Tonello – The Laundry (R)Evolutionaries: Lecture 1

Understand Tonello’s position as a leading innovator in sustainable garment finishing.

Explore their key technologies that have revolutionized denim washing.

Discuss Tonello’s holistic approach to reducing environmental impact in denim production.

Identify the benefits and applications of Tonello’s integrated systems.

I. Introduction to Tonello

- Who is Tonello?

- Italian company with a long-standing history (founded in 1981).

- Family-owned business with a strong commitment to innovation and sustainability.

- Pioneers in garment finishing technologies, particularly for denim.

- Known for their philosophy: “The Laundry (R)Evolution” – a commitment to transforming the laundry industry towards a more sustainable and ethical future.

- Vision & Mission:

- To develop technologies that enable denim laundries to achieve authentic looks with minimal environmental impact.

- Focus on reducing water, chemicals, energy, and labor while maintaining quality and creativity.

- Global Presence: Highlight their reach and adoption by leading denim brands and laundries worldwide.

II. Core Technologies & Innovations (20-25 minutes)

This is the heart of Tonello’s contribution. Detail each technology with examples of how it benefits denim washing.

- ECOfree 2:

- Concept: Not a single machine, but an integrated process that combines multiple technologies for ultimate sustainability. It represents their flagship offering for a completely eco-friendly wash cycle.

- Components/Technologies within ECOfree 2:

- Ozone (with ECOfree 2):

- How it works: Ozonated air is introduced into the washing machine. Ozone (O3) is a powerful oxidizing agent.

- Application in Denim: Used for bleaching, desizing, and achieving vintage/authentic fade effects. It accelerates certain reactions.

- Benefits: Drastic reduction in water, chemicals (especially hypochlorite), and energy. Eliminates the need for traditional rinsing cycles for certain effects. Reduces effluent pollution.

- e-Flow (Nebulization Technology):

- How it works: Uses nanobubbles of air to carry chemicals and dyes, rather than immersing garments in large volumes of water.

- Application in Denim: For applying softeners, resins, or very small amounts of chemicals for specific effects (e.g., tinting, specific washes).

- Benefits: Reduces water consumption by up to 90% compared to conventional methods for certain processes. Minimizes chemical usage and discharge. Offers greater process control.

- Laser Systems (e.g., Tonello Laser Lab, Laser Blast):

- How it works: High-precision lasers burn off indigo dye from the denim surface.

- Application in Denim: Creating whiskers, distressing, abrasions, rips, repairs, and intricate patterns without manual sanding or harsh chemicals (e.g., potassium permanganate).

- Benefits: High precision, consistency, repeatability, reduced manual labor, zero water and chemical usage for these effects, improved worker health and safety.

- Ozone (with ECOfree 2):

- Discussion Points: How ECOfree 2 integrates these technologies for a synergistic effect. The goal of a “dry process” approach.

- NOSTONE®:

- Concept: A patented technology that completely eliminates the need for pumice stones in the stonewashing process.

- How it works: Specific mechanical action within the washing machine, combined with proprietary additives, achieves the stone-washed look without physical stones.

- Application in Denim: Achieving classic stone-washed effects.

- Benefits: Eliminates stone purchase and disposal, significantly reduces sludge (meaning less wastewater treatment), prevents damage to garments and machines, extends machine lifespan, and offers a cleaner working environment.

- Discussion Points: The environmental and operational problems associated with traditional stonewashing. How NOSTONE® addresses these.

