systems for faster, more accurate defect detection.

- Robotics in Laundry: Increased use of robotic arms for loading, unloading, and handling garments, especially for hot or chemical-laden processes.

- Modular & Adaptable Systems: Greater flexibility in machine design to easily adapt to new trends, smaller batch sizes, and evolving sustainability requirements.

- Decentralization vs. Consolidation: A potential dichotomy where some brands might favor small, highly specialized regional finishing hubs (closer to design/consumer), while others maintain large, centralized, highly automated facilities.

- Bio-Finishing & Novel Chemistry: Development of even more benign enzymes, microorganisms, and green chemicals for washing and dyeing.

- Water as a Commodity: Continued advancements in water treatment and recycling to achieve near-zero liquid discharge (ZLD) in all denim laundries.

IV. Concluding Thoughts & Q&A (Remaining Time)

- The Denim Paradox: How denim, historically associated with ruggedness and often wasteful production, is becoming a leader in sustainable innovation.

- Industry Responsibility: Emphasize the critical role of textile machinery manufacturers in enabling sustainable practices.

- Consumer Influence: The power of consumer demand to drive technological change and brand responsibility.

- Call to Action: Encourage students to continue researching and contributing to this exciting and rapidly evolving field.

- Open the floor for final questions and discussions.

- Discussion Prompts:

- Which of the technologies discussed do you believe will have the greatest impact on the future of denim washing? Why?

- What role do consumers play in driving the adoption of sustainable denim finishing technologies?

- What do you see as the biggest challenge for the denim industry in achieving true sustainability?

- How might future innovations in fiber science (e.g., bio-based textiles) influence denim washing technologies?