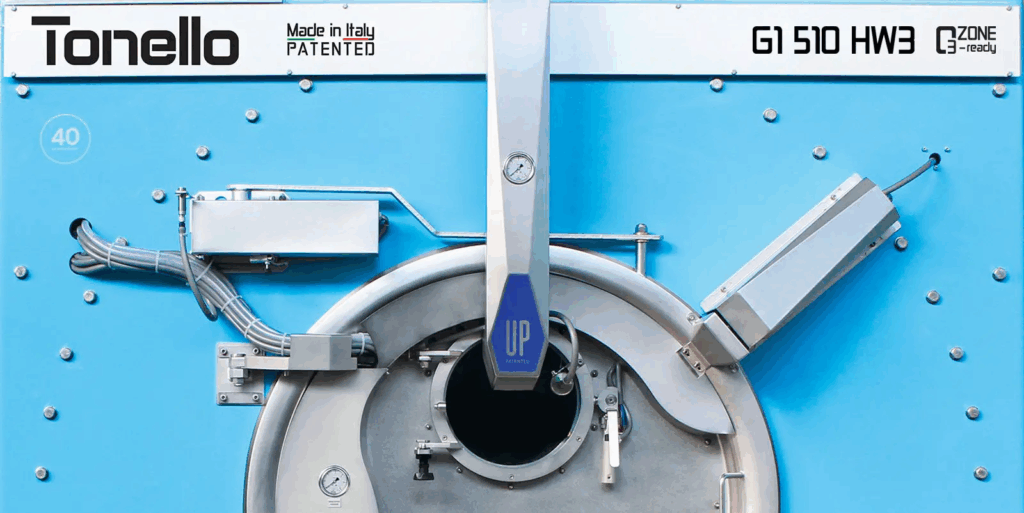

- UP (Ultra-Low Liquor Ratio):

- Concept: A highly efficient washing and dyeing system designed to operate with extremely low liquor ratios (water to fabric weight ratio).

- How it works: Advanced machine design ensures even distribution of water and chemicals with minimal volume.

- Application in Denim: General washing, dyeing, and chemical applications where maximum water savings are desired.

- Benefits: Significant water and energy savings. Reduced chemical consumption due to higher concentration in less water. Faster processing times.

- Discussion Points: The critical role of liquor ratio in textile processing sustainability.

- Core & Wake:

- Concept: Specific technologies focused on enhancing denim aesthetics and processes, often related to special finishes or improving consistency.

- Discussion Points: These are often more nuanced and might be discussed as examples of Tonello’s continuous innovation in achieving specific denim looks.

III. Tonello’s Machine Portfolio (10-15 minutes)

- Industrial Washing Machines (G1 Series):

- Features: Robust stainless steel construction, advanced programming capabilities, precise temperature and chemical dosing control, various capacities to suit different production needs.

- Integration: Designed to seamlessly integrate with their ECOfree 2, NOSTONE®, and UP technologies.

- Drying Tumblers: Energy-efficient dryers that complement their washing process.

- Other Equipment: Mention their full range of finishing equipment if time permits (e.g., specific finishing lines).

IV. Sustainability & The Laundry (R)Evolution (10-15 minutes)

- Holistic Approach: Emphasize that Tonello doesn’t just offer individual machines, but a comprehensive system aimed at transforming the entire laundry process.

- Key Sustainable Achievements:

- Drastic reduction in water consumption (up to 90% for certain processes).

- Significant decrease in chemical usage (up to 90% for specific treatments).

- Reduced energy consumption.

- Elimination of harmful substances and processes (e.g., pumice stones, potassium permanganate).

- Improved worker safety and health.

- Traceability & Transparency: How their technologies support these goals for brands.

- Case Studies/Brand Adoption (if possible): Mention prominent denim brands that use Tonello technology (e.g., via their website or industry news).

V. Challenges & Future Outlook (5-7 minutes)

- Challenges: Initial investment cost (though offset by operational savings), technical expertise required for optimal utilization.

- Future Trends: Continued innovation in automation, AI integration, closed-loop systems, and even greater water/chemical reduction. Tonello’s role in shaping these trends.

VI. Q&A and Discussion (Remaining Time)

- Open the floor for questions.

- Discussion Prompts:

- How do Tonello’s innovations challenge traditional denim washing methods?

- What are the biggest benefits for a denim laundry adopting Tonello’s integrated system?

- What role does sustainability play in a brand’s decision to invest in technology like Tonello’s?

- Are there any potential drawbacks or limitations to these advanced technologies?

This structure should provide a solid foundation for your first lecture on Tonello. Next, we can move on to Jeanologia.